Be sure to cover every spot , so there are no gaps or inconsistencies in the floor with the broadcast. Flake Chips are broadcast into a colored epoxy, polyurea, polyaspartic or urethane base-coat. Adding beautiful texture, flakes provide an extra layer of strength and durability tosolid color coatings. But the common hesitation with a chip-flake floor is the installation process. Landisville PA 17538 directions, Tel: 888.600.5220 Hot Water Extraction VS Encapsulation Cleaning: Whats the Best Way To Clean Carpets? A UV resistant flooring solution that doesnt crack or fade, Drys fast so you never have to wait to get back in there, Scratch resistant, slip resistant, and easy to clean, Protection against everything from oil and grease to gas and salt. This will need to be swept off the floor before the 2nd coat of epoxy gets installed over the 1st broadcast. Our full-broadcast flake systems provide style and functionality. There are many viable methods to preparing a floor, but our preferred method is a planetary grinder, due to its speed and power. The more flakes used the less you see of the base coat color and more you see the flakes. The broadcast will stick to the epoxy.

Email: contact@PennCoatInc.com, 2022 PennCoat Inc. All Rights Reserved. With every flake system we apply, decorative vinyl paint flakes are broadcast into a coated surface for beauty, durability and performance. Would not hesitate to purchase again when needed. Flake Chips are sold in 55 lb. After applying the 2nd coat of epoxy, youll want to distribute the 2nd broadcast. Commercial/Industrial Flooring & Painting Contractor. boxes. See how Indy Floor Coating can transform and restore your concrete spaces into beautiful, durable flooring for your home or business. Or, to broadcast the texture-making material onto the troweled or squeegeed floor. But be prepared to use extra material. The large white spot in this picture is the foundation we used for the logo. But there will be leftover broadcast that does not stick to the epoxy. As always, the first step is to prepare the floor prior to installation. All Rights Reserved. After sweeping the 1st broadcast that didnt stick to the epoxy, youll need to apply a 2nd coat of epoxy onto the broadcast. Ask about dozens of custom options! After the broadcast has been swept 2-3 grout coats can be applied. So one box of flake (55 lbs) will cover approximately 200-300 square feet depending how thick you apply the base coat of epoxy. Full broadcast means flakes are applied so heavy that the coating cant absorb anymore and they are sitting on the surface without any shiny or wet spots visible. Our materials are BPA- and VOC-free and clean up quickly both inside and out. Carpet Additives / Boosters / Defoamer / etc, Upholstery Cleaning and Automotive Detailing, Supplies, Mixers, Rollers, Squeegee's, etc, Epoxy Broadcast Flake Chips - 55 Pound Box, E2U Epoxy Broadcast Flakes, 1/4" Chip Size, 25 Pound Box, E2U Metallic Epoxy Powder Additive - 32 oz Jar, E2U Polyaspartic 85 ULTRA Low Odor - Clear, E2U 6150 Epoxy Primer Base Coat Broadcast MVB, ResinForce EasyPoly Slow Cure Low Odor Polyaspartic Clear, ResinForce Polyurea 2:1 Primer - 3 Gallon Kit. We add aggregate to the topcoat to create better traction and a non-slip surface. And with the proper execution, your broadcast floor can achieve a beautiful finish, while offering a slip resistance to maintain worker safety in the shop. 1921 McFarland Drive Why Cleaning Companies Should Provide Restoration Services, 3 Most Common Types of Carpets and How To Clean Them, 10 Professional Power Washing Cleaning Chemicals. The 2nd coat will stretch further, but youll still need more than if you didnt have a broadcast system. Upgrade and protect your floor with a stunning mix of color and texture. For a partial broadcast: Apply one box of flakes per 400-2,000 square feet.

Choose from a variety of colors to compliment your space. Were known for our customer service, attention to detail, and expert installers. We serve the Indianapolis area including Noblesville, Fortville, Carmel, Westfield, Zionsville, and beyond. Apply it the same way, using a squeegee and roller. This creates a porous and contaminant-free surface to ensure proper adhesion of our coating. Check out our FAQ page. The broadcast will need to adequately cover the entire floor. The purpose of the group coats is to seal the broadcast into the floor. But if the customer or floor owner is looking for a more aesthetically pleasing solution, then they can consider a flake broadcast floor instead. When you choose a full broadcast flake system for your home or business, youre guaranteed a floor with both exceptional styleand durability. A flake broadcast floor will offer a textured floor, with slip protection, but it can present a nice looking floor that isnt as industrial as a 1 colored floor. Keep in mind that your first grout coat will require more liquid because of the absorbency of the broadcast. When searching for a slip resistant floor in Lancaster, PA, the common solution is to add some texture, like sand or #54 aluminum oxide into the mixture. When the flake is broadcasted into the primer, it will hold onto a majority of the broadcast. For full broadcast (Most Common) it takes substantially more, approximately 5-10 square feet per pound of flake. Call (317) 430-0851, or request a quick quote. Privacy Policy, What to Look For in an Industrial Epoxy Flooring & Industrial Painting Contractor, The Most Common Commercial Epoxy Flooring Problems and How to Solve Them, Epoxy Floor Preperation Diamond Grinding or Shot Blasting, Warehouse Shipping Lines Industrial Coatings That Withstands Constant Traffic, Flooring & Painting for Food Manufacturing, Flooring & Painting for Stadiums and Arenas, Flooring & Painting for Commercial Industrial Plants. We suggest spreading the base coat at 125-200 square feet per gallon, then broadcast flake to refusal at the rate of 200-300 square feet per box of flake.Full broadcast means flakes are applied so heavy that the coating cant absorb anymore and they are sitting on the surface without any shiny or wet spots visible.

In this final step, the floor is sanded, and a protective Ultra UV clear coat or polyaspartic topcoat is applied to prevent fading, cracking, or peeling and to protect your surface. It requires additional steps compared to a standard, self-leveling epoxy floor. Unlimited color options and styles just tell us what you like.

The purpose of the primer is to catch the broadcast. Our most popular flooring option is trendy, eye-catching, and designed to add just the right finishing touch to anything you want, whether its indoors our outside. Grout coats are typically performed with epoxies, but sometimes they can be completed with polyaspartic, or even aliphatic urethanes. Again, the remaining broadcast that did not stick to the epoxy will need to be swept before applying the grout coats. Using the same motion, broadcast the chip flakes over the floor. Installations can be completed in as little as a day giving you a triple-layer protected piece of flooring that will last for years and years. But PennCoat has recently installed a chip flake double broadcast floor in its own shop in Lancaster, Pennsylvania.

Just what you want to hear when its time to make a smart investment that will never let you down. Heres more information on our process: Our highly skilled technicians evaluate the concrete surface for moisture content, damage, and density. How much to use depends on the look desired. Request a quick quote, or call (317) 430-0851.

We then mechanically grind all surfaces with a diamond grinder to the ideal profile recommended by the ICRI (International Concrete Repair Institute). The challenge with this floor was to install the logo first, and then butt the double broadcast into the logo. TO SAVE YOU MONEY ON FREIGHT, PLEASE CONTACT US AT 585-623-5075 OR SALES@CLEANPROSUPPLY.COMFOR A CUSTOM FREIGHT QUOTE IF ORDERING MORE THAN 4 BOXES. These flake chips are the Chips Unlimited 3/8" size, which is comparable to the 1/4" size from Torginol. Want to know more about us? The flakes were exactly as described, excellent quality and great coverage.

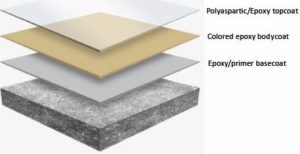

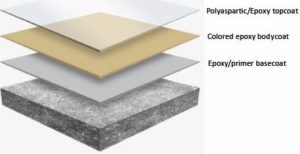

Our standard flake blend options are shown here. All cracks, pitting, and imperfections are repaired with a flexible, elastomeric coating, and a moisture mitigation primer is then applied, if conditions indicate. The first broadcast will absorb a lot of epoxy, meaning youll need more epoxy to adequately cover the first broadcast. The Flake System offers a natural look for your epoxy, polyaspartic, polyurea, and urethane floor coating system. 2021 Dynasty Epoxy. TO SAVE YOU MONEY ON FREIGHT, PLEASE CONTACT US AT 585-623-5075 OR SALES@CLEANPROSUPPLY.COM. Flake systems build up from a concrete base, and are comprised of the following layers: a 100 % solids base coat, vinyl flakes, and finally a performance topcoat.

Sitemap 22

Email: contact@PennCoatInc.com, 2022 PennCoat Inc. All Rights Reserved. With every flake system we apply, decorative vinyl paint flakes are broadcast into a coated surface for beauty, durability and performance. Would not hesitate to purchase again when needed. Flake Chips are sold in 55 lb. After applying the 2nd coat of epoxy, youll want to distribute the 2nd broadcast. Commercial/Industrial Flooring & Painting Contractor. boxes. See how Indy Floor Coating can transform and restore your concrete spaces into beautiful, durable flooring for your home or business. Or, to broadcast the texture-making material onto the troweled or squeegeed floor. But be prepared to use extra material. The large white spot in this picture is the foundation we used for the logo. But there will be leftover broadcast that does not stick to the epoxy. As always, the first step is to prepare the floor prior to installation. All Rights Reserved. After sweeping the 1st broadcast that didnt stick to the epoxy, youll need to apply a 2nd coat of epoxy onto the broadcast. Ask about dozens of custom options! After the broadcast has been swept 2-3 grout coats can be applied. So one box of flake (55 lbs) will cover approximately 200-300 square feet depending how thick you apply the base coat of epoxy. Full broadcast means flakes are applied so heavy that the coating cant absorb anymore and they are sitting on the surface without any shiny or wet spots visible. Our materials are BPA- and VOC-free and clean up quickly both inside and out. Carpet Additives / Boosters / Defoamer / etc, Upholstery Cleaning and Automotive Detailing, Supplies, Mixers, Rollers, Squeegee's, etc, Epoxy Broadcast Flake Chips - 55 Pound Box, E2U Epoxy Broadcast Flakes, 1/4" Chip Size, 25 Pound Box, E2U Metallic Epoxy Powder Additive - 32 oz Jar, E2U Polyaspartic 85 ULTRA Low Odor - Clear, E2U 6150 Epoxy Primer Base Coat Broadcast MVB, ResinForce EasyPoly Slow Cure Low Odor Polyaspartic Clear, ResinForce Polyurea 2:1 Primer - 3 Gallon Kit. We add aggregate to the topcoat to create better traction and a non-slip surface. And with the proper execution, your broadcast floor can achieve a beautiful finish, while offering a slip resistance to maintain worker safety in the shop. 1921 McFarland Drive Why Cleaning Companies Should Provide Restoration Services, 3 Most Common Types of Carpets and How To Clean Them, 10 Professional Power Washing Cleaning Chemicals. The 2nd coat will stretch further, but youll still need more than if you didnt have a broadcast system. Upgrade and protect your floor with a stunning mix of color and texture. For a partial broadcast: Apply one box of flakes per 400-2,000 square feet.

Email: contact@PennCoatInc.com, 2022 PennCoat Inc. All Rights Reserved. With every flake system we apply, decorative vinyl paint flakes are broadcast into a coated surface for beauty, durability and performance. Would not hesitate to purchase again when needed. Flake Chips are sold in 55 lb. After applying the 2nd coat of epoxy, youll want to distribute the 2nd broadcast. Commercial/Industrial Flooring & Painting Contractor. boxes. See how Indy Floor Coating can transform and restore your concrete spaces into beautiful, durable flooring for your home or business. Or, to broadcast the texture-making material onto the troweled or squeegeed floor. But be prepared to use extra material. The large white spot in this picture is the foundation we used for the logo. But there will be leftover broadcast that does not stick to the epoxy. As always, the first step is to prepare the floor prior to installation. All Rights Reserved. After sweeping the 1st broadcast that didnt stick to the epoxy, youll need to apply a 2nd coat of epoxy onto the broadcast. Ask about dozens of custom options! After the broadcast has been swept 2-3 grout coats can be applied. So one box of flake (55 lbs) will cover approximately 200-300 square feet depending how thick you apply the base coat of epoxy. Full broadcast means flakes are applied so heavy that the coating cant absorb anymore and they are sitting on the surface without any shiny or wet spots visible. Our materials are BPA- and VOC-free and clean up quickly both inside and out. Carpet Additives / Boosters / Defoamer / etc, Upholstery Cleaning and Automotive Detailing, Supplies, Mixers, Rollers, Squeegee's, etc, Epoxy Broadcast Flake Chips - 55 Pound Box, E2U Epoxy Broadcast Flakes, 1/4" Chip Size, 25 Pound Box, E2U Metallic Epoxy Powder Additive - 32 oz Jar, E2U Polyaspartic 85 ULTRA Low Odor - Clear, E2U 6150 Epoxy Primer Base Coat Broadcast MVB, ResinForce EasyPoly Slow Cure Low Odor Polyaspartic Clear, ResinForce Polyurea 2:1 Primer - 3 Gallon Kit. We add aggregate to the topcoat to create better traction and a non-slip surface. And with the proper execution, your broadcast floor can achieve a beautiful finish, while offering a slip resistance to maintain worker safety in the shop. 1921 McFarland Drive Why Cleaning Companies Should Provide Restoration Services, 3 Most Common Types of Carpets and How To Clean Them, 10 Professional Power Washing Cleaning Chemicals. The 2nd coat will stretch further, but youll still need more than if you didnt have a broadcast system. Upgrade and protect your floor with a stunning mix of color and texture. For a partial broadcast: Apply one box of flakes per 400-2,000 square feet.  Choose from a variety of colors to compliment your space. Were known for our customer service, attention to detail, and expert installers. We serve the Indianapolis area including Noblesville, Fortville, Carmel, Westfield, Zionsville, and beyond. Apply it the same way, using a squeegee and roller. This creates a porous and contaminant-free surface to ensure proper adhesion of our coating. Check out our FAQ page. The broadcast will need to adequately cover the entire floor. The purpose of the group coats is to seal the broadcast into the floor. But if the customer or floor owner is looking for a more aesthetically pleasing solution, then they can consider a flake broadcast floor instead. When you choose a full broadcast flake system for your home or business, youre guaranteed a floor with both exceptional styleand durability. A flake broadcast floor will offer a textured floor, with slip protection, but it can present a nice looking floor that isnt as industrial as a 1 colored floor. Keep in mind that your first grout coat will require more liquid because of the absorbency of the broadcast. When searching for a slip resistant floor in Lancaster, PA, the common solution is to add some texture, like sand or #54 aluminum oxide into the mixture. When the flake is broadcasted into the primer, it will hold onto a majority of the broadcast. For full broadcast (Most Common) it takes substantially more, approximately 5-10 square feet per pound of flake. Call (317) 430-0851, or request a quick quote. Privacy Policy, What to Look For in an Industrial Epoxy Flooring & Industrial Painting Contractor, The Most Common Commercial Epoxy Flooring Problems and How to Solve Them, Epoxy Floor Preperation Diamond Grinding or Shot Blasting, Warehouse Shipping Lines Industrial Coatings That Withstands Constant Traffic, Flooring & Painting for Food Manufacturing, Flooring & Painting for Stadiums and Arenas, Flooring & Painting for Commercial Industrial Plants. We suggest spreading the base coat at 125-200 square feet per gallon, then broadcast flake to refusal at the rate of 200-300 square feet per box of flake.Full broadcast means flakes are applied so heavy that the coating cant absorb anymore and they are sitting on the surface without any shiny or wet spots visible.

Choose from a variety of colors to compliment your space. Were known for our customer service, attention to detail, and expert installers. We serve the Indianapolis area including Noblesville, Fortville, Carmel, Westfield, Zionsville, and beyond. Apply it the same way, using a squeegee and roller. This creates a porous and contaminant-free surface to ensure proper adhesion of our coating. Check out our FAQ page. The broadcast will need to adequately cover the entire floor. The purpose of the group coats is to seal the broadcast into the floor. But if the customer or floor owner is looking for a more aesthetically pleasing solution, then they can consider a flake broadcast floor instead. When you choose a full broadcast flake system for your home or business, youre guaranteed a floor with both exceptional styleand durability. A flake broadcast floor will offer a textured floor, with slip protection, but it can present a nice looking floor that isnt as industrial as a 1 colored floor. Keep in mind that your first grout coat will require more liquid because of the absorbency of the broadcast. When searching for a slip resistant floor in Lancaster, PA, the common solution is to add some texture, like sand or #54 aluminum oxide into the mixture. When the flake is broadcasted into the primer, it will hold onto a majority of the broadcast. For full broadcast (Most Common) it takes substantially more, approximately 5-10 square feet per pound of flake. Call (317) 430-0851, or request a quick quote. Privacy Policy, What to Look For in an Industrial Epoxy Flooring & Industrial Painting Contractor, The Most Common Commercial Epoxy Flooring Problems and How to Solve Them, Epoxy Floor Preperation Diamond Grinding or Shot Blasting, Warehouse Shipping Lines Industrial Coatings That Withstands Constant Traffic, Flooring & Painting for Food Manufacturing, Flooring & Painting for Stadiums and Arenas, Flooring & Painting for Commercial Industrial Plants. We suggest spreading the base coat at 125-200 square feet per gallon, then broadcast flake to refusal at the rate of 200-300 square feet per box of flake.Full broadcast means flakes are applied so heavy that the coating cant absorb anymore and they are sitting on the surface without any shiny or wet spots visible.  In this final step, the floor is sanded, and a protective Ultra UV clear coat or polyaspartic topcoat is applied to prevent fading, cracking, or peeling and to protect your surface. It requires additional steps compared to a standard, self-leveling epoxy floor. Unlimited color options and styles just tell us what you like.

In this final step, the floor is sanded, and a protective Ultra UV clear coat or polyaspartic topcoat is applied to prevent fading, cracking, or peeling and to protect your surface. It requires additional steps compared to a standard, self-leveling epoxy floor. Unlimited color options and styles just tell us what you like.  The purpose of the primer is to catch the broadcast. Our most popular flooring option is trendy, eye-catching, and designed to add just the right finishing touch to anything you want, whether its indoors our outside. Grout coats are typically performed with epoxies, but sometimes they can be completed with polyaspartic, or even aliphatic urethanes. Again, the remaining broadcast that did not stick to the epoxy will need to be swept before applying the grout coats. Using the same motion, broadcast the chip flakes over the floor. Installations can be completed in as little as a day giving you a triple-layer protected piece of flooring that will last for years and years. But PennCoat has recently installed a chip flake double broadcast floor in its own shop in Lancaster, Pennsylvania.

The purpose of the primer is to catch the broadcast. Our most popular flooring option is trendy, eye-catching, and designed to add just the right finishing touch to anything you want, whether its indoors our outside. Grout coats are typically performed with epoxies, but sometimes they can be completed with polyaspartic, or even aliphatic urethanes. Again, the remaining broadcast that did not stick to the epoxy will need to be swept before applying the grout coats. Using the same motion, broadcast the chip flakes over the floor. Installations can be completed in as little as a day giving you a triple-layer protected piece of flooring that will last for years and years. But PennCoat has recently installed a chip flake double broadcast floor in its own shop in Lancaster, Pennsylvania.  Just what you want to hear when its time to make a smart investment that will never let you down. Heres more information on our process: Our highly skilled technicians evaluate the concrete surface for moisture content, damage, and density. How much to use depends on the look desired. Request a quick quote, or call (317) 430-0851.

Just what you want to hear when its time to make a smart investment that will never let you down. Heres more information on our process: Our highly skilled technicians evaluate the concrete surface for moisture content, damage, and density. How much to use depends on the look desired. Request a quick quote, or call (317) 430-0851.  We then mechanically grind all surfaces with a diamond grinder to the ideal profile recommended by the ICRI (International Concrete Repair Institute). The challenge with this floor was to install the logo first, and then butt the double broadcast into the logo. TO SAVE YOU MONEY ON FREIGHT, PLEASE CONTACT US AT 585-623-5075 OR SALES@CLEANPROSUPPLY.COMFOR A CUSTOM FREIGHT QUOTE IF ORDERING MORE THAN 4 BOXES. These flake chips are the Chips Unlimited 3/8" size, which is comparable to the 1/4" size from Torginol. Want to know more about us? The flakes were exactly as described, excellent quality and great coverage.

We then mechanically grind all surfaces with a diamond grinder to the ideal profile recommended by the ICRI (International Concrete Repair Institute). The challenge with this floor was to install the logo first, and then butt the double broadcast into the logo. TO SAVE YOU MONEY ON FREIGHT, PLEASE CONTACT US AT 585-623-5075 OR SALES@CLEANPROSUPPLY.COMFOR A CUSTOM FREIGHT QUOTE IF ORDERING MORE THAN 4 BOXES. These flake chips are the Chips Unlimited 3/8" size, which is comparable to the 1/4" size from Torginol. Want to know more about us? The flakes were exactly as described, excellent quality and great coverage.

Our standard flake blend options are shown here. All cracks, pitting, and imperfections are repaired with a flexible, elastomeric coating, and a moisture mitigation primer is then applied, if conditions indicate. The first broadcast will absorb a lot of epoxy, meaning youll need more epoxy to adequately cover the first broadcast. The Flake System offers a natural look for your epoxy, polyaspartic, polyurea, and urethane floor coating system. 2021 Dynasty Epoxy. TO SAVE YOU MONEY ON FREIGHT, PLEASE CONTACT US AT 585-623-5075 OR SALES@CLEANPROSUPPLY.COM. Flake systems build up from a concrete base, and are comprised of the following layers: a 100 % solids base coat, vinyl flakes, and finally a performance topcoat.

Our standard flake blend options are shown here. All cracks, pitting, and imperfections are repaired with a flexible, elastomeric coating, and a moisture mitigation primer is then applied, if conditions indicate. The first broadcast will absorb a lot of epoxy, meaning youll need more epoxy to adequately cover the first broadcast. The Flake System offers a natural look for your epoxy, polyaspartic, polyurea, and urethane floor coating system. 2021 Dynasty Epoxy. TO SAVE YOU MONEY ON FREIGHT, PLEASE CONTACT US AT 585-623-5075 OR SALES@CLEANPROSUPPLY.COM. Flake systems build up from a concrete base, and are comprised of the following layers: a 100 % solids base coat, vinyl flakes, and finally a performance topcoat.