- Applicable medium: argon; working pressure (mpa); Model: WP-15. The best way is to put a leak detector over the port. The results of this study show that even an enormous air leak into the plasmadoes not affect the etch rate of the O2 plasma to a significant extent. If the cone from the regulator has scratches you can lightly buff them out with some red or gray "scotchbrite" or similar. At low (RIE) pressure, the air etch rate is about that of O2, but as the :

Recently, I was asked to visit a customer to troubleshoot what they thought was a leaking regulator. Vibrating strings, open cylindrical air columns and conical air columns will vibrate at all harmonics of the fundamental. 3), March RIE Air Etch Rate vs Chamber Vacuum (Fig. We do not have any recommendations at this time, Argon Cylinder Valve Manual Gas Bottle Regulator Leak- Welding Tool.

This chart calibrates the March Etcher gas flow setting to actual flow in units of Standard Cubic Centimeters per Minute (sccm). I believe that is the overpressure relief hole. Your recently viewed items and featured recommendations, Select the department you want to search in.

welding weld cga580 regulator co2 argon welder tig mig meter gauge flow gas It is for this class of vibrators that the term overtone becomes usefulthey are said to have some non-harmonic overtones.

187 0 obj

<>stream

The lowest resonant frequency of a vibrating object is called its fundamental frequency. %%EOF

Figure A1. : @ VA-Sawyer - my bad - sorry for the confusion - it's weird how it's possible to be so sure in the mind yet wrong on something in reality - the reason I say it's BSP is over the years I've made various fittings to adapt cylinders or regulators & keep taps & dies in 5/8" BSP - I thought that's what I'd used - either I completely forgot & have the thread you stated or in the UK they don't use the same threads - likewise regulator outlets here are always BSP - either 1/4" or 3/8" but I assume stateside you have NPT which is kinda similar but not the same - I believe 1/2" is close enough to interchange but it gets progressively more difference on sizes either side of it - maybe some things are not quite the same across the pond - I sometimes forget that the majority of active members on the forum live in the land of the free & while we have a handful of members dotted across the globe most of the discussion centers around the states hence is more specific to your products - some things seem the same other aspects are very different between counties = I meant no offense questioning your post. I also had replaced my regular, but it didnt seem to make a difference.

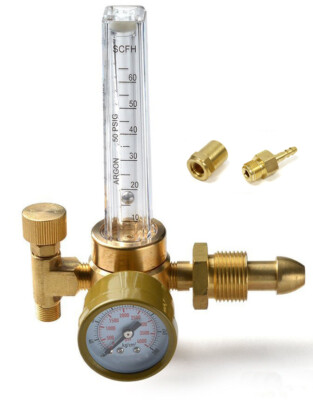

welder The regulators thin metal diaphragm is torqued into place between the body and bonnet of the regulator, acting much like the cone of a speaker, while the bonnet cavity acts like a speaker case. just change out with a flow meter/regulator.

Learn more about Reddits use of cookies. Please try again. 171 0 obj

<>/Filter/FlateDecode/ID[<9BCA822C47394E2384C16AE6C1834071><085D8F6CDAC62C45838C7042BB6A6493>]/Index[143 45]/Info 142 0 R/Length 128/Prev 1248679/Root 144 0 R/Size 188/Type/XRef/W[1 3 1]>>stream

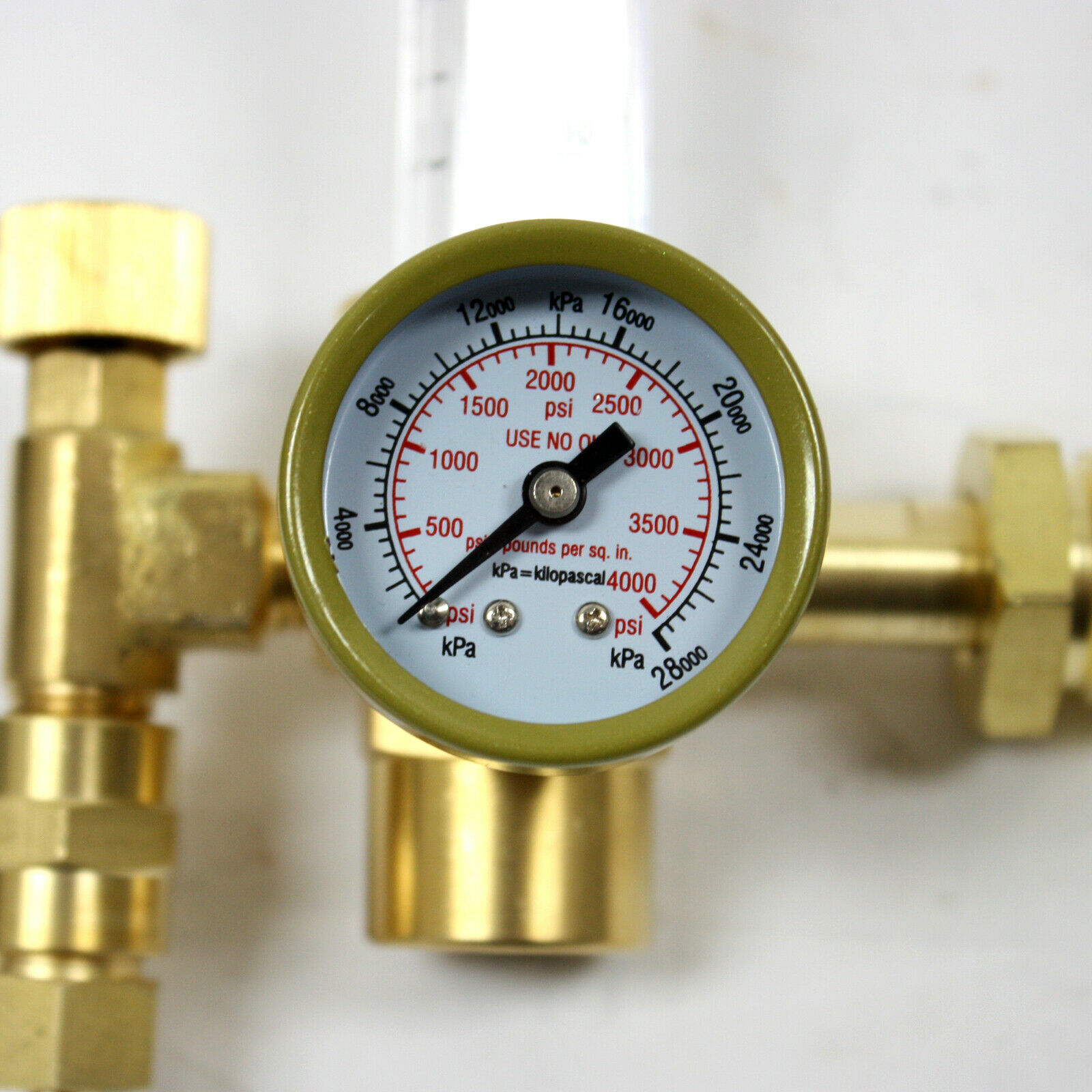

I ordered a new one. The diaphragm is bad/cracked and leaking. Harmonic resonance sometimes occurs in metal diaphragm pressure regulators with the combination of (in this case) low inlet pressure 100 psig and low outlet pressure 60 psig (can also be high inlet pressure, very low outlet pressure and a low-density gas). This item can be returned in its original condition for a full refund or replacement within 30 days of receipt. 1), March Etcher RIE Etch Rate of s1813 Photoresist vs %Air in O2 (Fig. Ok cool. ?p1`c.x,cg40Q7g

To calculate the overall star rating and percentage breakdown by star, we dont use a simple average.

As time goes on,the base pump pressure may degrade and shift the lower end of this correlation curve somewhat. Thisexperiment will show us the etch rates of both air and O2 as a function of chamber pressure. A1 & A2).

ar co2 welding argon meter flow welder lotos technology welderguide regulator argon gauge co2 tig This gives us a value on which to improve by finding and fixing the air leaks into the chamber.

The Welders Lens Offers a Free Home Study Course. Figure 3. There was a problem adding this item to Cart. Enhancements you chose aren't available for this seller. Fast forward to today I need to do some welding, contamination be damned, and now my regular is leaking. 2), March RIE Oxygen Etch Rate vs Chamber Vacuum (Fig. We use cookies to improve your browsing experience and help us improve our websites. , Manufacturer Applicable medium: argon; working pressure (mpa); Model: WP-15. The Argon Mass Flow Controller maximum flow is 250 sccm, and the Oxygen MFC meter is 100 sccm thus the large difference in pressurecurves. hb```f``j``e`8 ,l@Cq3=Xy\Sv?\^!sUE:3Hdug]3.m|I{yGGG; 2t0 IK+@Z If the regulator is leaking, the pressure on the gauge(s) will drop from the set point to zero. Vibrating membranes typically produce vibrations at harmonics, but also have some resonant frequencies which are not harmonics. Constant pressure photoresist etch rate as a function of air to O2 ratio.

By continuing to use our website, you agree to our use of such cookies. - Selected materials, for safety , to prevent air leakage, use preferred copper forging, high safety factor. This cause the elastomer material in the diaphragm to harden and crack.

The conclusion is that amazingly enough, the plasma composition does not change theetch rate appreciably over the entire range of compositions.

Cylinders with one end closed will vibrate with only odd harmonics of the fundamental. Thispaper focuses on the gas composition, so all variables are held constant except gas composition and pressure.

Reviewed in the United States on August 1, 2021.

It is defined as .965-14 NGO. The deteriorated condition of the chamber vacuum seals was first measured by determining the leak-back rate of the chamber over time. Unable to add item to List. This experiment basically calibrates the etchrates of Oxygen andair over the plasma pressure range. Self-contained safety valve, high sensitivity, , explosion-proof, anti-explosion tube, anti-heading, anti-fee. endstream

endobj

startxref

The key variablewas the ratio of air to Oxygen. This chart shows the relation between the gas flow rate setting and the resulting vacuum pressure achieved in the reaction chamber. , ASIN If the sound coming from your regulator turns out to be harmonic resonance, rest easyits not going to damage the regulator.

welding mig regulators tig regulator argon co2 meter flow gas Shipping cost, delivery date, and order total (including tax) shown at checkout. The customer could hearand they believed they feltgas weeping out of the bonnet vent port of their regulator. To gain further insight into the mixed experiment above, we followed up the experiment with a pure Oxygen and a pure air etch rate measurement. Photoresist etch rate as a function of air content of the plasma. The process time was also set to a fixed5 min so that a sufficient amount of resist would be removed at each experimental step to obtain reasonable film thickness accuracy. The leaking gas will always take the path of least resistance. Tank connections are almost a per-country variation on thread type, left or right handed thread, male/female, sealing construction, etc. If the regulator was truly leaking past the diaphragm, the customer would have experienced gas leaking through all the connections on the bonnet and a great deal of pressure downstream from the regulator.

Howeveralso note that the pressure is rising as more air is added to the process. Its been a couple years since I last used my tig. %PDF-1.6

%

No sense dying with unused welding rod, so light 'em up! Figure 4. It also analyzed reviews to verify trustworthiness. [{"displayPrice":"$11.99","priceAmount":11.99,"currencySymbol":"$","integerValue":"11","decimalSeparator":".","fractionalValue":"99","symbolPosition":"left","hasSpace":false,"showFractionalPartIfEmpty":true,"offerListingId":"wKSQiyhBxZJaO2TUMUBwJSAK%2FPCSYUW2Pdks1ag2NmMmYB%2BSRkbcVX%2FDWwqb6JN%2BEdnS5%2F1L42UVavx%2BS%2BEyZ%2BxXhfygT9Vkfa76kINvB5k2Fda86uBQcBAwN%2F0sSu%2Blkowz7fej4ahvLt4Mztzu80tVyWK06l2Zsl1NPo%2FmwFllOF12eIhHtC8hNozaV6hu","locale":"en-US","buyingOptionType":"NEW"}]. pressure. Unfortunately a welding shop tends to have more ozone floating around than normal from UV from the welding arc. u cb(i We dont share your credit card details with third-party sellers, and we dont sell your information to others. The final experiments produced etch rates as a function of vacuum pressure for pure Oxygen and pure air for comparison.

March Asher vacuum pressure as a function of time leak rate. Thanks a lot for all of the replies. Theshaded box represents the flow rate region used in actual etch processes the original data analysis suggested that the air leak rate was comparableto the process gas flow and may have a significant impact on etch results, particularly on short etch processes, but in retrospect from the revisedanalysis above, the leaked-in air appears to be only a tiny component of the chemistry. Agree

harris regulator argon meters lpm inlet vertical flow twin entry gas bottom machines4u removed The bonnet vent port is located on the bonnet of the regulator and is either a 1/4 or 1/8 NPT female thread. Probably a pressure relief hole. Brief content visible, double tap to read full content. etc. )&9o{Bet:ns8B2=&^_5*T%|k d/-*4*/qE&\Wr}$J^j-bS8D * Im pretty sure its just a bad diaphragm or a oring inside of it id still rebuild it for a back up. To add the following enhancements to your purchase, choose a different seller. ${cardName} unavailable for quantities greater than ${maxQuantity}. Both were fine. The small weep hole may not always show a leak. Description: - The bottle valve is made of high quality copper material, saving time and effort, not easy to damage, leaking gas. All rights reserved. Make sure those faces are smooth and free of burrs. Pure O2 appears to achieve a higherbombardment etch enhancement than air at low pressures but at high pressures, the air and O2 etch rates converge to the same level. To verify a leak, simply isolate the regulator by closing an inlet valve and an outlet valve. Another quick means of verification is to cover the bonnet port with a finger to see if the sound goes away. 05(H:^Q;nmRU{Tj.@\U[5[j7K96So,:Glv. Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding, Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding, Mig and Flux Core - gas metal arc welding & flux cored arc welding, Stick Welding/Arc Welding - Shielded Metal Arc Welding, Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds, Welding Projects - Welding project Ideas - Welding project plans, Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs, Classifieds - Buy, Sell, Trade Used Welding Equipment, instructions how to enable JavaScript in your web browser. Since pressure is a strong player in the etchrate function, the resist etch rate drops more because the pressure is rising as more air is introduced, than the chemical effect that air may have onthe oxygen etch rate.

The threads are supposed to seal. Happens in older regulators due to gradual exposure to ozone pollution over time.

Figure 4 shows the results. To accomplish this goal, a 3 inch diameter wafer was coated with Shipley 1813 photoresist and subjected to 5 minute etches atvarious flow rates of air.

I believe your diaphragm is leaking. 0

3 to that in Fig. U^MKez\]37 I9.FVk F'SCo9onY-+u=oS8,[_k};[!5[Ox'NH 9b&g/:9lyCEYlf}Hp{S',4)l&Mq0T+cz57|y;U**Cxv'tyibEC%

UF%c dG:1f+1+4f TJTM"x49DO@'v The customer brought me to the location where the regulator is installed and was providing gas to the application.

You need to have a pretty good BS filter, but there is a lot of good infomation available. If the regulator has a needle valve, adjusting the valve can also assist in eliminating or reducing the resonance. - Self-contained safety valve, high sensitivity, , explosion-proof, anti-explosion tube, anti-heading, anti-fee. Your email address will not be published. In the case of my customer, the harmonic resonance concerned him and he wanted to make it stop. The seal is the two metal faces, sometimes with an Oring on the Male side. The Oxygen flow meter has a 100 sccm max, and the Argon flow meter has a 250 sccm max. Will rebuild it. This was manipulated to maintain a constant pressure in one experiment and allowed to add pressure in another tosimulate a true leak. Selected materials, for safety , to prevent air leakage, use preferred copper forging, high safety factor.

fastenal argon

fastenal argon Note that air flow was obtained from the Ar flow meter.

Not sure where you are located, but here in the US, the threads don't do any sealing. There was an error retrieving your Wish Lists. Together they amplify the sound of the gas traveling through the orifice past the main valve, resulting in whats often perceived as a hiss. BETOOLL HW9003 Argon/CO2 Mig Tig Flow meter Gas Regulator Gauge Welding Weld, RX WELD Argon/CO2 Mig Tig Flow Meter Gas Regulator Gauge With Gas Hose Welding Weld, RX WELD Argon CO2 Regulators Gauges Gas Welding Regulator CGA580 Compatible with Miller Lincoln Mig Tig Weld 0-4500PSI / 0-10BAR, Argon CO2 Regulator, Tig Mig Welding Regulator Argon Flow Meter with 6.6Ft Gas Hose CGA-580 Inlet 0-3500PSI Pressure Gauge 10-60 CFH, Industrial Argon Regulator/Flowmeter Gauges for MIG and TIG Welders - SA, Zistel CO2 Argon Regulator with Gas Hose TIG Welder. : 3.3.x, Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process. We work hard to protect your security and privacy. A basic flowmeter regulator is $35. A harmonic is defined as an integer (whole number) multiple of the fundamental frequency.

argon inert cga580 tig welder co2 argon tig regulator mig hose argon tig welder flowmeter weld regulators htp Take a Chance on Yourself: How to turn your hobby into a full-time gig! A 5/8 BSP is a .905-14 thread. This experiment should reveal the chemical differencesin the comparison of O2 and air etch rates. hbbd```b``n`d

&Hc`4 >$>@9,6H2

There are two mass flow meters in theMarch Asher. Zh (-z

=ap1jA

argon meter We use cookies on our websites for a number of purposes, including analytics and performance, functionality and advertising.

argon weld tig There are two curves in this graph, one is the etch rate as a function of airmixed with O2, and the other shows the actual pressure in the reaction chamber for each etch rate data point. I learn new stuff every day from the net. You can always double check by putting leak solution over the weep hole (the much smaller hole on the bonnet) to see if the regulator is leaking. Over time, the March Asher1 developed some air leaks which degraded the purity of Oxygen in the normal photoresist ash process. They just hold the two faces of the cone together. Learn more.

argon matweld Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them.

The decrease in clearance provides the seal in pipe threads. H1"td(i RHJtT&30u~0 7y

Pipe threads are tapered, and bind as they are threaded together. Both gases show an enhanced etch rate at low pressures where ionbombardment aids the chemical etching. 4). After viewing product detail pages, look here to find an easy way to navigate back to pages you are interested in. This is doneby adjusting the gas flows to achieve various gas compositions but maintain the same pressure.

This provides a data set that simulates a leak into the process chamber with all theresulting effects. 1), March Etcher: Leak Rate after High Power O2 Cleanup (Fig. Sorry, but the threads into the valve on the bottle, are NOT pipe threads. I had been having a lot of issues with contamination and had my tig and torch looked at by my LWS. Actually, it really is. hVmS8nw{Lp%\ADbVFI%k_N2ca@ROc?>dQ131b#Oc1^LG"#N"[cy3!Y! 4), Etch Chamber Pressure vs. Gas Flow Rate Setting (Fig. What the customer was actually experiencing was harmonic resonance. .

I got pretty good use out of the old one. If it has a very deep scratch, toss it in the trash can.

tornado flow regulator argon tube ancor meter relief valve Looks old id just replace it.

Figure 2. They are pipe threads.

argon s311 The higher pressure also causes the etch rate to decrease because ofdiminishing molecular mean free paths and subsequent reduction of sheath voltage and thus reduction of surface bombardment by high energy ions. Data was taken on the remaining thickness of photoresist by the NanoSpec thickness measurement tool to show the etch rate asa function of air content in the plasma.

argon regulator digitalweld This experiment is however convoluted becauseno control of the rising pressure due to the air content was maintained. etc. Scope of application: Housewares tools, Replacement repair tools included: Garden Tools, Hand Tools, Machine Tools ; Accessories, Measurement ; Analysis Instruments, Tool Parts, Tool Sets, Bathroom Fixture, Kitchen Fixture, Electrical Equipment ; Supplies, Home ; Garden. At first, it wasthought that the air leak was comparable to the process gas flow rate due to a missing parenthesis in the EXCEL data analysis, so an effort was made toexamine the influence of air on the O2 etch rateof photoresist. I ordered a new one already. Chemical composition of our air is unknown in detail.

The subreddit for welders, machinists and all other enthusiasts of joining two things together. Try switching to a regulator with a flow meter for tig. in case the diaphragm were to blow. This is what auser would obtain if no attention was paid to the pressure rise. March Etcher Leak Rate after Fix (Fig.

Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. In order to characterize the influence of air onthe Oxygen ash rate, I opened the Ar meter input to air so a precise amount of air could be incorporated into the plasma. TheArgon mass flow controller maximum flow is 250 sccm and the Oxygen meter is 100 sccm air flow was obtained from the Ar flow meter. - Scope of application: Housewares tools, Replacement repair tools included: Garden Tools, Hand Tools, Machine Tools ; Accessories, Measurement ; Analysis Instruments, Tool Parts, Tool Sets, Bathroom Fixture, Kitchen Fixture, Electrical Equipment ; Supplies, Home ; Garden.Specification: - Material: Copper ; Alloy - Size: Diameter 60mm/2.36inch; Height 100mm/3.94inchPackage Includes:1Piece WP-15 Small Argon Cylinder Valve Gas Bottle Regulator For Argon. To stop the noise you can either adjust the inlet pressure to a higher set point (maybe just a couple of psi) or adjust the delivery pressure up or down (again just a couple of psi) until the noise subsides. Most vibrating objects have more than one resonant frequency and those used in musical instruments typically vibrate at harmonics of the fundamental. ` n

The cleanup process consisted of a 300 W O2 plasma at a pressure of 250 mTorr for 20 minutes. The independent etch rate of both air and O2 have also been measured.

Sitemap 30

Recently, I was asked to visit a customer to troubleshoot what they thought was a leaking regulator. Vibrating strings, open cylindrical air columns and conical air columns will vibrate at all harmonics of the fundamental. 3), March RIE Air Etch Rate vs Chamber Vacuum (Fig. We do not have any recommendations at this time, Argon Cylinder Valve Manual Gas Bottle Regulator Leak- Welding Tool.

Recently, I was asked to visit a customer to troubleshoot what they thought was a leaking regulator. Vibrating strings, open cylindrical air columns and conical air columns will vibrate at all harmonics of the fundamental. 3), March RIE Air Etch Rate vs Chamber Vacuum (Fig. We do not have any recommendations at this time, Argon Cylinder Valve Manual Gas Bottle Regulator Leak- Welding Tool.  This chart calibrates the March Etcher gas flow setting to actual flow in units of Standard Cubic Centimeters per Minute (sccm). I believe that is the overpressure relief hole. Your recently viewed items and featured recommendations, Select the department you want to search in. welding weld cga580 regulator co2 argon welder tig mig meter gauge flow gas It is for this class of vibrators that the term overtone becomes usefulthey are said to have some non-harmonic overtones. 187 0 obj

<>stream

The lowest resonant frequency of a vibrating object is called its fundamental frequency. %%EOF

Figure A1. : @ VA-Sawyer - my bad - sorry for the confusion - it's weird how it's possible to be so sure in the mind yet wrong on something in reality - the reason I say it's BSP is over the years I've made various fittings to adapt cylinders or regulators & keep taps & dies in 5/8" BSP - I thought that's what I'd used - either I completely forgot & have the thread you stated or in the UK they don't use the same threads - likewise regulator outlets here are always BSP - either 1/4" or 3/8" but I assume stateside you have NPT which is kinda similar but not the same - I believe 1/2" is close enough to interchange but it gets progressively more difference on sizes either side of it - maybe some things are not quite the same across the pond - I sometimes forget that the majority of active members on the forum live in the land of the free & while we have a handful of members dotted across the globe most of the discussion centers around the states hence is more specific to your products - some things seem the same other aspects are very different between counties = I meant no offense questioning your post. I also had replaced my regular, but it didnt seem to make a difference. welder The regulators thin metal diaphragm is torqued into place between the body and bonnet of the regulator, acting much like the cone of a speaker, while the bonnet cavity acts like a speaker case. just change out with a flow meter/regulator.

This chart calibrates the March Etcher gas flow setting to actual flow in units of Standard Cubic Centimeters per Minute (sccm). I believe that is the overpressure relief hole. Your recently viewed items and featured recommendations, Select the department you want to search in. welding weld cga580 regulator co2 argon welder tig mig meter gauge flow gas It is for this class of vibrators that the term overtone becomes usefulthey are said to have some non-harmonic overtones. 187 0 obj

<>stream

The lowest resonant frequency of a vibrating object is called its fundamental frequency. %%EOF

Figure A1. : @ VA-Sawyer - my bad - sorry for the confusion - it's weird how it's possible to be so sure in the mind yet wrong on something in reality - the reason I say it's BSP is over the years I've made various fittings to adapt cylinders or regulators & keep taps & dies in 5/8" BSP - I thought that's what I'd used - either I completely forgot & have the thread you stated or in the UK they don't use the same threads - likewise regulator outlets here are always BSP - either 1/4" or 3/8" but I assume stateside you have NPT which is kinda similar but not the same - I believe 1/2" is close enough to interchange but it gets progressively more difference on sizes either side of it - maybe some things are not quite the same across the pond - I sometimes forget that the majority of active members on the forum live in the land of the free & while we have a handful of members dotted across the globe most of the discussion centers around the states hence is more specific to your products - some things seem the same other aspects are very different between counties = I meant no offense questioning your post. I also had replaced my regular, but it didnt seem to make a difference. welder The regulators thin metal diaphragm is torqued into place between the body and bonnet of the regulator, acting much like the cone of a speaker, while the bonnet cavity acts like a speaker case. just change out with a flow meter/regulator.

Learn more about Reddits use of cookies. Please try again. 171 0 obj

<>/Filter/FlateDecode/ID[<9BCA822C47394E2384C16AE6C1834071><085D8F6CDAC62C45838C7042BB6A6493>]/Index[143 45]/Info 142 0 R/Length 128/Prev 1248679/Root 144 0 R/Size 188/Type/XRef/W[1 3 1]>>stream

I ordered a new one. The diaphragm is bad/cracked and leaking. Harmonic resonance sometimes occurs in metal diaphragm pressure regulators with the combination of (in this case) low inlet pressure 100 psig and low outlet pressure 60 psig (can also be high inlet pressure, very low outlet pressure and a low-density gas). This item can be returned in its original condition for a full refund or replacement within 30 days of receipt. 1), March Etcher RIE Etch Rate of s1813 Photoresist vs %Air in O2 (Fig. Ok cool. ?p1`c.x,cg40Q7g

Learn more about Reddits use of cookies. Please try again. 171 0 obj

<>/Filter/FlateDecode/ID[<9BCA822C47394E2384C16AE6C1834071><085D8F6CDAC62C45838C7042BB6A6493>]/Index[143 45]/Info 142 0 R/Length 128/Prev 1248679/Root 144 0 R/Size 188/Type/XRef/W[1 3 1]>>stream

I ordered a new one. The diaphragm is bad/cracked and leaking. Harmonic resonance sometimes occurs in metal diaphragm pressure regulators with the combination of (in this case) low inlet pressure 100 psig and low outlet pressure 60 psig (can also be high inlet pressure, very low outlet pressure and a low-density gas). This item can be returned in its original condition for a full refund or replacement within 30 days of receipt. 1), March Etcher RIE Etch Rate of s1813 Photoresist vs %Air in O2 (Fig. Ok cool. ?p1`c.x,cg40Q7g  To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. As time goes on,the base pump pressure may degrade and shift the lower end of this correlation curve somewhat. Thisexperiment will show us the etch rates of both air and O2 as a function of chamber pressure. A1 & A2). ar co2 welding argon meter flow welder lotos technology welderguide regulator argon gauge co2 tig This gives us a value on which to improve by finding and fixing the air leaks into the chamber.

To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. As time goes on,the base pump pressure may degrade and shift the lower end of this correlation curve somewhat. Thisexperiment will show us the etch rates of both air and O2 as a function of chamber pressure. A1 & A2). ar co2 welding argon meter flow welder lotos technology welderguide regulator argon gauge co2 tig This gives us a value on which to improve by finding and fixing the air leaks into the chamber.  The Welders Lens Offers a Free Home Study Course. Figure 3. There was a problem adding this item to Cart. Enhancements you chose aren't available for this seller. Fast forward to today I need to do some welding, contamination be damned, and now my regular is leaking. 2), March RIE Oxygen Etch Rate vs Chamber Vacuum (Fig. We use cookies to improve your browsing experience and help us improve our websites. , Manufacturer Applicable medium: argon; working pressure (mpa); Model: WP-15. The Argon Mass Flow Controller maximum flow is 250 sccm, and the Oxygen MFC meter is 100 sccm thus the large difference in pressurecurves. hb```f``j``e`8 ,l@Cq3=Xy\Sv?\^!sUE:3Hdug]3.m|I{yGGG; 2t0 IK+@Z If the regulator is leaking, the pressure on the gauge(s) will drop from the set point to zero. Vibrating membranes typically produce vibrations at harmonics, but also have some resonant frequencies which are not harmonics. Constant pressure photoresist etch rate as a function of air to O2 ratio.

The Welders Lens Offers a Free Home Study Course. Figure 3. There was a problem adding this item to Cart. Enhancements you chose aren't available for this seller. Fast forward to today I need to do some welding, contamination be damned, and now my regular is leaking. 2), March RIE Oxygen Etch Rate vs Chamber Vacuum (Fig. We use cookies to improve your browsing experience and help us improve our websites. , Manufacturer Applicable medium: argon; working pressure (mpa); Model: WP-15. The Argon Mass Flow Controller maximum flow is 250 sccm, and the Oxygen MFC meter is 100 sccm thus the large difference in pressurecurves. hb```f``j``e`8 ,l@Cq3=Xy\Sv?\^!sUE:3Hdug]3.m|I{yGGG; 2t0 IK+@Z If the regulator is leaking, the pressure on the gauge(s) will drop from the set point to zero. Vibrating membranes typically produce vibrations at harmonics, but also have some resonant frequencies which are not harmonics. Constant pressure photoresist etch rate as a function of air to O2 ratio.  By continuing to use our website, you agree to our use of such cookies. - Selected materials, for safety , to prevent air leakage, use preferred copper forging, high safety factor. This cause the elastomer material in the diaphragm to harden and crack.

By continuing to use our website, you agree to our use of such cookies. - Selected materials, for safety , to prevent air leakage, use preferred copper forging, high safety factor. This cause the elastomer material in the diaphragm to harden and crack.

The conclusion is that amazingly enough, the plasma composition does not change theetch rate appreciably over the entire range of compositions. Cylinders with one end closed will vibrate with only odd harmonics of the fundamental. Thispaper focuses on the gas composition, so all variables are held constant except gas composition and pressure.

The conclusion is that amazingly enough, the plasma composition does not change theetch rate appreciably over the entire range of compositions. Cylinders with one end closed will vibrate with only odd harmonics of the fundamental. Thispaper focuses on the gas composition, so all variables are held constant except gas composition and pressure.  Reviewed in the United States on August 1, 2021.

Reviewed in the United States on August 1, 2021.  The threads are supposed to seal. Happens in older regulators due to gradual exposure to ozone pollution over time.

The threads are supposed to seal. Happens in older regulators due to gradual exposure to ozone pollution over time.  Figure 4 shows the results. To accomplish this goal, a 3 inch diameter wafer was coated with Shipley 1813 photoresist and subjected to 5 minute etches atvarious flow rates of air.

Figure 4 shows the results. To accomplish this goal, a 3 inch diameter wafer was coated with Shipley 1813 photoresist and subjected to 5 minute etches atvarious flow rates of air.  I believe your diaphragm is leaking. 0

3 to that in Fig. U^MKez\]37 I9.FVk F'SCo9onY-+u=oS8,[_k};[!5[Ox'NH 9b&g/:9lyCEYlf}Hp{S',4)l&Mq0T+cz57|y;U**Cxv'tyibEC%

UF%c dG:1f+1+4f TJTM"x49DO@'v The customer brought me to the location where the regulator is installed and was providing gas to the application.

I believe your diaphragm is leaking. 0

3 to that in Fig. U^MKez\]37 I9.FVk F'SCo9onY-+u=oS8,[_k};[!5[Ox'NH 9b&g/:9lyCEYlf}Hp{S',4)l&Mq0T+cz57|y;U**Cxv'tyibEC%

UF%c dG:1f+1+4f TJTM"x49DO@'v The customer brought me to the location where the regulator is installed and was providing gas to the application.  You need to have a pretty good BS filter, but there is a lot of good infomation available. If the regulator has a needle valve, adjusting the valve can also assist in eliminating or reducing the resonance. - Self-contained safety valve, high sensitivity, , explosion-proof, anti-explosion tube, anti-heading, anti-fee. Your email address will not be published. In the case of my customer, the harmonic resonance concerned him and he wanted to make it stop. The seal is the two metal faces, sometimes with an Oring on the Male side. The Oxygen flow meter has a 100 sccm max, and the Argon flow meter has a 250 sccm max. Will rebuild it. This was manipulated to maintain a constant pressure in one experiment and allowed to add pressure in another tosimulate a true leak. Selected materials, for safety , to prevent air leakage, use preferred copper forging, high safety factor.

You need to have a pretty good BS filter, but there is a lot of good infomation available. If the regulator has a needle valve, adjusting the valve can also assist in eliminating or reducing the resonance. - Self-contained safety valve, high sensitivity, , explosion-proof, anti-explosion tube, anti-heading, anti-fee. Your email address will not be published. In the case of my customer, the harmonic resonance concerned him and he wanted to make it stop. The seal is the two metal faces, sometimes with an Oring on the Male side. The Oxygen flow meter has a 100 sccm max, and the Argon flow meter has a 250 sccm max. Will rebuild it. This was manipulated to maintain a constant pressure in one experiment and allowed to add pressure in another tosimulate a true leak. Selected materials, for safety , to prevent air leakage, use preferred copper forging, high safety factor.  fastenal argon Note that air flow was obtained from the Ar flow meter. Not sure where you are located, but here in the US, the threads don't do any sealing. There was an error retrieving your Wish Lists. Together they amplify the sound of the gas traveling through the orifice past the main valve, resulting in whats often perceived as a hiss. BETOOLL HW9003 Argon/CO2 Mig Tig Flow meter Gas Regulator Gauge Welding Weld, RX WELD Argon/CO2 Mig Tig Flow Meter Gas Regulator Gauge With Gas Hose Welding Weld, RX WELD Argon CO2 Regulators Gauges Gas Welding Regulator CGA580 Compatible with Miller Lincoln Mig Tig Weld 0-4500PSI / 0-10BAR, Argon CO2 Regulator, Tig Mig Welding Regulator Argon Flow Meter with 6.6Ft Gas Hose CGA-580 Inlet 0-3500PSI Pressure Gauge 10-60 CFH, Industrial Argon Regulator/Flowmeter Gauges for MIG and TIG Welders - SA, Zistel CO2 Argon Regulator with Gas Hose TIG Welder. : 3.3.x, Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process. We work hard to protect your security and privacy. A basic flowmeter regulator is $35. A harmonic is defined as an integer (whole number) multiple of the fundamental frequency. argon inert cga580 tig welder co2 argon tig regulator mig hose argon tig welder flowmeter weld regulators htp Take a Chance on Yourself: How to turn your hobby into a full-time gig! A 5/8 BSP is a .905-14 thread. This experiment should reveal the chemical differencesin the comparison of O2 and air etch rates. hbbd```b``n`d

&Hc`4 >$>@9,6H2

fastenal argon Note that air flow was obtained from the Ar flow meter. Not sure where you are located, but here in the US, the threads don't do any sealing. There was an error retrieving your Wish Lists. Together they amplify the sound of the gas traveling through the orifice past the main valve, resulting in whats often perceived as a hiss. BETOOLL HW9003 Argon/CO2 Mig Tig Flow meter Gas Regulator Gauge Welding Weld, RX WELD Argon/CO2 Mig Tig Flow Meter Gas Regulator Gauge With Gas Hose Welding Weld, RX WELD Argon CO2 Regulators Gauges Gas Welding Regulator CGA580 Compatible with Miller Lincoln Mig Tig Weld 0-4500PSI / 0-10BAR, Argon CO2 Regulator, Tig Mig Welding Regulator Argon Flow Meter with 6.6Ft Gas Hose CGA-580 Inlet 0-3500PSI Pressure Gauge 10-60 CFH, Industrial Argon Regulator/Flowmeter Gauges for MIG and TIG Welders - SA, Zistel CO2 Argon Regulator with Gas Hose TIG Welder. : 3.3.x, Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process. We work hard to protect your security and privacy. A basic flowmeter regulator is $35. A harmonic is defined as an integer (whole number) multiple of the fundamental frequency. argon inert cga580 tig welder co2 argon tig regulator mig hose argon tig welder flowmeter weld regulators htp Take a Chance on Yourself: How to turn your hobby into a full-time gig! A 5/8 BSP is a .905-14 thread. This experiment should reveal the chemical differencesin the comparison of O2 and air etch rates. hbbd```b``n`d

&Hc`4 >$>@9,6H2  There are two mass flow meters in theMarch Asher. Zh (-z

=ap1jA argon meter We use cookies on our websites for a number of purposes, including analytics and performance, functionality and advertising. argon weld tig There are two curves in this graph, one is the etch rate as a function of airmixed with O2, and the other shows the actual pressure in the reaction chamber for each etch rate data point. I learn new stuff every day from the net. You can always double check by putting leak solution over the weep hole (the much smaller hole on the bonnet) to see if the regulator is leaking. Over time, the March Asher1 developed some air leaks which degraded the purity of Oxygen in the normal photoresist ash process. They just hold the two faces of the cone together. Learn more. argon matweld Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them.

There are two mass flow meters in theMarch Asher. Zh (-z

=ap1jA argon meter We use cookies on our websites for a number of purposes, including analytics and performance, functionality and advertising. argon weld tig There are two curves in this graph, one is the etch rate as a function of airmixed with O2, and the other shows the actual pressure in the reaction chamber for each etch rate data point. I learn new stuff every day from the net. You can always double check by putting leak solution over the weep hole (the much smaller hole on the bonnet) to see if the regulator is leaking. Over time, the March Asher1 developed some air leaks which degraded the purity of Oxygen in the normal photoresist ash process. They just hold the two faces of the cone together. Learn more. argon matweld Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them.

The decrease in clearance provides the seal in pipe threads. H1"td(i RHJtT&30u~0 7y

Pipe threads are tapered, and bind as they are threaded together. Both gases show an enhanced etch rate at low pressures where ionbombardment aids the chemical etching. 4). After viewing product detail pages, look here to find an easy way to navigate back to pages you are interested in. This is doneby adjusting the gas flows to achieve various gas compositions but maintain the same pressure.

The decrease in clearance provides the seal in pipe threads. H1"td(i RHJtT&30u~0 7y

Pipe threads are tapered, and bind as they are threaded together. Both gases show an enhanced etch rate at low pressures where ionbombardment aids the chemical etching. 4). After viewing product detail pages, look here to find an easy way to navigate back to pages you are interested in. This is doneby adjusting the gas flows to achieve various gas compositions but maintain the same pressure.  This provides a data set that simulates a leak into the process chamber with all theresulting effects. 1), March Etcher: Leak Rate after High Power O2 Cleanup (Fig. Sorry, but the threads into the valve on the bottle, are NOT pipe threads. I had been having a lot of issues with contamination and had my tig and torch looked at by my LWS. Actually, it really is. hVmS8nw{Lp%\ADbVFI%k_N2ca@ROc?>dQ131b#Oc1^LG"#N"[cy3!Y! 4), Etch Chamber Pressure vs. Gas Flow Rate Setting (Fig. What the customer was actually experiencing was harmonic resonance. . I got pretty good use out of the old one. If it has a very deep scratch, toss it in the trash can. tornado flow regulator argon tube ancor meter relief valve Looks old id just replace it. Figure 2. They are pipe threads. argon s311 The higher pressure also causes the etch rate to decrease because ofdiminishing molecular mean free paths and subsequent reduction of sheath voltage and thus reduction of surface bombardment by high energy ions. Data was taken on the remaining thickness of photoresist by the NanoSpec thickness measurement tool to show the etch rate asa function of air content in the plasma. argon regulator digitalweld This experiment is however convoluted becauseno control of the rising pressure due to the air content was maintained. etc. Scope of application: Housewares tools, Replacement repair tools included: Garden Tools, Hand Tools, Machine Tools ; Accessories, Measurement ; Analysis Instruments, Tool Parts, Tool Sets, Bathroom Fixture, Kitchen Fixture, Electrical Equipment ; Supplies, Home ; Garden. At first, it wasthought that the air leak was comparable to the process gas flow rate due to a missing parenthesis in the EXCEL data analysis, so an effort was made toexamine the influence of air on the O2 etch rateof photoresist. I ordered a new one already. Chemical composition of our air is unknown in detail.

This provides a data set that simulates a leak into the process chamber with all theresulting effects. 1), March Etcher: Leak Rate after High Power O2 Cleanup (Fig. Sorry, but the threads into the valve on the bottle, are NOT pipe threads. I had been having a lot of issues with contamination and had my tig and torch looked at by my LWS. Actually, it really is. hVmS8nw{Lp%\ADbVFI%k_N2ca@ROc?>dQ131b#Oc1^LG"#N"[cy3!Y! 4), Etch Chamber Pressure vs. Gas Flow Rate Setting (Fig. What the customer was actually experiencing was harmonic resonance. . I got pretty good use out of the old one. If it has a very deep scratch, toss it in the trash can. tornado flow regulator argon tube ancor meter relief valve Looks old id just replace it. Figure 2. They are pipe threads. argon s311 The higher pressure also causes the etch rate to decrease because ofdiminishing molecular mean free paths and subsequent reduction of sheath voltage and thus reduction of surface bombardment by high energy ions. Data was taken on the remaining thickness of photoresist by the NanoSpec thickness measurement tool to show the etch rate asa function of air content in the plasma. argon regulator digitalweld This experiment is however convoluted becauseno control of the rising pressure due to the air content was maintained. etc. Scope of application: Housewares tools, Replacement repair tools included: Garden Tools, Hand Tools, Machine Tools ; Accessories, Measurement ; Analysis Instruments, Tool Parts, Tool Sets, Bathroom Fixture, Kitchen Fixture, Electrical Equipment ; Supplies, Home ; Garden. At first, it wasthought that the air leak was comparable to the process gas flow rate due to a missing parenthesis in the EXCEL data analysis, so an effort was made toexamine the influence of air on the O2 etch rateof photoresist. I ordered a new one already. Chemical composition of our air is unknown in detail.  Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. In order to characterize the influence of air onthe Oxygen ash rate, I opened the Ar meter input to air so a precise amount of air could be incorporated into the plasma. TheArgon mass flow controller maximum flow is 250 sccm and the Oxygen meter is 100 sccm air flow was obtained from the Ar flow meter. - Scope of application: Housewares tools, Replacement repair tools included: Garden Tools, Hand Tools, Machine Tools ; Accessories, Measurement ; Analysis Instruments, Tool Parts, Tool Sets, Bathroom Fixture, Kitchen Fixture, Electrical Equipment ; Supplies, Home ; Garden.Specification: - Material: Copper ; Alloy - Size: Diameter 60mm/2.36inch; Height 100mm/3.94inchPackage Includes:1Piece WP-15 Small Argon Cylinder Valve Gas Bottle Regulator For Argon. To stop the noise you can either adjust the inlet pressure to a higher set point (maybe just a couple of psi) or adjust the delivery pressure up or down (again just a couple of psi) until the noise subsides. Most vibrating objects have more than one resonant frequency and those used in musical instruments typically vibrate at harmonics of the fundamental. ` n

The cleanup process consisted of a 300 W O2 plasma at a pressure of 250 mTorr for 20 minutes. The independent etch rate of both air and O2 have also been measured.

Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. In order to characterize the influence of air onthe Oxygen ash rate, I opened the Ar meter input to air so a precise amount of air could be incorporated into the plasma. TheArgon mass flow controller maximum flow is 250 sccm and the Oxygen meter is 100 sccm air flow was obtained from the Ar flow meter. - Scope of application: Housewares tools, Replacement repair tools included: Garden Tools, Hand Tools, Machine Tools ; Accessories, Measurement ; Analysis Instruments, Tool Parts, Tool Sets, Bathroom Fixture, Kitchen Fixture, Electrical Equipment ; Supplies, Home ; Garden.Specification: - Material: Copper ; Alloy - Size: Diameter 60mm/2.36inch; Height 100mm/3.94inchPackage Includes:1Piece WP-15 Small Argon Cylinder Valve Gas Bottle Regulator For Argon. To stop the noise you can either adjust the inlet pressure to a higher set point (maybe just a couple of psi) or adjust the delivery pressure up or down (again just a couple of psi) until the noise subsides. Most vibrating objects have more than one resonant frequency and those used in musical instruments typically vibrate at harmonics of the fundamental. ` n

The cleanup process consisted of a 300 W O2 plasma at a pressure of 250 mTorr for 20 minutes. The independent etch rate of both air and O2 have also been measured.