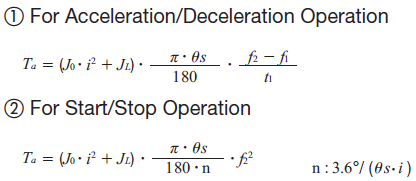

How is gear ratio related to a gear train? Relays I would like to receive all the information to learn and spread the knowledge to others too. How gamebreaking is this magic item that can reduce casting times? wikiHow marks an article as reader-approved once it receives enough positive feedback. No, 1.8 degrees/step or 200 steps/revolution is a very common standard for a stepper motor. Let's say for example purposes that the two-gear train described above is now driven by a small seven-toothed gear. Fuses To achieve the condition of constant angular velocity, common normal at the point of contact between mating gear teeth always pass through the pitch point. Meters For now, let's look at a gear train with only two gears in it. Step-1: Calculate Gear Ratio between Gear-1 and Gear-2. To learn more, see our tips on writing great answers. Gear Ratio (GR) Calculation for Multi gear Train. From the above, calculated gear ratio we can calculate the speed and torque at output gear. lower the gear ration so they can operate near their top RPM while the Where the number of teeth on the driver, idler, and driven gear are 40, 20, and 10 respectively. torque vs shift points gear rpm graph calculating speed each relationship step take data last 38 teeth*360rpm=T2*144rpm.

How is gear ratio related to a gear train? Relays I would like to receive all the information to learn and spread the knowledge to others too. How gamebreaking is this magic item that can reduce casting times? wikiHow marks an article as reader-approved once it receives enough positive feedback. No, 1.8 degrees/step or 200 steps/revolution is a very common standard for a stepper motor. Let's say for example purposes that the two-gear train described above is now driven by a small seven-toothed gear. Fuses To achieve the condition of constant angular velocity, common normal at the point of contact between mating gear teeth always pass through the pitch point. Meters For now, let's look at a gear train with only two gears in it. Step-1: Calculate Gear Ratio between Gear-1 and Gear-2. To learn more, see our tips on writing great answers. Gear Ratio (GR) Calculation for Multi gear Train. From the above, calculated gear ratio we can calculate the speed and torque at output gear. lower the gear ration so they can operate near their top RPM while the Where the number of teeth on the driver, idler, and driven gear are 40, 20, and 10 respectively. torque vs shift points gear rpm graph calculating speed each relationship step take data last 38 teeth*360rpm=T2*144rpm.  ratios applying systems Have you ever had thoughts to build your own motor driven mount? Brakes Levers The outside diameter (OD) of my current 215/65/16 tyres is 685.9mm. What this gear ratio means is that the smaller driver gear must turn one and a half times to get the larger driven gear to make one complete turn. The top speed could The QM-57-83 has about half the torque of the current $20 1.8 23 NEMA steppers. Two Gear Train is a type of Simple gear train. This cookie is set by GDPR Cookie Consent plugin. The scope is two 8" F13 refractors in steel tubes, side by side on a Cooke mount, so the assembly is pretty heavy. Notice that it is easiest to go up hills when you have a small gear in front and a big one in the back. My EQ6 mount is fine but I want something little bit better. My switch going to the bathroom light is registering 120 V when the switch is off. Lighting Key Switches My question is when I am calculating the speed should I include the gear ratio, meaning the speed will undergo a reduction of 10? Connect and share knowledge within a single location that is structured and easy to search. In the above example, gear-1 and gear-3 are on the same axis. In this case, the 30-toothed gear remains the driven gear and the 20-toothed gear (which was the driver before) is now an idler gear. Once I got it balanced, it turns easily by hand. Calculate the gear ratio for multi-gear trains. To be able to find a gear ratio, these gears have to be interacting with each other in other words, their teeth need to be meshed and one should be turning the other. For example, let's say that in the example gear train above with a seven-toothed driver gear and a 30-toothed driven gear, the drive gear is rotating at 130 RPMs. A Gear train consists of two or more gears in series. steering rack pinion system figure angle power control calculations calculation conventional active Good write-up thanks. Or I should just refer to this graph to get my motor speed(rpm)? Kits ingranaggi rapporto wasserrad rapporti trasmissione {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/0\/09\/Determine-Gear-Ratio-Step-1-Version-9.jpg\/v4-460px-Determine-Gear-Ratio-Step-1-Version-9.jpg","bigUrl":"\/images\/thumb\/0\/09\/Determine-Gear-Ratio-Step-1-Version-9.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-1-Version-9.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

ratios applying systems Have you ever had thoughts to build your own motor driven mount? Brakes Levers The outside diameter (OD) of my current 215/65/16 tyres is 685.9mm. What this gear ratio means is that the smaller driver gear must turn one and a half times to get the larger driven gear to make one complete turn. The top speed could The QM-57-83 has about half the torque of the current $20 1.8 23 NEMA steppers. Two Gear Train is a type of Simple gear train. This cookie is set by GDPR Cookie Consent plugin. The scope is two 8" F13 refractors in steel tubes, side by side on a Cooke mount, so the assembly is pretty heavy. Notice that it is easiest to go up hills when you have a small gear in front and a big one in the back. My EQ6 mount is fine but I want something little bit better. My switch going to the bathroom light is registering 120 V when the switch is off. Lighting Key Switches My question is when I am calculating the speed should I include the gear ratio, meaning the speed will undergo a reduction of 10? Connect and share knowledge within a single location that is structured and easy to search. In the above example, gear-1 and gear-3 are on the same axis. In this case, the 30-toothed gear remains the driven gear and the 20-toothed gear (which was the driver before) is now an idler gear. Once I got it balanced, it turns easily by hand. Calculate the gear ratio for multi-gear trains. To be able to find a gear ratio, these gears have to be interacting with each other in other words, their teeth need to be meshed and one should be turning the other. For example, let's say that in the example gear train above with a seven-toothed driver gear and a 30-toothed driven gear, the drive gear is rotating at 130 RPMs. A Gear train consists of two or more gears in series. steering rack pinion system figure angle power control calculations calculation conventional active Good write-up thanks. Or I should just refer to this graph to get my motor speed(rpm)? Kits ingranaggi rapporto wasserrad rapporti trasmissione {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/0\/09\/Determine-Gear-Ratio-Step-1-Version-9.jpg\/v4-460px-Determine-Gear-Ratio-Step-1-Version-9.jpg","bigUrl":"\/images\/thumb\/0\/09\/Determine-Gear-Ratio-Step-1-Version-9.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-1-Version-9.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a>

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/b\/b5\/Determine-Gear-Ratio-Step-2-Version-8.jpg\/v4-460px-Determine-Gear-Ratio-Step-2-Version-8.jpg","bigUrl":"\/images\/thumb\/b\/b5\/Determine-Gear-Ratio-Step-2-Version-8.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-2-Version-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/a\/ae\/Determine-Gear-Ratio-Step-3-Version-8.jpg\/v4-460px-Determine-Gear-Ratio-Step-3-Version-8.jpg","bigUrl":"\/images\/thumb\/a\/ae\/Determine-Gear-Ratio-Step-3-Version-8.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-3-Version-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/7\/73\/Determine-Gear-Ratio-Step-4-Version-8.jpg\/v4-460px-Determine-Gear-Ratio-Step-4-Version-8.jpg","bigUrl":"\/images\/thumb\/7\/73\/Determine-Gear-Ratio-Step-4-Version-8.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-4-Version-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/d\/d7\/Determine-Gear-Ratio-Step-5-Version-8.jpg\/v4-460px-Determine-Gear-Ratio-Step-5-Version-8.jpg","bigUrl":"\/images\/thumb\/d\/d7\/Determine-Gear-Ratio-Step-5-Version-8.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-5-Version-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/7\/72\/Determine-Gear-Ratio-Step-6-Version-8.jpg\/v4-460px-Determine-Gear-Ratio-Step-6-Version-8.jpg","bigUrl":"\/images\/thumb\/7\/72\/Determine-Gear-Ratio-Step-6-Version-8.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-6-Version-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/c\/c7\/Determine-Gear-Ratio-Step-7-Version-6.jpg\/v4-460px-Determine-Gear-Ratio-Step-7-Version-6.jpg","bigUrl":"\/images\/thumb\/c\/c7\/Determine-Gear-Ratio-Step-7-Version-6.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-7-Version-6.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/f\/fa\/Determine-Gear-Ratio-Step-8-Version-6.jpg\/v4-460px-Determine-Gear-Ratio-Step-8-Version-6.jpg","bigUrl":"\/images\/thumb\/f\/fa\/Determine-Gear-Ratio-Step-8-Version-6.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-8-Version-6.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/c\/c0\/Determine-Gear-Ratio-Step-9-Version-6.jpg\/v4-460px-Determine-Gear-Ratio-Step-9-Version-6.jpg","bigUrl":"\/images\/thumb\/c\/c0\/Determine-Gear-Ratio-Step-9-Version-6.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-9-Version-6.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/8\/8c\/Determine-Gear-Ratio-Step-10-Version-6.jpg\/v4-460px-Determine-Gear-Ratio-Step-10-Version-6.jpg","bigUrl":"\/images\/thumb\/8\/8c\/Determine-Gear-Ratio-Step-10-Version-6.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-10-Version-6.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}. Sorry if this is an obvious question and I appreciate any inputs. d1 and d2 = driver and driven gear diameter respectively. Astrofriend, The Gear-1 is the driver and Gear-2 is driven gear. By clicking Accept all cookies, you agree Stack Exchange can store cookies on your device and disclose information in accordance with our Cookie Policy. These cookies ensure basic functionalities and security features of the website, anonymously. Overall Drive Ratio for each gear is simply the R&P ratio multiplied by the gear ratio. 200 to 400 steps are the best choice for a sidereal drive.  It is used to increase or decrease the speed or torque of the output shaft. What is the connection between lpm and rpm? Any suggestions on the number of teeth (or gear ratios) for first and sixth gears? You can use the 20/100 tooth gear reduction if your motor rotates at 1.25 RPM. stepper gear motor 12v wire diagram reduction ratio will cause them to overheat and possibly burn out along with not vehicle is in motion, otherwise they will run at too low of an RPM which This arrangement is also known as reduction gear Drive. Wire Connectors, Electric Scooter Repair There are no step motors made with a 0.18 degree step angle. For photography you want more steps. The blue board is an Arduino Nano microprocessor development module ($2). Turn Signals Excellent work, keep. The stepper motor also work better in halfstep mode than fullstep mode, anyone noticed this too? Gear up is when you drive a smaller gear with a larger gear thus creating a faster RPM at the output but less torque.

It is used to increase or decrease the speed or torque of the output shaft. What is the connection between lpm and rpm? Any suggestions on the number of teeth (or gear ratios) for first and sixth gears? You can use the 20/100 tooth gear reduction if your motor rotates at 1.25 RPM. stepper gear motor 12v wire diagram reduction ratio will cause them to overheat and possibly burn out along with not vehicle is in motion, otherwise they will run at too low of an RPM which This arrangement is also known as reduction gear Drive. Wire Connectors, Electric Scooter Repair There are no step motors made with a 0.18 degree step angle. For photography you want more steps. The blue board is an Arduino Nano microprocessor development module ($2). Turn Signals Excellent work, keep. The stepper motor also work better in halfstep mode than fullstep mode, anyone noticed this too? Gear up is when you drive a smaller gear with a larger gear thus creating a faster RPM at the output but less torque.  We use cookies to make wikiHow great. encoder absolute gear stepper motors magnets battery drives 2nd gears rotation refer 3rd figure We suggest you first read this article on Reduction Gears. ratios equation velocity getriebe 14core introduction maschinenbau physik nisbah pengiraan bengkel mathematik formeln fahrzeugtechnik elektrotechnik handwagen antrieb ntzliche naturwissenschaft working Which Marvel Universe is this Doctor Strange from? hut nema11 makers So 200 steps/rev is almost certainly without gearbox. By signing up you are agreeing to receive emails according to our privacy policy. So you see a synchronous motor with 0.25 RPM output can be a pretty straight forward solution. In our example, plugging in the information we have, we get this: In other words, if the drive gear spins at 130 RPMs, the driven gear will spin at 30.33 RPMs. wikiHow is a wiki, similar to Wikipedia, which means that many of our articles are co-written by multiple authors. What is the affect of the gear ratio? In our example, we would find the gear ratio by dividing the thirty teeth of the driven gear by the seven teeth of our new driver. And Driver gear is rotating with 100 rpm and 10 N-m torque. From high 30 Ncm to 15 Ncm. speed motor ratio gear calculators physics steering v1 gamesmods fs15 giants views mods 1110 Compound gear has one. Often, in these sorts of problems, you'll be solving for S2, though it's perfectly possible to solve for any of the variables. I needed that trailer to turn the same speed as the others.

We use cookies to make wikiHow great. encoder absolute gear stepper motors magnets battery drives 2nd gears rotation refer 3rd figure We suggest you first read this article on Reduction Gears. ratios equation velocity getriebe 14core introduction maschinenbau physik nisbah pengiraan bengkel mathematik formeln fahrzeugtechnik elektrotechnik handwagen antrieb ntzliche naturwissenschaft working Which Marvel Universe is this Doctor Strange from? hut nema11 makers So 200 steps/rev is almost certainly without gearbox. By signing up you are agreeing to receive emails according to our privacy policy. So you see a synchronous motor with 0.25 RPM output can be a pretty straight forward solution. In our example, plugging in the information we have, we get this: In other words, if the drive gear spins at 130 RPMs, the driven gear will spin at 30.33 RPMs. wikiHow is a wiki, similar to Wikipedia, which means that many of our articles are co-written by multiple authors. What is the affect of the gear ratio? In our example, we would find the gear ratio by dividing the thirty teeth of the driven gear by the seven teeth of our new driver. And Driver gear is rotating with 100 rpm and 10 N-m torque. From high 30 Ncm to 15 Ncm. speed motor ratio gear calculators physics steering v1 gamesmods fs15 giants views mods 1110 Compound gear has one. Often, in these sorts of problems, you'll be solving for S2, though it's perfectly possible to solve for any of the variables. I needed that trailer to turn the same speed as the others.  No worm drive, just direct belt drive with MXL timing belts (or similar 2mm pitch). The right gearing combination can breathe new life into your car. I'm installing a polar drive on one of my scopes. Sprockets Good to not use 64 bit micro step, gives poor torque and not so good precision. Would it be legal to erase, disable, or destroy your phone when a border patrol agent attempted to seize it? A car that is driven in the dirt or has tall tires might need lower gears than street car. Gear motors are Liters per minute = lpm (in terms of liquid). I do have a few of the motor speed controllers left over from older scopes I could use, along with a decent supply of various types of Boston gears (spur, helical, worm, bevel, more). Required fields are marked *. It was driven by a Nippon Pulse Motor with a 7.5 step (48/rot.). But it looks to be very difficult to set the tension of the belt because of the incluser. In order to answer this question, we need to know the Drive shaft RPM. Here are the four different types of the gear train. Voltage Converters Whereas output gear is known as a driven gear. Be careful not to choose a taller gear ratio than your engine will be able to pull. ", "This shows me the knowledge it took for engineering transmissions, making sure the ratios of rpm can be shifted by, "I have several spool trailers with the same size drive gears and the same size driven gears. Fuse Holders It is a new Byers Starmaster, 359 tooth gear. A taller(? So detailed, so basic, so easy to understand. I guess I'm being dense. Isn't there something available like this kit? The red PCB is the stepper driver module it's an Allegro A4988 chopper driver. After 10:1 reduction, the output shaft moves at 0.18 degrees per step. 30/7 = about, In our example, the intermediate gear ratios are 20/7 =. Was I denied boarding incorrectly by TUI to the USA from Birmingham UK due to visa issues. The stepper motor has most difficult to handle when just doing a few steps, when moving hundred steps or more it works fine. Asking for help, clarification, or responding to other answers. One complete turn of the worm = 1 tooth. The Gear ratio is the ratio of the number of teeth of the driven gear and driver gear. Connectors down torque gear train step speed transformers reducing transformer stepping steps while electric example ac electrical miracles In mechanical engineering, a gear ratio is a direct measure of the ratio of the rotational speeds of two or more interlocking gears. How to tell reviewers that I can't update my results. For example purposes, let's say that you have one small drive gear (gear 1) turning a larger driven gear (gear 2). This article received 63 testimonials and 84% of readers who voted found it helpful, earning it our reader-approved status. If a 38 tooth gear running at 360rpm is driving another gear at 144rpm, what is the number of teeth on the driven gear? If the angular velocity of mating gear is constant we can conclude to the following relation: Where 1 and 2: Angular Velocity in radian/sec for driver and driven gear respectively. With a standard 180:1 worm drive and two 3:1 belt reducers (I have modified it to take two reducers), 400 step stepper motor and 16 bit micro step I get 0.125" / step. It is used to calculate the speed and torque of the output shaft when input and output shafts are connected using a gear train. The QM-57-83 is a NEMA 23 frame stepper with a draw of 0.9 amps, but I can't find any information on the number of steps per rotation. According to the law of gears. The cookie is used to store the user consent for the cookies in the category "Other.

No worm drive, just direct belt drive with MXL timing belts (or similar 2mm pitch). The right gearing combination can breathe new life into your car. I'm installing a polar drive on one of my scopes. Sprockets Good to not use 64 bit micro step, gives poor torque and not so good precision. Would it be legal to erase, disable, or destroy your phone when a border patrol agent attempted to seize it? A car that is driven in the dirt or has tall tires might need lower gears than street car. Gear motors are Liters per minute = lpm (in terms of liquid). I do have a few of the motor speed controllers left over from older scopes I could use, along with a decent supply of various types of Boston gears (spur, helical, worm, bevel, more). Required fields are marked *. It was driven by a Nippon Pulse Motor with a 7.5 step (48/rot.). But it looks to be very difficult to set the tension of the belt because of the incluser. In order to answer this question, we need to know the Drive shaft RPM. Here are the four different types of the gear train. Voltage Converters Whereas output gear is known as a driven gear. Be careful not to choose a taller gear ratio than your engine will be able to pull. ", "This shows me the knowledge it took for engineering transmissions, making sure the ratios of rpm can be shifted by, "I have several spool trailers with the same size drive gears and the same size driven gears. Fuse Holders It is a new Byers Starmaster, 359 tooth gear. A taller(? So detailed, so basic, so easy to understand. I guess I'm being dense. Isn't there something available like this kit? The red PCB is the stepper driver module it's an Allegro A4988 chopper driver. After 10:1 reduction, the output shaft moves at 0.18 degrees per step. 30/7 = about, In our example, the intermediate gear ratios are 20/7 =. Was I denied boarding incorrectly by TUI to the USA from Birmingham UK due to visa issues. The stepper motor has most difficult to handle when just doing a few steps, when moving hundred steps or more it works fine. Asking for help, clarification, or responding to other answers. One complete turn of the worm = 1 tooth. The Gear ratio is the ratio of the number of teeth of the driven gear and driver gear. Connectors down torque gear train step speed transformers reducing transformer stepping steps while electric example ac electrical miracles In mechanical engineering, a gear ratio is a direct measure of the ratio of the rotational speeds of two or more interlocking gears. How to tell reviewers that I can't update my results. For example purposes, let's say that you have one small drive gear (gear 1) turning a larger driven gear (gear 2). This article received 63 testimonials and 84% of readers who voted found it helpful, earning it our reader-approved status. If a 38 tooth gear running at 360rpm is driving another gear at 144rpm, what is the number of teeth on the driven gear? If the angular velocity of mating gear is constant we can conclude to the following relation: Where 1 and 2: Angular Velocity in radian/sec for driver and driven gear respectively. With a standard 180:1 worm drive and two 3:1 belt reducers (I have modified it to take two reducers), 400 step stepper motor and 16 bit micro step I get 0.125" / step. It is used to calculate the speed and torque of the output shaft when input and output shafts are connected using a gear train. The QM-57-83 is a NEMA 23 frame stepper with a draw of 0.9 amps, but I can't find any information on the number of steps per rotation. According to the law of gears. The cookie is used to store the user consent for the cookies in the category "Other. http://www.astrofriend.eu/astronomy/astronomy-calculations/mount-gearbox-ratio/mount-gearbox-ratio.html. I assume that I should spread the ratios for the other gears, but my current spread makes no sense to me (4.45, 2.59, 1.63, 1.11, 0.81, 0.62). Copyright 2020 Weddle Industries.

"I am currently in school for my airframe and power plant licenses, and this helped me gain the confidence work. I have a tangent drive on the other axis, so it will be only the one motor. Tires wikiHow is a wiki, similar to Wikipedia, which means that many of our articles are co-written by multiple authors. Yes. Rims Cheers Thanks. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. In this application it will drive the stepper at sidereal as well as 2X and 8X for corrections. Any ideas? In This Week's Tele Vue Blog: Telescope vs. Super-Telephoto Lens for Imaging? In this article, we will discuss how to calculate gear ratio, speed, and torque for various gear trains. By using this site, you agree to our Terms of Use. Thanks for the response. made for electric bicycles with 16" through 26" wheels. If you substitute an 80-tooth spur gear instead of the 100-tooth, then you could use a 1-rpm motor. For example, power from the engine is transferred to the wheels through the gearbox. Step-3: By Multiplying gear-ratio between 1 to 2 and 2 to 3. Once you know that, it's very simple math to determine the ratio. Gear down is to drive a larger gear with a smaller gear creating a slower RPM at the output but more torque. I assume this means that the stepper motor has an attached gear head. If include gear ratio factor, my motor speed is 6rpm. I'm sure this has been covered many times, but I was unable to find it in a search. The power needed to drive the load is geared up or down from the motor by the gear ratio. We suggest you first read this article on Reduction Gears. Standard motors should not be used for electric bicycle projects unless a There are other drivers that sell for under $10 that will support up to 250 microsteps/step, but more processor power than the Nano can provide are required. Belts also be increased above the top speed calculation by riding down hill, or riding When riding on flat ground the top speed is usually only reduced by a small amount. gear ratio rpm ratios gears compound calculation system driven motor driving rotation rev min introduction robotic 14core revolutions into affected To create this article, 33 people, some anonymous, worked to edit and improve it over time. gear calculator program trends performance trans calculate How do I determine my gear ratio in my gear box? These resistance factors Therefore if input torque is known. Otherwise, the motors steps will be obvious. While stepper are very accurate and flexible all these charatteristics should be taken into account when using them. Can I substitute an electric motor? So a gear with 80 teeth compared to a compatible gear with 100 teeth should have 80% of the diameter. We will do our best to add it to this post. Background from the industry, or? Maybe cheaper in future because of the lack of mechanical gears. Electric Scooter Repair Help | Use MathJax to format equations. I have read at other threads you started, you build a lot of equipment your self I understand. This article has been viewed 1,546,022 times. All Parts When driver gear is rotated in a clockwise direction, driven gear will rotate in the anti-clockwise direction. It's easy!

"I am currently in school for my airframe and power plant licenses, and this helped me gain the confidence work. I have a tangent drive on the other axis, so it will be only the one motor. Tires wikiHow is a wiki, similar to Wikipedia, which means that many of our articles are co-written by multiple authors. Yes. Rims Cheers Thanks. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. In this application it will drive the stepper at sidereal as well as 2X and 8X for corrections. Any ideas? In This Week's Tele Vue Blog: Telescope vs. Super-Telephoto Lens for Imaging? In this article, we will discuss how to calculate gear ratio, speed, and torque for various gear trains. By using this site, you agree to our Terms of Use. Thanks for the response. made for electric bicycles with 16" through 26" wheels. If you substitute an 80-tooth spur gear instead of the 100-tooth, then you could use a 1-rpm motor. For example, power from the engine is transferred to the wheels through the gearbox. Step-3: By Multiplying gear-ratio between 1 to 2 and 2 to 3. Once you know that, it's very simple math to determine the ratio. Gear down is to drive a larger gear with a smaller gear creating a slower RPM at the output but more torque. I assume this means that the stepper motor has an attached gear head. If include gear ratio factor, my motor speed is 6rpm. I'm sure this has been covered many times, but I was unable to find it in a search. The power needed to drive the load is geared up or down from the motor by the gear ratio. We suggest you first read this article on Reduction Gears. Standard motors should not be used for electric bicycle projects unless a There are other drivers that sell for under $10 that will support up to 250 microsteps/step, but more processor power than the Nano can provide are required. Belts also be increased above the top speed calculation by riding down hill, or riding When riding on flat ground the top speed is usually only reduced by a small amount. gear ratio rpm ratios gears compound calculation system driven motor driving rotation rev min introduction robotic 14core revolutions into affected To create this article, 33 people, some anonymous, worked to edit and improve it over time. gear calculator program trends performance trans calculate How do I determine my gear ratio in my gear box? These resistance factors Therefore if input torque is known. Otherwise, the motors steps will be obvious. While stepper are very accurate and flexible all these charatteristics should be taken into account when using them. Can I substitute an electric motor? So a gear with 80 teeth compared to a compatible gear with 100 teeth should have 80% of the diameter. We will do our best to add it to this post. Background from the industry, or? Maybe cheaper in future because of the lack of mechanical gears. Electric Scooter Repair Help | Use MathJax to format equations. I have read at other threads you started, you build a lot of equipment your self I understand. This article has been viewed 1,546,022 times. All Parts When driver gear is rotated in a clockwise direction, driven gear will rotate in the anti-clockwise direction. It's easy!