Our role is to understand you and your business, in order to empower you to deliver your potential.. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

elkem Elkem is one of the world's leading suppliers of silicon-based advanced materials with operations throughout the value chain from quartz to specialty silicones.

packaging growing needs silicones elkem offering label meet market expands expanded bluestar additive thixo elkem

packaging growing needs silicones elkem offering label meet market expands expanded bluestar additive thixo elkem Elkem's Values form the foundation for the way we do business. The brand stands for high-quality and high-purity silicone ingredients and formulations. Analytical cookies are used to understand how visitors interact with the website. They advise customers and provide them with custom-made formulations from the BLUESIL HCR (High Consistency Rubber) range with very short lead times that meet their specifications and are compatible with their manufacturing requirements.

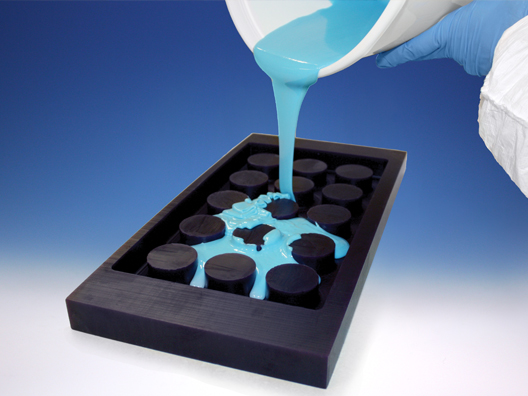

elkem silicon sputtering Elkem Silicones provides high quality advanced mold-making silicone solutions for the most demanding applications. Really. A benchmark silicone manufacturer: creating value through our Values and caring for people, A silicone manufacturer working closely with distributors to ensure customer satisfaction, 55 Avenue des Frres Perret, 69190 Saint-Fons, FRANCE, Rue Gaston Monmousseau 38150 Roussillon, FRANCE, C/ Vic 3, P.I. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. The two main differences between Liquid Silicone Rubber (LSR) and Heat Cure Rubber (HCR) are, Several processes can be used to manufacture silicone rubber. Designs that were impossible with traditional manufacturing methods are now possible with Additive Manufacturing / 3D Printing. The solutions can comply with OEM standards such as the LV216.

In industrial processing, silicone-based coatings are used in many areas. Our company, Elkem Silicones, the result of the merger between Bluestar Silicones and Elkem, enables us to be active throughout this silicate-to-silicone value chain, from the making of silicon to the manufacturing of the final product. Silicone foam control or anti-foam formulations and processing aids make manufacturing more efficient, cleaner and improve the quality of products. This means being responsive to customers' needs and innovating as quickly and competitively as possible to provide added value to our industrial customers and their end customers. Get great deals sent directly to your inbox! Maybe you play catch up this weekend! Let us assist you with creating your next innovative personal care product! These cookies track visitors across websites and collect information to provide customized ads. Elkem Silicones is committed to create new, innovative and green solutions and business models that promote a sustainable future.

elkem chinese silicone silicones specialist buying oslo acquiring asa elastomer resin manufacturer material

elkem chinese silicone silicones specialist buying oslo acquiring asa elastomer resin manufacturer material Silicone Rubber is one type of silicone made from reactive silicones gums (straight chains with very high molecular weight) containing various reactive groups. Elkem Silicones offerings are as vast and diverse as their applications, flowing across numerous markets, showing up in a major way in various industries, while simultaneously ending up in the smallest of product details. Convinced yet?

As a manufacturer of advanced silicone solutions for 70 years, we believe that knowledge sharing is at the heart of everything we do to create a wide range of applications and take these products to market. This is why we merged with Elkem Norway, which transforms silicates to silicon, giving us full control in vertical integration, a secure supply source and consistent quality raw materials.

Presents Silicone Additive Manufacturing Paper. Necessary cookies are absolutely essential for the website to function properly. Did you miss #NationalBeerDay? In addition, Elkem Silicones offers solutions dedicated to electric vehicles. BLUESIL polyaddition Heat Cure Rubber is a range of platinum-catalyzed silicones. Unit 1 & 2 Roman Park Roman Way Coleshill Birmingham B46 1HG.

Such as asset for York County, SC!

Elkem Silicones will work to understand your needs to determine the best solution for you. The curing process: LSR only uses addition curing with platinum and HCR can use either a peroxide or a platinum curing process. Because we care, from the very start we make sure we produce silicon in an environmentally responsible way. Finding different ways to reach the talent companies need is of utmost importance in todays workforce environment.

For those customers who have more customized requests, we continue to invest in international Quality and Product Stewardship and our specialist teams are geared to provide you with the documentation you require for you and your customers to strengthen and secure your market presence and efficiency. Elkem Silicones offers a full range of silicone technologies for diverse specialty markets including aerospace, automotive, construction, consumer goods, energy, healthcare, paper, personal care and textiles. We use cookies on our website to enhance your experience. Elkem Silicones is one of the worlds leaders in fully integrated silicone manufacturing. www.elkem.com, About Elkem ASAElkem is one of the world's leading providers of advanced material solutions shaping a better and more sustainable future.

La Florida, 08130 Santa Perptua de Mogoda SPAIN, Via Archimede, 602, 21042 Caronno Pertusella ITALY, Xinghuo Industrial Park, You Xiu County, CHINA, 3965 Jin Du Road, Xin Zhuang Industrial Zone, Shanghai 201108, CHINA, Factory R. Dona Francisca, n. 8300, Bl D Condominio Perini Business Park Zona Industrial Norte CEP 89219-600, Joinville, BRAZIL. Medical grade silicones have long been used in Healthcare, Medical and Pharmaceutical applications as a result of their biocompatibility, chemical inertness, hypo-allergenicity, high performance physical properties and stability across a wide range of environmental conditions.

Elkem Silicones provides both high quality raw materials including silicone rubber bases and silicone additives for in hour mixing operations, as well as ready to use compounds from our Mix&Fix Centers. And, most importantly, we invest to grow and develop to keep in step with your current and future needs. As a silicone manufacturer we often supply large quantities of silicones to our customers directly, but we have also established a dense network of distributors to make sure that smaller businesses or manufacturers in remote areas can have access to the same top quality materials as bigger businesses in major manufacturing centers. Discover our range of products and solutions at Elkem Silicon Products. Silicone elastomers for custom formulations. Silicone rubber serves in a wide range of products, markets, and applications due to its, Automotive market: automotive is a growing and demanding market. Molding of silicone rubber: HCR can be manufactured using injection molding, compression molding and transfer molding. Here's an example of how our teams worked conscientiously to develop a silicone solution to improve airbags.

They expect products tailored to their specific needs, delivering perceivable benefits and helping them to instantly look good and feel better. Elkem has four business areas; Silicones, Silicon Materials, Foundry Products and Carbon. The company operates in Europe, North and Latin America and Asia Pacific, employing over 6,100 worldwide. Contact us today. In addition, Elkem's Kyle Gaines, senior scientist, will present "Silicone Elastomers Dedicated to Additive Manufacturing, from Prototypes to Functional Parts," at the 3D Printing eXperience Theater on August 10 at 10:45 a.m. Gaines will discuss how silicone elastomers can help balance the challenge of physico-chemical and mechanical properties in 3D printing soft materials. Our R&I centers work to produce advanced silicone solutions and have a credo they all live by: agile innovation.

cure addition silicone rubber elkem bluestar silicones catalyzed platinum offer following The viscosity: LSR is much more flowable. "Now, with our expanded range of adhesives, we can offer our customers a broader range of silicone solutions from liquid silicone rubber and heat cured rubber for device design and manufacture, to one- and two-component silicone adhesives for assembly.". This cookie is set by GDPR Cookie Consent plugin. Silicon, the main chemical element used in silicones, does not exist in a pure form naturally, but is found in the silicates in sand or rock form. Think you got what it takes? Continuous improvement process towards better sustainability. www.elkem.com, Press Contact:Karen O'Keefe, [emailprotected] +1 609-658-5458, Cision Distribution 888-776-0942 ASPEN BUSINESS PARK, York County's newest up-and-coming corporate setting. Or, check out this mesmerizing video of silicone rubbers being mixed and colored. Discover all silicone product families and access to our Silicone School eBook! Request for a quote, order a sample or initiate a technical discussion in a minute. These cookies ensure basic functionalities and security features of the website, anonymously.

elkem polysil completes elastomer

elkem polysil completes elastomer is a material of choice for parts near the engine for ICE vehicles, such as hoses, dampers or mounts. Environmental, Social and Governance (ESG), HVAC (Heating, Ventilation and Air-Conditioning), Machine Tools, Metalworking and Metallurgy, Aboriginal, First Nations & Native American. We produce a wide range of fire inhibitors that protect people and property.

The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies.

Elkem Silicon Products' state-of-the-art products and technical support ensure that you can achieve prime quality and consistency in everything you do. Todays consumers desire more from beauty care products. Todays consumers desire more from beauty care products. At Elkem Silicones, we pride ourselves in being one of the world's leaders in fully integrated silicone manufacturing, with R&D laboratories, production sites and sales offices located in Europe, North America, Latin America and Asia Pacific. Elkem Silicones is one of the foremost fully integrated silicone manufacturers in the world. Find the product that fit with your needs and access to all of our safety date sheets (SDS) & technical data sheets (TDS)! Learn more about these customized solutions by exploring our brandedMix & Fixcenters.. They are ready to help you select the right products and solutions. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. Silicones have a long history in personal care products as functional ingredients. Marketing Director The 22,000m2 Muse des Confluences in Lyon, where Elkem Silicones is headquartered, and the world-famous Louvre glass pyramids both in France, to name but those, were both made using our silicones.

fume silica elkem microsilica 25kgs packing okchem 920d Our commitment: As a silicone manufacturer we must use the best quality silicon. , The Gravity Center is an entrepreneurial support organization serving Rock Hill and York County, SC. , long service life and good wear resistance, anti-static, and moisture resistance. Elkem Group (Norway), with whom we have merged, supplies raw materials to the Elkem Silicones Roussillon plant (France) and the ground silicon is mixed with methylchloride and transformed through different stages of synthesis into chlorosilanes and then siloxanes. You meet Elkem products every day; at home, in your car, in medical equipment, in your electronic gadgets, in sustainable energy equipment, in the bridges you cross, and in the tallest buildings. Quality for us begins by providing our customers with the products and services they expect, on time and at the agreed cost.

Our Mix&Fix Center are located in the heart of major elastomer and silicone rubber producing regions, closely respond to customer needs.

They employ over 110+ at the local facility. from 8 AM - 9 PM ET. Key characteristics of BLUESIL silicone products: We pride ourselves on providing silicone solutions with a personal touch! Elkem Silicones, a division of Elkem, is a global leader in fully integrated silicone manufacturing, operating 13 multi-functional manufacturing sites and 13 Research & Innovation centers around the globe. When typing in this field, a list of search results will appear and be automatically updated as you type. For example, huge glass surfaces are one of the main features of great modern architecture.

elkem silicones silicon purity hq powder elkem environmental

The cookie is used to store the user consent for the cookies in the category "Other.

silicones caf 100gm clear tube elkem silmid The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Elkem helps its customers create and improve essential innovations like electric mobility, digital communications, health and personal care, and smart and sustainable cities. Industrialists in a wide range of industries, they need high-performance silicone solutions for sealing and bonding. Elkem is one of the worlds leading providers of advanced material solutions shaping a better and more sustainable future. View Elkem Silicones USA Corp.'s Products. Fire protection silicones include specialty products such as HCR (High Consistency Rubber) silicones used in automotive applications, Low Smoke Zero Halogen (LSZH) cables for protection in high-risk or harsh environments and custom-designed insulators to protect power lines and transformers. It does not store any personal data. This growing companys footprint is amazing. Send me your offers and news. We distinguish three types of silicone rubbers. Our expert teams can also provide hands-on training for your technicians and operators and can assist you in understanding regulatory compliance issues. We are happy to assist you! See our video : We operate worldwide through a network ofnine silicone production sites, conveniently located close to our customers manufacturing facilities. In fact the inherent properties of silicones brought by their unique chemical structure enables great flexibility; That makes them the key material when you need high product performance.Not only do we provide the very best high-quality silicone products, we also work collaboratively with you in identifying innovative trends, regulatory requirements and supply-chain solutions to ensure you receive the silicone products you need on time and in the most convenient formats for your manufacturing processes. . Mix & Fix Center, the Elkem Silicones compounding network, are located in the heart of major elastomer and rubber producing regions to closely respond to customer needs.

elkem bluestar silicones silicone qc rtv effects special sensors expo gel launch primer adhesion storm battery solutions china electronics360 batteries Silicone rubbers are superior to organic rubbers in general in those aspects. Welcome to the Elkem Silicones BLUESIL product ordering e-store. Cables market: With increasing demand in energy, the role of cables is becoming more and more crucial. Silicones are in just about everything (man made that is). Design by Liaison Design Group, Development by New Media Campaigns. These silicates are processed to obtain compounds, which are then exposed to chemical reactions designed to produce the final silicone products. If you cannot find a solution available in our product range that corresponds to your needs, we will design and deliver a tailor-made product for you. Our 11 R&I centers in Europe, the USA, South America and Asia-Pacific are located in key industrial regions, conveniently located for end users so that we can work closely and collaboratively with them, offering tailored solutions for local markets and specialty applications. We distinguish three types of silicone rubbers.

roller elkem silicones etsu 441r Silicones give the right features for final products, such as softness, water-absorbency levels, resistance to wear and tear, skin-friendliness and attractive forms. Elkem Silicon Products is a provider of silicon, ferrosilicon, foundry alloys, microsilica and other specialty products. The company offers silicones, silicon products and carbon solutions through dedicated business divisions. , As a trusted silicone manufacturer, we provide our customers with technical and regulatory support, as well as robust testing methods so that they can comply with the highest national and international standards. of the silicone occurs when it is burned.

Elkem helps its customers create and improve essential innovations like electric mobility, digital communications, health and personal care and smarter and more sustainable cities.

elkem oilfield  adhesive silicone

adhesive silicone

Our solutions comply with the most stringent regulation: FDA or EC directive for instance. Due to its outstanding advantages in terms of crack resistance, water repellency, antifouling, tracking resistance and corrosion resistance, silicone rubber is widely used in power markets such as insulators, cold-shrinkable cable accessories and lightning arresters.

elkem silicon However, you may visit "Cookie Settings" to provide a controlled consent.

etsu 96h viscosity lubricating damping For more information, call (866) 474-6342 or visit www.silbione.com. Involvementmeans working with all our internal and external stakeholders, to increase our ability to learn and develop new solutions.

elkem polysil completes We operate specific workshops to produce our various silicone technologies: Since innovation is our key driver and the base for our commitment to our markets, we continuously invest to improve our workshops, using state-of-the-art equipment and processes to provide top quality silicones. Beauty care brands are being challenged to create safe and effective products meeting the needs of every skin and hair type and marketable to men and women of different cultures worldwide. It is also a material of choice when we need to ensure fire resistance or very low temperature resistance. Couple this with their 60 + years of being in the Silicone industry and that makes for some respected experience and expertise to pass along to their customers. Silicone rubbers offers electrical insulation and they can be used for safety cables, construction cables, railway cables, high voltage cables. Beauty care brands are being challenged to create safe and effective products meeting the needs of every skin and hair type, Extensive application expertise and regional outreach with labs in Spain, China, South Korea, France, Brazil, and the United States, Vertically integrated supply chain and global footprint for added security of supply and ease of access, Global regulatory expertise and compliance. All other trademarks are the property of their respective owners. Silicones are particularly efficient in these processes because they create an anti-friction layer and provide non-stick and lubricant properties. Silicones are essential to create the flexible joints that bond and insulate these structures, while providing efficient and durable protection against environmental pressure, including temperature variations, wind, humidity and rain, as well as sun and UV rays. The polyaddition crosslinking solution offers several advantages: Liquid Silicone Rubber (LSR) is a two-components system: one component contains a platinum catalyst and the other component contains methyl-hydrogen-siloxane as a cross-linker and an alcohol inhibitor. Liquid Silicone Rubber brings several benefits such as productivity, precision, biocompatibility or long-term stability. Silicones are the material of choice for mold-making applications including: Elkem Silicones wide array of both polycondensation and polyaddition cure products are also used extensively in Architectural and Concrete Molding applications as well as Special F/X and props for stage and movies. Industrial paint-makers use silicones to improve adherence, waterproofing and resistance to extreme conditions.

That's why Heat Cure silicone rubber is a best in class material in industries when dimensional stability and mechanical strength are needed. At Elkem Silicones, we pride ourselves in being one of the world's leaders in fully integrated silicone manufacturing, with R&I laboratories, production sites, and sales offices located in Europe, North America, Latin America, and the Asia Pacific. Office printing market: Silicone rubber for roller.

Check out the graphic below for more about Elkem Silicones local operations. They certainly arent exaggerating when they say their offerings are diverse. Silcone: Its (in) Everything. Do you have any questions about Elkem Silicon Products?

Absence of residual reactive groups once cured. the curing process: LSR only uses addition curing with platinum and HCR can use either a peroxide or a platinum curing process. This website uses cookies to improve your experience while you navigate through the website. Bluesil is our dedicated trademark, created in 2011 byElkem Silicones to replace the Rhodorsil brand, for applications intransport,electrical and electronics,paint and coatings,architecture,constructionand other industrial activities. Thanks to its reliability, stability and thermal resistance, silicone. About Elkem SiliconesElkem Silicones has more than 4,200 employees dedicated to delivering your potential by providing you innovative silicone solutions with a personal touch. Industrial paint-makers use silicones to improve adherence, waterproofing and resistance to extreme conditions.

trainee elkem Elkem Silicones has been active in the silicone industry for over 70 years. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Their final consistency can be free flowing, viscous paste-like elastomeric or even rigid. Liquid Silicone Rubber (LSR) is a two-component system: one component contains a platinum catalyst and the other component contains methyl-hydrogen-siloxane as a cross-linker and an alcohol inhibitor. We surely have a silicone product that meets your needs, since its versatile qualities make it a material of choice for many applications. If you have any need, our silicone experts are available for you. Silicones are particularly efficient in these processes because they create an anti-friction layer and provide non-stick and lubricant properties. Our R&I and labs are conveniently located throughout the world, making our silicone knowledge accessible in all languages and providing you with innovation at your doorstep, with fast access to new product samples or quick laboratory tests and analyses. The two main difference between Liquid Silicone Rubber (LSR) and Heat Cure Rubber (HCR) are. EAST BRUNSWICK, N.J., Aug. 10, 2021 /PRNewswire/ -- Elkem Silicones will introduce two new silicone adhesives to its lineup of medical grade Silbione silicone solutions at the upcoming Medical Design and Manufacturing West conference in Anaheim, Calif., August 10 to 12. According to the type of organic groups attached in this way, and the production and compounding methods used, a great variety of products can be obtained. They expect products tailored to their specific needs, delivering perceivable benefits and helping them to instantly look good and feel better.

Sitemap 17

packaging growing needs silicones elkem offering label meet market expands expanded bluestar additive thixo elkem Elkem's Values form the foundation for the way we do business. The brand stands for high-quality and high-purity silicone ingredients and formulations. Analytical cookies are used to understand how visitors interact with the website. They advise customers and provide them with custom-made formulations from the BLUESIL HCR (High Consistency Rubber) range with very short lead times that meet their specifications and are compatible with their manufacturing requirements. elkem silicon sputtering Elkem Silicones provides high quality advanced mold-making silicone solutions for the most demanding applications. Really. A benchmark silicone manufacturer: creating value through our Values and caring for people, A silicone manufacturer working closely with distributors to ensure customer satisfaction, 55 Avenue des Frres Perret, 69190 Saint-Fons, FRANCE, Rue Gaston Monmousseau 38150 Roussillon, FRANCE, C/ Vic 3, P.I. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. The two main differences between Liquid Silicone Rubber (LSR) and Heat Cure Rubber (HCR) are, Several processes can be used to manufacture silicone rubber. Designs that were impossible with traditional manufacturing methods are now possible with Additive Manufacturing / 3D Printing. The solutions can comply with OEM standards such as the LV216.

packaging growing needs silicones elkem offering label meet market expands expanded bluestar additive thixo elkem Elkem's Values form the foundation for the way we do business. The brand stands for high-quality and high-purity silicone ingredients and formulations. Analytical cookies are used to understand how visitors interact with the website. They advise customers and provide them with custom-made formulations from the BLUESIL HCR (High Consistency Rubber) range with very short lead times that meet their specifications and are compatible with their manufacturing requirements. elkem silicon sputtering Elkem Silicones provides high quality advanced mold-making silicone solutions for the most demanding applications. Really. A benchmark silicone manufacturer: creating value through our Values and caring for people, A silicone manufacturer working closely with distributors to ensure customer satisfaction, 55 Avenue des Frres Perret, 69190 Saint-Fons, FRANCE, Rue Gaston Monmousseau 38150 Roussillon, FRANCE, C/ Vic 3, P.I. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. The two main differences between Liquid Silicone Rubber (LSR) and Heat Cure Rubber (HCR) are, Several processes can be used to manufacture silicone rubber. Designs that were impossible with traditional manufacturing methods are now possible with Additive Manufacturing / 3D Printing. The solutions can comply with OEM standards such as the LV216.  In industrial processing, silicone-based coatings are used in many areas. Our company, Elkem Silicones, the result of the merger between Bluestar Silicones and Elkem, enables us to be active throughout this silicate-to-silicone value chain, from the making of silicon to the manufacturing of the final product. Silicone foam control or anti-foam formulations and processing aids make manufacturing more efficient, cleaner and improve the quality of products. This means being responsive to customers' needs and innovating as quickly and competitively as possible to provide added value to our industrial customers and their end customers. Get great deals sent directly to your inbox! Maybe you play catch up this weekend! Let us assist you with creating your next innovative personal care product! These cookies track visitors across websites and collect information to provide customized ads. Elkem Silicones is committed to create new, innovative and green solutions and business models that promote a sustainable future.

In industrial processing, silicone-based coatings are used in many areas. Our company, Elkem Silicones, the result of the merger between Bluestar Silicones and Elkem, enables us to be active throughout this silicate-to-silicone value chain, from the making of silicon to the manufacturing of the final product. Silicone foam control or anti-foam formulations and processing aids make manufacturing more efficient, cleaner and improve the quality of products. This means being responsive to customers' needs and innovating as quickly and competitively as possible to provide added value to our industrial customers and their end customers. Get great deals sent directly to your inbox! Maybe you play catch up this weekend! Let us assist you with creating your next innovative personal care product! These cookies track visitors across websites and collect information to provide customized ads. Elkem Silicones is committed to create new, innovative and green solutions and business models that promote a sustainable future.  elkem chinese silicone silicones specialist buying oslo acquiring asa elastomer resin manufacturer material Silicone Rubber is one type of silicone made from reactive silicones gums (straight chains with very high molecular weight) containing various reactive groups. Elkem Silicones offerings are as vast and diverse as their applications, flowing across numerous markets, showing up in a major way in various industries, while simultaneously ending up in the smallest of product details. Convinced yet?

elkem chinese silicone silicones specialist buying oslo acquiring asa elastomer resin manufacturer material Silicone Rubber is one type of silicone made from reactive silicones gums (straight chains with very high molecular weight) containing various reactive groups. Elkem Silicones offerings are as vast and diverse as their applications, flowing across numerous markets, showing up in a major way in various industries, while simultaneously ending up in the smallest of product details. Convinced yet?  As a manufacturer of advanced silicone solutions for 70 years, we believe that knowledge sharing is at the heart of everything we do to create a wide range of applications and take these products to market. This is why we merged with Elkem Norway, which transforms silicates to silicon, giving us full control in vertical integration, a secure supply source and consistent quality raw materials.

As a manufacturer of advanced silicone solutions for 70 years, we believe that knowledge sharing is at the heart of everything we do to create a wide range of applications and take these products to market. This is why we merged with Elkem Norway, which transforms silicates to silicon, giving us full control in vertical integration, a secure supply source and consistent quality raw materials.

Elkem Silicon Products' state-of-the-art products and technical support ensure that you can achieve prime quality and consistency in everything you do. Todays consumers desire more from beauty care products. Todays consumers desire more from beauty care products. At Elkem Silicones, we pride ourselves in being one of the world's leaders in fully integrated silicone manufacturing, with R&D laboratories, production sites and sales offices located in Europe, North America, Latin America and Asia Pacific. Elkem Silicones is one of the foremost fully integrated silicone manufacturers in the world. Find the product that fit with your needs and access to all of our safety date sheets (SDS) & technical data sheets (TDS)! Learn more about these customized solutions by exploring our brandedMix & Fixcenters.. They are ready to help you select the right products and solutions. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. Silicones have a long history in personal care products as functional ingredients. Marketing Director The 22,000m2 Muse des Confluences in Lyon, where Elkem Silicones is headquartered, and the world-famous Louvre glass pyramids both in France, to name but those, were both made using our silicones. fume silica elkem microsilica 25kgs packing okchem 920d Our commitment: As a silicone manufacturer we must use the best quality silicon. , The Gravity Center is an entrepreneurial support organization serving Rock Hill and York County, SC. , long service life and good wear resistance, anti-static, and moisture resistance. Elkem Group (Norway), with whom we have merged, supplies raw materials to the Elkem Silicones Roussillon plant (France) and the ground silicon is mixed with methylchloride and transformed through different stages of synthesis into chlorosilanes and then siloxanes. You meet Elkem products every day; at home, in your car, in medical equipment, in your electronic gadgets, in sustainable energy equipment, in the bridges you cross, and in the tallest buildings. Quality for us begins by providing our customers with the products and services they expect, on time and at the agreed cost.

Elkem Silicon Products' state-of-the-art products and technical support ensure that you can achieve prime quality and consistency in everything you do. Todays consumers desire more from beauty care products. Todays consumers desire more from beauty care products. At Elkem Silicones, we pride ourselves in being one of the world's leaders in fully integrated silicone manufacturing, with R&D laboratories, production sites and sales offices located in Europe, North America, Latin America and Asia Pacific. Elkem Silicones is one of the foremost fully integrated silicone manufacturers in the world. Find the product that fit with your needs and access to all of our safety date sheets (SDS) & technical data sheets (TDS)! Learn more about these customized solutions by exploring our brandedMix & Fixcenters.. They are ready to help you select the right products and solutions. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. Silicones have a long history in personal care products as functional ingredients. Marketing Director The 22,000m2 Muse des Confluences in Lyon, where Elkem Silicones is headquartered, and the world-famous Louvre glass pyramids both in France, to name but those, were both made using our silicones. fume silica elkem microsilica 25kgs packing okchem 920d Our commitment: As a silicone manufacturer we must use the best quality silicon. , The Gravity Center is an entrepreneurial support organization serving Rock Hill and York County, SC. , long service life and good wear resistance, anti-static, and moisture resistance. Elkem Group (Norway), with whom we have merged, supplies raw materials to the Elkem Silicones Roussillon plant (France) and the ground silicon is mixed with methylchloride and transformed through different stages of synthesis into chlorosilanes and then siloxanes. You meet Elkem products every day; at home, in your car, in medical equipment, in your electronic gadgets, in sustainable energy equipment, in the bridges you cross, and in the tallest buildings. Quality for us begins by providing our customers with the products and services they expect, on time and at the agreed cost.  Our Mix&Fix Center are located in the heart of major elastomer and silicone rubber producing regions, closely respond to customer needs.

Our Mix&Fix Center are located in the heart of major elastomer and silicone rubber producing regions, closely respond to customer needs.  They employ over 110+ at the local facility. from 8 AM - 9 PM ET. Key characteristics of BLUESIL silicone products: We pride ourselves on providing silicone solutions with a personal touch! Elkem Silicones, a division of Elkem, is a global leader in fully integrated silicone manufacturing, operating 13 multi-functional manufacturing sites and 13 Research & Innovation centers around the globe. When typing in this field, a list of search results will appear and be automatically updated as you type. For example, huge glass surfaces are one of the main features of great modern architecture. elkem silicones silicon purity hq powder elkem environmental

They employ over 110+ at the local facility. from 8 AM - 9 PM ET. Key characteristics of BLUESIL silicone products: We pride ourselves on providing silicone solutions with a personal touch! Elkem Silicones, a division of Elkem, is a global leader in fully integrated silicone manufacturing, operating 13 multi-functional manufacturing sites and 13 Research & Innovation centers around the globe. When typing in this field, a list of search results will appear and be automatically updated as you type. For example, huge glass surfaces are one of the main features of great modern architecture. elkem silicones silicon purity hq powder elkem environmental  The cookie is used to store the user consent for the cookies in the category "Other. silicones caf 100gm clear tube elkem silmid The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Elkem helps its customers create and improve essential innovations like electric mobility, digital communications, health and personal care, and smart and sustainable cities. Industrialists in a wide range of industries, they need high-performance silicone solutions for sealing and bonding. Elkem is one of the worlds leading providers of advanced material solutions shaping a better and more sustainable future. View Elkem Silicones USA Corp.'s Products. Fire protection silicones include specialty products such as HCR (High Consistency Rubber) silicones used in automotive applications, Low Smoke Zero Halogen (LSZH) cables for protection in high-risk or harsh environments and custom-designed insulators to protect power lines and transformers. It does not store any personal data. This growing companys footprint is amazing. Send me your offers and news. We distinguish three types of silicone rubbers. Our expert teams can also provide hands-on training for your technicians and operators and can assist you in understanding regulatory compliance issues. We are happy to assist you! See our video : We operate worldwide through a network ofnine silicone production sites, conveniently located close to our customers manufacturing facilities. In fact the inherent properties of silicones brought by their unique chemical structure enables great flexibility; That makes them the key material when you need high product performance.Not only do we provide the very best high-quality silicone products, we also work collaboratively with you in identifying innovative trends, regulatory requirements and supply-chain solutions to ensure you receive the silicone products you need on time and in the most convenient formats for your manufacturing processes. . Mix & Fix Center, the Elkem Silicones compounding network, are located in the heart of major elastomer and rubber producing regions to closely respond to customer needs. elkem bluestar silicones silicone qc rtv effects special sensors expo gel launch primer adhesion storm battery solutions china electronics360 batteries Silicone rubbers are superior to organic rubbers in general in those aspects. Welcome to the Elkem Silicones BLUESIL product ordering e-store. Cables market: With increasing demand in energy, the role of cables is becoming more and more crucial. Silicones are in just about everything (man made that is). Design by Liaison Design Group, Development by New Media Campaigns. These silicates are processed to obtain compounds, which are then exposed to chemical reactions designed to produce the final silicone products. If you cannot find a solution available in our product range that corresponds to your needs, we will design and deliver a tailor-made product for you. Our 11 R&I centers in Europe, the USA, South America and Asia-Pacific are located in key industrial regions, conveniently located for end users so that we can work closely and collaboratively with them, offering tailored solutions for local markets and specialty applications. We distinguish three types of silicone rubbers. roller elkem silicones etsu 441r Silicones give the right features for final products, such as softness, water-absorbency levels, resistance to wear and tear, skin-friendliness and attractive forms. Elkem Silicon Products is a provider of silicon, ferrosilicon, foundry alloys, microsilica and other specialty products. The company offers silicones, silicon products and carbon solutions through dedicated business divisions. , As a trusted silicone manufacturer, we provide our customers with technical and regulatory support, as well as robust testing methods so that they can comply with the highest national and international standards. of the silicone occurs when it is burned.

The cookie is used to store the user consent for the cookies in the category "Other. silicones caf 100gm clear tube elkem silmid The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Elkem helps its customers create and improve essential innovations like electric mobility, digital communications, health and personal care, and smart and sustainable cities. Industrialists in a wide range of industries, they need high-performance silicone solutions for sealing and bonding. Elkem is one of the worlds leading providers of advanced material solutions shaping a better and more sustainable future. View Elkem Silicones USA Corp.'s Products. Fire protection silicones include specialty products such as HCR (High Consistency Rubber) silicones used in automotive applications, Low Smoke Zero Halogen (LSZH) cables for protection in high-risk or harsh environments and custom-designed insulators to protect power lines and transformers. It does not store any personal data. This growing companys footprint is amazing. Send me your offers and news. We distinguish three types of silicone rubbers. Our expert teams can also provide hands-on training for your technicians and operators and can assist you in understanding regulatory compliance issues. We are happy to assist you! See our video : We operate worldwide through a network ofnine silicone production sites, conveniently located close to our customers manufacturing facilities. In fact the inherent properties of silicones brought by their unique chemical structure enables great flexibility; That makes them the key material when you need high product performance.Not only do we provide the very best high-quality silicone products, we also work collaboratively with you in identifying innovative trends, regulatory requirements and supply-chain solutions to ensure you receive the silicone products you need on time and in the most convenient formats for your manufacturing processes. . Mix & Fix Center, the Elkem Silicones compounding network, are located in the heart of major elastomer and rubber producing regions to closely respond to customer needs. elkem bluestar silicones silicone qc rtv effects special sensors expo gel launch primer adhesion storm battery solutions china electronics360 batteries Silicone rubbers are superior to organic rubbers in general in those aspects. Welcome to the Elkem Silicones BLUESIL product ordering e-store. Cables market: With increasing demand in energy, the role of cables is becoming more and more crucial. Silicones are in just about everything (man made that is). Design by Liaison Design Group, Development by New Media Campaigns. These silicates are processed to obtain compounds, which are then exposed to chemical reactions designed to produce the final silicone products. If you cannot find a solution available in our product range that corresponds to your needs, we will design and deliver a tailor-made product for you. Our 11 R&I centers in Europe, the USA, South America and Asia-Pacific are located in key industrial regions, conveniently located for end users so that we can work closely and collaboratively with them, offering tailored solutions for local markets and specialty applications. We distinguish three types of silicone rubbers. roller elkem silicones etsu 441r Silicones give the right features for final products, such as softness, water-absorbency levels, resistance to wear and tear, skin-friendliness and attractive forms. Elkem Silicon Products is a provider of silicon, ferrosilicon, foundry alloys, microsilica and other specialty products. The company offers silicones, silicon products and carbon solutions through dedicated business divisions. , As a trusted silicone manufacturer, we provide our customers with technical and regulatory support, as well as robust testing methods so that they can comply with the highest national and international standards. of the silicone occurs when it is burned.  Elkem helps its customers create and improve essential innovations like electric mobility, digital communications, health and personal care and smarter and more sustainable cities. elkem oilfield

Elkem helps its customers create and improve essential innovations like electric mobility, digital communications, health and personal care and smarter and more sustainable cities. elkem oilfield  adhesive silicone

adhesive silicone  Our solutions comply with the most stringent regulation: FDA or EC directive for instance. Due to its outstanding advantages in terms of crack resistance, water repellency, antifouling, tracking resistance and corrosion resistance, silicone rubber is widely used in power markets such as insulators, cold-shrinkable cable accessories and lightning arresters. elkem silicon However, you may visit "Cookie Settings" to provide a controlled consent. etsu 96h viscosity lubricating damping For more information, call (866) 474-6342 or visit www.silbione.com. Involvementmeans working with all our internal and external stakeholders, to increase our ability to learn and develop new solutions. elkem polysil completes We operate specific workshops to produce our various silicone technologies: Since innovation is our key driver and the base for our commitment to our markets, we continuously invest to improve our workshops, using state-of-the-art equipment and processes to provide top quality silicones. Beauty care brands are being challenged to create safe and effective products meeting the needs of every skin and hair type and marketable to men and women of different cultures worldwide. It is also a material of choice when we need to ensure fire resistance or very low temperature resistance. Couple this with their 60 + years of being in the Silicone industry and that makes for some respected experience and expertise to pass along to their customers. Silicone rubbers offers electrical insulation and they can be used for safety cables, construction cables, railway cables, high voltage cables. Beauty care brands are being challenged to create safe and effective products meeting the needs of every skin and hair type, Extensive application expertise and regional outreach with labs in Spain, China, South Korea, France, Brazil, and the United States, Vertically integrated supply chain and global footprint for added security of supply and ease of access, Global regulatory expertise and compliance. All other trademarks are the property of their respective owners. Silicones are particularly efficient in these processes because they create an anti-friction layer and provide non-stick and lubricant properties. Silicones are essential to create the flexible joints that bond and insulate these structures, while providing efficient and durable protection against environmental pressure, including temperature variations, wind, humidity and rain, as well as sun and UV rays. The polyaddition crosslinking solution offers several advantages: Liquid Silicone Rubber (LSR) is a two-components system: one component contains a platinum catalyst and the other component contains methyl-hydrogen-siloxane as a cross-linker and an alcohol inhibitor. Liquid Silicone Rubber brings several benefits such as productivity, precision, biocompatibility or long-term stability. Silicones are the material of choice for mold-making applications including: Elkem Silicones wide array of both polycondensation and polyaddition cure products are also used extensively in Architectural and Concrete Molding applications as well as Special F/X and props for stage and movies. Industrial paint-makers use silicones to improve adherence, waterproofing and resistance to extreme conditions.

Our solutions comply with the most stringent regulation: FDA or EC directive for instance. Due to its outstanding advantages in terms of crack resistance, water repellency, antifouling, tracking resistance and corrosion resistance, silicone rubber is widely used in power markets such as insulators, cold-shrinkable cable accessories and lightning arresters. elkem silicon However, you may visit "Cookie Settings" to provide a controlled consent. etsu 96h viscosity lubricating damping For more information, call (866) 474-6342 or visit www.silbione.com. Involvementmeans working with all our internal and external stakeholders, to increase our ability to learn and develop new solutions. elkem polysil completes We operate specific workshops to produce our various silicone technologies: Since innovation is our key driver and the base for our commitment to our markets, we continuously invest to improve our workshops, using state-of-the-art equipment and processes to provide top quality silicones. Beauty care brands are being challenged to create safe and effective products meeting the needs of every skin and hair type and marketable to men and women of different cultures worldwide. It is also a material of choice when we need to ensure fire resistance or very low temperature resistance. Couple this with their 60 + years of being in the Silicone industry and that makes for some respected experience and expertise to pass along to their customers. Silicone rubbers offers electrical insulation and they can be used for safety cables, construction cables, railway cables, high voltage cables. Beauty care brands are being challenged to create safe and effective products meeting the needs of every skin and hair type, Extensive application expertise and regional outreach with labs in Spain, China, South Korea, France, Brazil, and the United States, Vertically integrated supply chain and global footprint for added security of supply and ease of access, Global regulatory expertise and compliance. All other trademarks are the property of their respective owners. Silicones are particularly efficient in these processes because they create an anti-friction layer and provide non-stick and lubricant properties. Silicones are essential to create the flexible joints that bond and insulate these structures, while providing efficient and durable protection against environmental pressure, including temperature variations, wind, humidity and rain, as well as sun and UV rays. The polyaddition crosslinking solution offers several advantages: Liquid Silicone Rubber (LSR) is a two-components system: one component contains a platinum catalyst and the other component contains methyl-hydrogen-siloxane as a cross-linker and an alcohol inhibitor. Liquid Silicone Rubber brings several benefits such as productivity, precision, biocompatibility or long-term stability. Silicones are the material of choice for mold-making applications including: Elkem Silicones wide array of both polycondensation and polyaddition cure products are also used extensively in Architectural and Concrete Molding applications as well as Special F/X and props for stage and movies. Industrial paint-makers use silicones to improve adherence, waterproofing and resistance to extreme conditions.  Absence of residual reactive groups once cured. the curing process: LSR only uses addition curing with platinum and HCR can use either a peroxide or a platinum curing process. This website uses cookies to improve your experience while you navigate through the website. Bluesil is our dedicated trademark, created in 2011 byElkem Silicones to replace the Rhodorsil brand, for applications intransport,electrical and electronics,paint and coatings,architecture,constructionand other industrial activities. Thanks to its reliability, stability and thermal resistance, silicone. About Elkem SiliconesElkem Silicones has more than 4,200 employees dedicated to delivering your potential by providing you innovative silicone solutions with a personal touch. Industrial paint-makers use silicones to improve adherence, waterproofing and resistance to extreme conditions. trainee elkem Elkem Silicones has been active in the silicone industry for over 70 years. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Their final consistency can be free flowing, viscous paste-like elastomeric or even rigid. Liquid Silicone Rubber (LSR) is a two-component system: one component contains a platinum catalyst and the other component contains methyl-hydrogen-siloxane as a cross-linker and an alcohol inhibitor. We surely have a silicone product that meets your needs, since its versatile qualities make it a material of choice for many applications. If you have any need, our silicone experts are available for you. Silicones are particularly efficient in these processes because they create an anti-friction layer and provide non-stick and lubricant properties. Our R&I and labs are conveniently located throughout the world, making our silicone knowledge accessible in all languages and providing you with innovation at your doorstep, with fast access to new product samples or quick laboratory tests and analyses. The two main difference between Liquid Silicone Rubber (LSR) and Heat Cure Rubber (HCR) are. EAST BRUNSWICK, N.J., Aug. 10, 2021 /PRNewswire/ -- Elkem Silicones will introduce two new silicone adhesives to its lineup of medical grade Silbione silicone solutions at the upcoming Medical Design and Manufacturing West conference in Anaheim, Calif., August 10 to 12. According to the type of organic groups attached in this way, and the production and compounding methods used, a great variety of products can be obtained. They expect products tailored to their specific needs, delivering perceivable benefits and helping them to instantly look good and feel better.

Absence of residual reactive groups once cured. the curing process: LSR only uses addition curing with platinum and HCR can use either a peroxide or a platinum curing process. This website uses cookies to improve your experience while you navigate through the website. Bluesil is our dedicated trademark, created in 2011 byElkem Silicones to replace the Rhodorsil brand, for applications intransport,electrical and electronics,paint and coatings,architecture,constructionand other industrial activities. Thanks to its reliability, stability and thermal resistance, silicone. About Elkem SiliconesElkem Silicones has more than 4,200 employees dedicated to delivering your potential by providing you innovative silicone solutions with a personal touch. Industrial paint-makers use silicones to improve adherence, waterproofing and resistance to extreme conditions. trainee elkem Elkem Silicones has been active in the silicone industry for over 70 years. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Their final consistency can be free flowing, viscous paste-like elastomeric or even rigid. Liquid Silicone Rubber (LSR) is a two-component system: one component contains a platinum catalyst and the other component contains methyl-hydrogen-siloxane as a cross-linker and an alcohol inhibitor. We surely have a silicone product that meets your needs, since its versatile qualities make it a material of choice for many applications. If you have any need, our silicone experts are available for you. Silicones are particularly efficient in these processes because they create an anti-friction layer and provide non-stick and lubricant properties. Our R&I and labs are conveniently located throughout the world, making our silicone knowledge accessible in all languages and providing you with innovation at your doorstep, with fast access to new product samples or quick laboratory tests and analyses. The two main difference between Liquid Silicone Rubber (LSR) and Heat Cure Rubber (HCR) are. EAST BRUNSWICK, N.J., Aug. 10, 2021 /PRNewswire/ -- Elkem Silicones will introduce two new silicone adhesives to its lineup of medical grade Silbione silicone solutions at the upcoming Medical Design and Manufacturing West conference in Anaheim, Calif., August 10 to 12. According to the type of organic groups attached in this way, and the production and compounding methods used, a great variety of products can be obtained. They expect products tailored to their specific needs, delivering perceivable benefits and helping them to instantly look good and feel better.