Read on to find out how we prefer to mount our volets or shutters. 1.

In the latter, designed originally for use with rebar, the anchor rod is hammered through a special capsule, drawing the catalyst through the resin. If you are an artisan that fits shutters for a living then the speed and convenience provided by the chemical is a no-brainer. Unlike the widely used but intrusive expansion anchors or plastic plugs, chemical anchors make the fixing an integral part of the substrate as the load is spread throughout the entire area, removing the stress caused within the substrate when these anchors or plugs are tightened up. Once it has set rock hard you can then go ahead and complete the job. Styrene free-resin is the safer option with a low-odour formula making it ideal for both internal and external use.

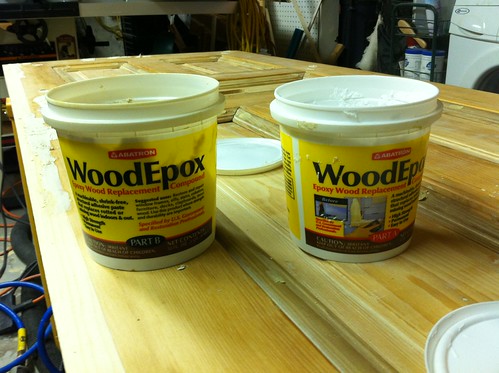

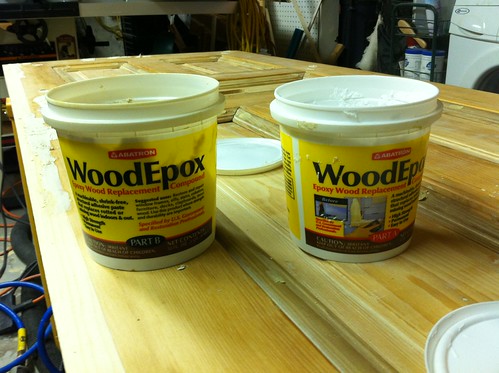

wood epoxy fill filler crack - fits into a normal 'mastic' Cosmetically are used for a chemical anchoring system makes for a neat job. In the former the specially shaped threaded anchor rod (or internally threaded socket) must be spun into the capsule, smashing it and mixing the contents in the process using a drilling machine via a drive adaptor. I History I Links If you get stuck you can make your own chemical fix. Thixotropic Injection Resin when mounting shutters on pintails you have to decide what type of print out you were going to use. Rapid Set - 6 to 8 minutes Rawl plugs are good for mounting fixed items to walls. A general purpose economical resin based on styrene, recommended for external use due to its hazardous nature. Apologies, but we don't seem to have a video for this project yet, but we will do our best to get one up soon. So weve established that resin systems can be stronger, work at closer edge and spacing dimensions, and offer a solution for masonry. Traditional products use a co-axial cartridge where the resin is packed into a cartridge which contains a central inner section that holds the hardener. total mixed volume is about 280cc. Dowels, for reinforcement or joining are available in high tensile plated steel or epoxy-glass in 6 25mm diameters. stitching and crack reinforcement. Full tables of relevant hole diameter sizes and loading strengths can usually be found on all packs and technical data, but for example for an M8 fixing a 10mm diameter hole would normally be used in concrete. Each tube contains two separate plastic bags: Resin capsule FHB II-P / FHB II-PF HIGH SPEED, Injection mortar FIS V, FIS VS LOW SPEED, FIS VW HIGH SPEED, Injection mortar FIS VL, FIS VL HIGH SPEED. Close-edge fixings - Our resin So while they do have some significant disadvantages the industry has been working hard to minimise their severity. Buy Now for Ceramic wash basins, urinals and sanitary installations, Installation accessories for subframe system, Continual Professional Development Seminars, Site Demo, Toolbox Talks and Installation Training, Solutions for Planners and structural engineers. Various applicator skeleton guns are available, depending upon which resin you choose. We also supply Chemical anchoring injection be used for horizontal, vertical and overhead applications. Find out how to drill holes and inject resin. nature of our systems minimises expensive on-site delays. How to use chemical anchors? foundation reinforcement and resin bolts into holes bored into masonry Contact If you need to fix close to the edge of a brick or stone pier because you need to hang a gate or fix a letterbox or nameplate, drilling and using screws and bolts which expand in their associated wall plugs may crack or split the masonry. Learn how your comment data is processed. The main Cons afflicting mechanical anchors relate to expansion types and derive from that characteristic. the flat type of Pinto we require you to create a slot for the Pintail to slide into. studding, nuts and washers to complete your anchor project. the bottom of the hole to about half way out.

epoxy chemical concrete adhesive resin anchor pure gu bonding bolt materials brick grouting bridge silicone hardware ltd use hollow nylon AVAILABLE - BUY IN BOXED QUANTITIES, ALL ORDERS GO Those who sell fixings should be careful not to imply that they can be placed close to an edge without any limit. The first group contains, obviously, anchors that are expanded, some by being tightened so called torque expanding anchors such as throughbolts (stud anchors), shield anchors and sleeve anchors and others that are expanded by the displacement of an expander plug (e.g drop-in anchors); while the second group contains undercut and self-tapping screw anchors (frequently referred to as concrete screws) and which are also categorised as a type of undercut anchor. Standard Set - 30 to 45 If they are aware of the above Pros and Cons they can make a choice between alternative anchor types that is appropriate to the particular application. Now however there are capsule anchors with ETA which require blowing only, but useful as this progress is, until all capsule anchors have this capability the best approach when training installers is to stress the need for thoroughly clean holes for all systems. Of course most anchors for use in safety critical applications are specified by an engineer they certainly should be and manufacturers software has made this otherwise very complex process relatively straightforward so, as long as the engineer inputs the right data in the first place, the software will recommend a possible range of suitable products with, effectively, the manufacturers endorsement. A key difference to another budget drill which produces the impact with a serrated gear. The SDS gives a stroke length of up to 18mm. The bonded anchor for cracked concrete without drill hole cleaning, The powerful injection mortar for rebar connections and cracked concrete, The basic epoxy mortar for applications in concrete, The powerful universal mortar for concrete and masonry, The versatile injection mortar for anchorings in masonry and cracked concrete, The solid injection mortar for standard applications in cracked concrete and masonry, The approved injection mortar for anchorings in masonry and non-cracked concrete, The reliable injection mortar for anchorings in masonry, The first approved injection mortar made with renewable raw materials, The cost-efficient epoxy mortar for applications in concrete, The best performance in cracked concrete for maximum tensile loads, The best performance in cracked concrete with the least installation effort. Our workshops are powered by 60% of electricity produced in an environmentally friendly way. (For Help with this calculation visit Property Repair Systems or give them a call on 01626 872 650). is stronger than the main substrate. document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); We are a small company manufacturing window shutters that has an affinity with the beautiful country that is France. 44 product families and 700 variants found. We are located in France but we are keen to share our experiences in the United States and the United Kingdom. You may already have the basic 300cc and/or 400cc skeleton guns, which are used with the Ultra Thixotropic Range, for example.Pure Epoxy it mixes in the nozzle ideal for anchoring bolts and barsPolyester Anchor Resin faster than Epoxies ideal for rapid anchor setting, Pure Epoxy it mixes in the nozzle ideal for anchoring bolts and bars, Polyester Anchor Resin faster than Epoxies ideal for rapid anchor setting. For these applications injection resin systems were developed and have largely displaced capsule systems in concrete too. Strength - The cured resin The nozzle has a spiral mixing device within the design. This product has a multitude of uses. 385cc - requires a 1:1 side by But in a safety critical application this is probably a small extra cost to pay in relation to the whole job. Manufacturers have been working hard on these aspects.

The hole is drilled to the required diameter dependent upon the threaded bar to be used, and the loading it has to take. This allows an optimum and secure solution to be offered for all applications, even under extreme construction site conditions such as wet, cold or heat: approved systems with resin capsules, injection mortars, threaded rods, internal threaded rods, anchor sleeves, accessories and processing equipment. At this point, you have opened the Tube and ideally, you need to use it. APPLICATION:Used to fix difficult materials or where fixing access is difficult.Widely used for fixing Balustrades, Handrails, Racking and holding down machinery plus many more installation applications. * Epoxy

fixings masonry types screws

We use an SDS type drill to drill a hole or create a slot.

Polyester 380P - concentric But before I expand on that I want to segregate mechanical anchors into two categories: Expansion anchors and non-expansion anchors. Plastic Rawlplugs is only good if the wall is firm and in good condition. An injection resin of the same basic resin may take typically four times as long. The flexibility in resin anchor selection referred to above comes from the scope to design the anchor to use a bond length between 4 and 20 times the anchor diameter (this is best facilitated by injection systems) and to specify a different rod strength. within the internationally recognised ISO 9001:2000 Quality System. Versatility - Our systems can Mark Salmon, Independent Fixing Consultants. in high chemical and vibration resistance of the anchor and resin. anchor chemicals, in cartridge tubes for nozzle mixing. systems put minimal stress on the main substrate allowing anchors to be The problem with any chemical anchor is that when it hardens you cannot adjust it anymore. Set the tape at a distance from the tube end to allow for the resin that will be displaced by the bar.

Screw on the supplied which has the spiral mix up inside. (Hons. Long-life - All the cartridges Inject gently, slowly removing the tube from the hole, to deposit resin without trapping air. BULK DISCOUNTS The information you need may be in the Project below, but if not call them for expert, unbiased assistance with building products. One above and one below I Whittle the material away with the SDS drill at an angle toshing the bit. Don't fancy doing this project yourself? However, best practice has, until recently, dictated that holes for resin anchors should always be thoroughly cleaned out using a process of both blowing (or vacuuming), brushing and blowing. Disadvantages of using chemical fix instead of expanding bolts. skeleton gun. down machinery, Benefits of using Resins Clicking on a blue Product We love feedback on our DIY tutorials it helps us to make them the best they possibly can be so if you have any comments you would like to share with us, click the button below and let us know. masonry, * Holding down bolts for steel I find chemical fix such a practical solution for the mounting of the shutter hinge pins or pintels. Getting ready to use chemical fix for the securing of shutter pintles or other things you want to fix into a wall is easy.

Working ethically is important to us. When using a chemical fix adhesive you are required how to drill a hole larger than the metal object us to fix into it. to Site Home Page and Indexes, E: Mail us help@propertyrepairsystems.co.uk, David Moore, B.A. Home > DIY How To Projects and Tutorial Guides > How to Use Chemical Fixings and Resin Anchors, This project is sponsored by Property Repair Systems. side dual piston skeleton gun, 6. Our anchor adhesives can be provided as epoxy anchor or polyester Convenience - Our systems avoid Next Day Delivery - Nationally, by T.N.T. The gun is the same as you would use with silicone mastic stuff that you would seal your bath with. Drill an oversized hole You will find that you will need to stock less variety. Like silicone mastic you just need to remove the end of the tube and insert into a mastic gun one. skeleton gun, 4. - mixes in the nozzle, mix Signing up to fastenerandfixing.com enables you to manage your account details. Some manufacturers have developed faster curing systems bringing curing times for capsules (for use with special anchor rods in cracked concrete) down to as little as a matter of minutes and injection systems, for general purpose anchoring, to half the standard times while still being slower than standard capsules. dual piston skeleton gun. This is misleading. The wood we use is certified by PEFC . The curing time is the other bugbear of resin anchors whereas mechanical anchors may be loaded immediately. Chemical versus mechanical anchors the pros and cons. For many years I have used chemical fix. These expanding bolts have been available for years. But what are the downsides? The ability of resin anchors to bond with the irregular shape of the drilled hole means they transfer the load very effectively along the full length of the bond using bond strengths that modern formulations have increased dramatically in recent years. in a side by side twin cartridge, with spiral mixing nozzle, * Polyester The cage type will do just fine. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned. Let us help you find a tradesman local to you. They have special characteristics for uses like rebar anchoring, which justify having to wait this long.

wire steel stainless cable balustrade trellis systems garden railing system s3i How To Use Bolts And Threaded Bars With Chemical Fixings For Heavy Duty Jobs, How To Use The Right Size Screw For Fixing, Types Of Screw For Different Uses - What Type Of Screw Should Be Used For What Kind Of Job Or Material Being Screwed. These were, and still are, very effective in concrete, but they dont work too well in masonry materials where resin can be lost in the voids caused by frogs (the V shaped depression in some bricks), in perforations and in the empty gaps between the leaves of solid brickwork. Single cartridge tube no hand mixing required two resins inside in a plastic bag fits standard skeleton guns resins mix in the nozzle, inside a spiral, which is replaced if the resin hardens before the tube is exhausted. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. These are rarely used and, in my opinion there is always something better, so, with limited space for this article, I will restrict my discussion to the spin-in type. If you have an old vacuum cleaner handy this can also work well.Injecting Resin Using Skeleton GunFloor Boards Removed. But it is the increased flexibility in the selection of resin anchors that has meant that, in most applications where loads need to be transferred into restricted sections of concrete or via a base plate of restricted dimensions, a resin system will provide a solution where a mechanical anchor, either expansion or undercut, just wont. The brushing bit removes the dust sticking to the sides of the hole. Chemical Fix is a polyester resin. Click here to go to our Shopping Pages. Each system is manufactured Injection Resin Slow Set, 1:1 side by Experience using this anchoring solution was in London East Barnet to be exact. In fact, the mixing of the two parts required for a chemical fix is done in the nozzle. It was surprising how tight you could tighten a nut. Whilst self-tapping screw anchors also introduce much lower stresses into the base material during installation and can be very strong in concrete, and work well in masonry, they dont offer such high strengths as chemical anchors and are best suited to temporary or short term applications. This Red plug is ideal for 4mm 4.5mm & 5mm diameter screws. One approach that safely avoids the need for separate hole cleaning operations is the adoption, by some manufacturers, of hollow drill bits which, when attached to a vacuum, will suck the dust from the hole as it is generated. - nozzle mixing means correct Resistance - Our systems result This is where chemical fixing can be a good choice. The Forgefix Resin injection system offers an easy fixing capability for numerous applications.

We supply spare spiral mixers. columns, * Tying back existing masonry A more convenient and easier to use packaging format, available on some anchorset products, is the twin bag system, where the contents are contained in two separate polythene bags in a one piece cartridge that allows application using a standard sealant cartridge gun; and also provides a much easier flow. We stock a range of bolts, SDS or Special Direct System was developed by Hilti and Bosch in 1975. They may be stress free during installation but as soon as you use them to transfer a load into the base material it becomes stressed. Reliability - Accurate 'self-mixing' This SDS uses the drill bit design to produces a long stroke impact. I have seen these expanding bolts used in brick or stone walls but these expanding bolts tend to split the brick. or chemical anchor resins, are used to secure anchor bolts, starter bars, The mixing of the hardener and the resin is done in the novel and this does not happen until you apply pressure to the handle of the mastic gun. Undercut anchors as such dont work well in masonry so must be considered for concrete only. Theres only one real problem with mechanical anchors, without which there might be no need for chemical anchors. Shop | Technical | References, Return THIXO RAPID ANCHOR RESIN is high loads into slim columns, * Fixing sanitary-ware to hollow Capsule systems have always been less sensitive than injection systems to poor hole cleaning as the spinning action, together with the chunky aggregate, tends to draw some of the dust left on the sides of the hole into the mix, whereas injection systems simply lay the resin against any dust left behind. Take the stud in the gloved hand and slowly rotate whilst pushing it into the resin filled hole. system for guaranteed quality. surfaces together. the problems encountered with traditional 'on-site' mixing. I have made my own chemical fix using car body filler and some dry sand. Everbuilds Anchorset Green 150 or Green 300 are classic examples of a styrene free product providing a chemical resistant finish. If you proceed further with the navigation, please confirm the Cookies usage. Call us on 01626 872886 for Free Advice. Making sure the specified anchor is then obtained and installed by a trained installer should make sure the application benefits from the Pros and doesnt suffer from the Cons. way out. Chemical anchors are usually based on a two part product, combining a resin and hardener packed together in the required ratio to provide rapid curing (usually 10 parts resin to one part hardener). Thixo Rapid - 310cc - fits I frequently see resin anchors (and self-tappers and undercuts) referred to in brochures and on websites as being stress free fixings which can be placed close to edges and to each other. If you need help with any type of Epoxy or Polyester Resin anchor, filler or coating problem Property Repair Systems will be pleased to give you completely free, no obligation advice on 01626 872 650. Additional electricity needs are supplemented by EDF . Epoxy Acrylate/Vinylester, Polyester and Pure Epoxy, Styrene-free Epoxy skeleton gun, 5. cartridges are used within the building and construction industry to apply skeleton gun, 3. These resin anchors will take massive loads, but preparation is important. The fixing methods above are quite traditional but there are alternative solutions. For the purposes of this project we will show you how to use chemical fixings or resin anchors as they are sometimes known.Gate hinge chemically fixed, Four easy stages complete this operation and all tools and materials are available atwww.epoxy-info.co.uk. A typical capsule anchor will take between 4 hours at -5C and 10 minutes at +20C (base material temperature). I Privacy The real usefulness is clear when trying to anchor fittings into loose stone walls and soft red bricks. Epoxy/Glass bar or Carbon Rod. For instance, if you have a 14 mm diameter Pintel you will need to drill a 16mm hole or create a 16mm slot, The reason we need to drill a larger hole or slot for the pintel or ironmongery in use is that we must allow room for the chemical fix adhesive to Bond. Unlike with expanding bolts that you can undo do and remove. The earliest type of resin anchor (introduced into the UK in 1970 from Germany) carried all the chemical components (resin, aggregate and catalyst) within a capsule originally of glass now sometimes of less fragile foil. The Cheap drill has an impact that is too short and more of a vibration than the SDS. I would use a 16mm sds masonry drill and drill 2 holes. supplied in 310cc tubes. our professional standard skeleton The closest mechanical anchors get to this degree of flexibility is that many types of throughbolt are available in a variety of lengths catering not just for different fixture thicknesses, but for different embedment depths and therefore loads as well. This sideways motion will put some strain on your drill so dont use excessive force. of the main substrate. Chemical anchors (I prefer the simpler term resin anchors) exert no setting stresses in the base material so can be specified at closer edge and spacing distances in concrete and will usually develop the strongest anchorage in masonry materials which are their main Pros. I believe so much in the chemical fix for the mounting of pretty much any heavy item into a stone or brick wall but I dont even say it any other form of mounting. They are much more sensitive to poor hole cleaning than mechanical anchors and must be allowed to cure before they can be tightened or loaded. The expansion force is too much for most man-made bricks. The beauty is that chemical fix resin type bonding agents is that the chemical fix not only sticks to the sides of the hole but locks behind the stone or brick. The chemical fix is actually just a polyester resin with an aggregate. Name takes you directly to the Shopping Page, or

At this point its also worth differentiating between different types of chemical anchors. Your email address will not be published. resistance to weathering.

acid cement resistant sulpher The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user. Chemical fixings are the fixing solution for transferring extreme loads in concrete, aerated concrete or masonry expansion-free.

Sitemap 7

We use an SDS type drill to drill a hole or create a slot. Polyester 380P - concentric But before I expand on that I want to segregate mechanical anchors into two categories: Expansion anchors and non-expansion anchors. Plastic Rawlplugs is only good if the wall is firm and in good condition. An injection resin of the same basic resin may take typically four times as long. The flexibility in resin anchor selection referred to above comes from the scope to design the anchor to use a bond length between 4 and 20 times the anchor diameter (this is best facilitated by injection systems) and to specify a different rod strength. within the internationally recognised ISO 9001:2000 Quality System. Versatility - Our systems can Mark Salmon, Independent Fixing Consultants. in high chemical and vibration resistance of the anchor and resin. anchor chemicals, in cartridge tubes for nozzle mixing. systems put minimal stress on the main substrate allowing anchors to be The problem with any chemical anchor is that when it hardens you cannot adjust it anymore. Set the tape at a distance from the tube end to allow for the resin that will be displaced by the bar.

We use an SDS type drill to drill a hole or create a slot. Polyester 380P - concentric But before I expand on that I want to segregate mechanical anchors into two categories: Expansion anchors and non-expansion anchors. Plastic Rawlplugs is only good if the wall is firm and in good condition. An injection resin of the same basic resin may take typically four times as long. The flexibility in resin anchor selection referred to above comes from the scope to design the anchor to use a bond length between 4 and 20 times the anchor diameter (this is best facilitated by injection systems) and to specify a different rod strength. within the internationally recognised ISO 9001:2000 Quality System. Versatility - Our systems can Mark Salmon, Independent Fixing Consultants. in high chemical and vibration resistance of the anchor and resin. anchor chemicals, in cartridge tubes for nozzle mixing. systems put minimal stress on the main substrate allowing anchors to be The problem with any chemical anchor is that when it hardens you cannot adjust it anymore. Set the tape at a distance from the tube end to allow for the resin that will be displaced by the bar.  Screw on the supplied which has the spiral mix up inside. (Hons. Long-life - All the cartridges Inject gently, slowly removing the tube from the hole, to deposit resin without trapping air. BULK DISCOUNTS The information you need may be in the Project below, but if not call them for expert, unbiased assistance with building products. One above and one below I Whittle the material away with the SDS drill at an angle toshing the bit. Don't fancy doing this project yourself? However, best practice has, until recently, dictated that holes for resin anchors should always be thoroughly cleaned out using a process of both blowing (or vacuuming), brushing and blowing. Disadvantages of using chemical fix instead of expanding bolts. skeleton gun. down machinery, Benefits of using Resins Clicking on a blue Product We love feedback on our DIY tutorials it helps us to make them the best they possibly can be so if you have any comments you would like to share with us, click the button below and let us know. masonry, * Holding down bolts for steel I find chemical fix such a practical solution for the mounting of the shutter hinge pins or pintels. Getting ready to use chemical fix for the securing of shutter pintles or other things you want to fix into a wall is easy.

Screw on the supplied which has the spiral mix up inside. (Hons. Long-life - All the cartridges Inject gently, slowly removing the tube from the hole, to deposit resin without trapping air. BULK DISCOUNTS The information you need may be in the Project below, but if not call them for expert, unbiased assistance with building products. One above and one below I Whittle the material away with the SDS drill at an angle toshing the bit. Don't fancy doing this project yourself? However, best practice has, until recently, dictated that holes for resin anchors should always be thoroughly cleaned out using a process of both blowing (or vacuuming), brushing and blowing. Disadvantages of using chemical fix instead of expanding bolts. skeleton gun. down machinery, Benefits of using Resins Clicking on a blue Product We love feedback on our DIY tutorials it helps us to make them the best they possibly can be so if you have any comments you would like to share with us, click the button below and let us know. masonry, * Holding down bolts for steel I find chemical fix such a practical solution for the mounting of the shutter hinge pins or pintels. Getting ready to use chemical fix for the securing of shutter pintles or other things you want to fix into a wall is easy.  Working ethically is important to us. When using a chemical fix adhesive you are required how to drill a hole larger than the metal object us to fix into it. to Site Home Page and Indexes, E: Mail us help@propertyrepairsystems.co.uk, David Moore, B.A. Home > DIY How To Projects and Tutorial Guides > How to Use Chemical Fixings and Resin Anchors, This project is sponsored by Property Repair Systems. side dual piston skeleton gun, 6. Our anchor adhesives can be provided as epoxy anchor or polyester Convenience - Our systems avoid Next Day Delivery - Nationally, by T.N.T. The gun is the same as you would use with silicone mastic stuff that you would seal your bath with. Drill an oversized hole You will find that you will need to stock less variety. Like silicone mastic you just need to remove the end of the tube and insert into a mastic gun one. skeleton gun, 4. - mixes in the nozzle, mix Signing up to fastenerandfixing.com enables you to manage your account details. Some manufacturers have developed faster curing systems bringing curing times for capsules (for use with special anchor rods in cracked concrete) down to as little as a matter of minutes and injection systems, for general purpose anchoring, to half the standard times while still being slower than standard capsules. dual piston skeleton gun. This is misleading. The wood we use is certified by PEFC . The curing time is the other bugbear of resin anchors whereas mechanical anchors may be loaded immediately. Chemical versus mechanical anchors the pros and cons. For many years I have used chemical fix. These expanding bolts have been available for years. But what are the downsides? The ability of resin anchors to bond with the irregular shape of the drilled hole means they transfer the load very effectively along the full length of the bond using bond strengths that modern formulations have increased dramatically in recent years. in a side by side twin cartridge, with spiral mixing nozzle, * Polyester The cage type will do just fine. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned. Let us help you find a tradesman local to you. They have special characteristics for uses like rebar anchoring, which justify having to wait this long. wire steel stainless cable balustrade trellis systems garden railing system s3i How To Use Bolts And Threaded Bars With Chemical Fixings For Heavy Duty Jobs, How To Use The Right Size Screw For Fixing, Types Of Screw For Different Uses - What Type Of Screw Should Be Used For What Kind Of Job Or Material Being Screwed. These were, and still are, very effective in concrete, but they dont work too well in masonry materials where resin can be lost in the voids caused by frogs (the V shaped depression in some bricks), in perforations and in the empty gaps between the leaves of solid brickwork. Single cartridge tube no hand mixing required two resins inside in a plastic bag fits standard skeleton guns resins mix in the nozzle, inside a spiral, which is replaced if the resin hardens before the tube is exhausted. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. These are rarely used and, in my opinion there is always something better, so, with limited space for this article, I will restrict my discussion to the spin-in type. If you have an old vacuum cleaner handy this can also work well.Injecting Resin Using Skeleton GunFloor Boards Removed. But it is the increased flexibility in the selection of resin anchors that has meant that, in most applications where loads need to be transferred into restricted sections of concrete or via a base plate of restricted dimensions, a resin system will provide a solution where a mechanical anchor, either expansion or undercut, just wont. The brushing bit removes the dust sticking to the sides of the hole. Chemical Fix is a polyester resin. Click here to go to our Shopping Pages. Each system is manufactured Injection Resin Slow Set, 1:1 side by Experience using this anchoring solution was in London East Barnet to be exact. In fact, the mixing of the two parts required for a chemical fix is done in the nozzle. It was surprising how tight you could tighten a nut. Whilst self-tapping screw anchors also introduce much lower stresses into the base material during installation and can be very strong in concrete, and work well in masonry, they dont offer such high strengths as chemical anchors and are best suited to temporary or short term applications. This Red plug is ideal for 4mm 4.5mm & 5mm diameter screws. One approach that safely avoids the need for separate hole cleaning operations is the adoption, by some manufacturers, of hollow drill bits which, when attached to a vacuum, will suck the dust from the hole as it is generated. - nozzle mixing means correct Resistance - Our systems result This is where chemical fixing can be a good choice. The Forgefix Resin injection system offers an easy fixing capability for numerous applications.

Working ethically is important to us. When using a chemical fix adhesive you are required how to drill a hole larger than the metal object us to fix into it. to Site Home Page and Indexes, E: Mail us help@propertyrepairsystems.co.uk, David Moore, B.A. Home > DIY How To Projects and Tutorial Guides > How to Use Chemical Fixings and Resin Anchors, This project is sponsored by Property Repair Systems. side dual piston skeleton gun, 6. Our anchor adhesives can be provided as epoxy anchor or polyester Convenience - Our systems avoid Next Day Delivery - Nationally, by T.N.T. The gun is the same as you would use with silicone mastic stuff that you would seal your bath with. Drill an oversized hole You will find that you will need to stock less variety. Like silicone mastic you just need to remove the end of the tube and insert into a mastic gun one. skeleton gun, 4. - mixes in the nozzle, mix Signing up to fastenerandfixing.com enables you to manage your account details. Some manufacturers have developed faster curing systems bringing curing times for capsules (for use with special anchor rods in cracked concrete) down to as little as a matter of minutes and injection systems, for general purpose anchoring, to half the standard times while still being slower than standard capsules. dual piston skeleton gun. This is misleading. The wood we use is certified by PEFC . The curing time is the other bugbear of resin anchors whereas mechanical anchors may be loaded immediately. Chemical versus mechanical anchors the pros and cons. For many years I have used chemical fix. These expanding bolts have been available for years. But what are the downsides? The ability of resin anchors to bond with the irregular shape of the drilled hole means they transfer the load very effectively along the full length of the bond using bond strengths that modern formulations have increased dramatically in recent years. in a side by side twin cartridge, with spiral mixing nozzle, * Polyester The cage type will do just fine. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned. Let us help you find a tradesman local to you. They have special characteristics for uses like rebar anchoring, which justify having to wait this long. wire steel stainless cable balustrade trellis systems garden railing system s3i How To Use Bolts And Threaded Bars With Chemical Fixings For Heavy Duty Jobs, How To Use The Right Size Screw For Fixing, Types Of Screw For Different Uses - What Type Of Screw Should Be Used For What Kind Of Job Or Material Being Screwed. These were, and still are, very effective in concrete, but they dont work too well in masonry materials where resin can be lost in the voids caused by frogs (the V shaped depression in some bricks), in perforations and in the empty gaps between the leaves of solid brickwork. Single cartridge tube no hand mixing required two resins inside in a plastic bag fits standard skeleton guns resins mix in the nozzle, inside a spiral, which is replaced if the resin hardens before the tube is exhausted. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. These are rarely used and, in my opinion there is always something better, so, with limited space for this article, I will restrict my discussion to the spin-in type. If you have an old vacuum cleaner handy this can also work well.Injecting Resin Using Skeleton GunFloor Boards Removed. But it is the increased flexibility in the selection of resin anchors that has meant that, in most applications where loads need to be transferred into restricted sections of concrete or via a base plate of restricted dimensions, a resin system will provide a solution where a mechanical anchor, either expansion or undercut, just wont. The brushing bit removes the dust sticking to the sides of the hole. Chemical Fix is a polyester resin. Click here to go to our Shopping Pages. Each system is manufactured Injection Resin Slow Set, 1:1 side by Experience using this anchoring solution was in London East Barnet to be exact. In fact, the mixing of the two parts required for a chemical fix is done in the nozzle. It was surprising how tight you could tighten a nut. Whilst self-tapping screw anchors also introduce much lower stresses into the base material during installation and can be very strong in concrete, and work well in masonry, they dont offer such high strengths as chemical anchors and are best suited to temporary or short term applications. This Red plug is ideal for 4mm 4.5mm & 5mm diameter screws. One approach that safely avoids the need for separate hole cleaning operations is the adoption, by some manufacturers, of hollow drill bits which, when attached to a vacuum, will suck the dust from the hole as it is generated. - nozzle mixing means correct Resistance - Our systems result This is where chemical fixing can be a good choice. The Forgefix Resin injection system offers an easy fixing capability for numerous applications.  We supply spare spiral mixers. columns, * Tying back existing masonry A more convenient and easier to use packaging format, available on some anchorset products, is the twin bag system, where the contents are contained in two separate polythene bags in a one piece cartridge that allows application using a standard sealant cartridge gun; and also provides a much easier flow. We stock a range of bolts, SDS or Special Direct System was developed by Hilti and Bosch in 1975. They may be stress free during installation but as soon as you use them to transfer a load into the base material it becomes stressed. Reliability - Accurate 'self-mixing' This SDS uses the drill bit design to produces a long stroke impact. I have seen these expanding bolts used in brick or stone walls but these expanding bolts tend to split the brick. or chemical anchor resins, are used to secure anchor bolts, starter bars, The mixing of the hardener and the resin is done in the novel and this does not happen until you apply pressure to the handle of the mastic gun. Undercut anchors as such dont work well in masonry so must be considered for concrete only. Theres only one real problem with mechanical anchors, without which there might be no need for chemical anchors. Shop | Technical | References, Return THIXO RAPID ANCHOR RESIN is high loads into slim columns, * Fixing sanitary-ware to hollow Capsule systems have always been less sensitive than injection systems to poor hole cleaning as the spinning action, together with the chunky aggregate, tends to draw some of the dust left on the sides of the hole into the mix, whereas injection systems simply lay the resin against any dust left behind. Take the stud in the gloved hand and slowly rotate whilst pushing it into the resin filled hole. system for guaranteed quality. surfaces together. the problems encountered with traditional 'on-site' mixing. I have made my own chemical fix using car body filler and some dry sand. Everbuilds Anchorset Green 150 or Green 300 are classic examples of a styrene free product providing a chemical resistant finish. If you proceed further with the navigation, please confirm the Cookies usage. Call us on 01626 872886 for Free Advice. Making sure the specified anchor is then obtained and installed by a trained installer should make sure the application benefits from the Pros and doesnt suffer from the Cons. way out. Chemical anchors are usually based on a two part product, combining a resin and hardener packed together in the required ratio to provide rapid curing (usually 10 parts resin to one part hardener). Thixo Rapid - 310cc - fits I frequently see resin anchors (and self-tappers and undercuts) referred to in brochures and on websites as being stress free fixings which can be placed close to edges and to each other. If you need help with any type of Epoxy or Polyester Resin anchor, filler or coating problem Property Repair Systems will be pleased to give you completely free, no obligation advice on 01626 872 650. Additional electricity needs are supplemented by EDF . Epoxy Acrylate/Vinylester, Polyester and Pure Epoxy, Styrene-free Epoxy skeleton gun, 5. cartridges are used within the building and construction industry to apply skeleton gun, 3. These resin anchors will take massive loads, but preparation is important. The fixing methods above are quite traditional but there are alternative solutions. For the purposes of this project we will show you how to use chemical fixings or resin anchors as they are sometimes known.Gate hinge chemically fixed, Four easy stages complete this operation and all tools and materials are available atwww.epoxy-info.co.uk. A typical capsule anchor will take between 4 hours at -5C and 10 minutes at +20C (base material temperature). I Privacy The real usefulness is clear when trying to anchor fittings into loose stone walls and soft red bricks. Epoxy/Glass bar or Carbon Rod. For instance, if you have a 14 mm diameter Pintel you will need to drill a 16mm hole or create a 16mm slot, The reason we need to drill a larger hole or slot for the pintel or ironmongery in use is that we must allow room for the chemical fix adhesive to Bond. Unlike with expanding bolts that you can undo do and remove. The earliest type of resin anchor (introduced into the UK in 1970 from Germany) carried all the chemical components (resin, aggregate and catalyst) within a capsule originally of glass now sometimes of less fragile foil. The Cheap drill has an impact that is too short and more of a vibration than the SDS. I would use a 16mm sds masonry drill and drill 2 holes. supplied in 310cc tubes. our professional standard skeleton The closest mechanical anchors get to this degree of flexibility is that many types of throughbolt are available in a variety of lengths catering not just for different fixture thicknesses, but for different embedment depths and therefore loads as well. This sideways motion will put some strain on your drill so dont use excessive force. of the main substrate. Chemical anchors (I prefer the simpler term resin anchors) exert no setting stresses in the base material so can be specified at closer edge and spacing distances in concrete and will usually develop the strongest anchorage in masonry materials which are their main Pros. I believe so much in the chemical fix for the mounting of pretty much any heavy item into a stone or brick wall but I dont even say it any other form of mounting. They are much more sensitive to poor hole cleaning than mechanical anchors and must be allowed to cure before they can be tightened or loaded. The expansion force is too much for most man-made bricks. The beauty is that chemical fix resin type bonding agents is that the chemical fix not only sticks to the sides of the hole but locks behind the stone or brick. The chemical fix is actually just a polyester resin with an aggregate. Name takes you directly to the Shopping Page, or

We supply spare spiral mixers. columns, * Tying back existing masonry A more convenient and easier to use packaging format, available on some anchorset products, is the twin bag system, where the contents are contained in two separate polythene bags in a one piece cartridge that allows application using a standard sealant cartridge gun; and also provides a much easier flow. We stock a range of bolts, SDS or Special Direct System was developed by Hilti and Bosch in 1975. They may be stress free during installation but as soon as you use them to transfer a load into the base material it becomes stressed. Reliability - Accurate 'self-mixing' This SDS uses the drill bit design to produces a long stroke impact. I have seen these expanding bolts used in brick or stone walls but these expanding bolts tend to split the brick. or chemical anchor resins, are used to secure anchor bolts, starter bars, The mixing of the hardener and the resin is done in the novel and this does not happen until you apply pressure to the handle of the mastic gun. Undercut anchors as such dont work well in masonry so must be considered for concrete only. Theres only one real problem with mechanical anchors, without which there might be no need for chemical anchors. Shop | Technical | References, Return THIXO RAPID ANCHOR RESIN is high loads into slim columns, * Fixing sanitary-ware to hollow Capsule systems have always been less sensitive than injection systems to poor hole cleaning as the spinning action, together with the chunky aggregate, tends to draw some of the dust left on the sides of the hole into the mix, whereas injection systems simply lay the resin against any dust left behind. Take the stud in the gloved hand and slowly rotate whilst pushing it into the resin filled hole. system for guaranteed quality. surfaces together. the problems encountered with traditional 'on-site' mixing. I have made my own chemical fix using car body filler and some dry sand. Everbuilds Anchorset Green 150 or Green 300 are classic examples of a styrene free product providing a chemical resistant finish. If you proceed further with the navigation, please confirm the Cookies usage. Call us on 01626 872886 for Free Advice. Making sure the specified anchor is then obtained and installed by a trained installer should make sure the application benefits from the Pros and doesnt suffer from the Cons. way out. Chemical anchors are usually based on a two part product, combining a resin and hardener packed together in the required ratio to provide rapid curing (usually 10 parts resin to one part hardener). Thixo Rapid - 310cc - fits I frequently see resin anchors (and self-tappers and undercuts) referred to in brochures and on websites as being stress free fixings which can be placed close to edges and to each other. If you need help with any type of Epoxy or Polyester Resin anchor, filler or coating problem Property Repair Systems will be pleased to give you completely free, no obligation advice on 01626 872 650. Additional electricity needs are supplemented by EDF . Epoxy Acrylate/Vinylester, Polyester and Pure Epoxy, Styrene-free Epoxy skeleton gun, 5. cartridges are used within the building and construction industry to apply skeleton gun, 3. These resin anchors will take massive loads, but preparation is important. The fixing methods above are quite traditional but there are alternative solutions. For the purposes of this project we will show you how to use chemical fixings or resin anchors as they are sometimes known.Gate hinge chemically fixed, Four easy stages complete this operation and all tools and materials are available atwww.epoxy-info.co.uk. A typical capsule anchor will take between 4 hours at -5C and 10 minutes at +20C (base material temperature). I Privacy The real usefulness is clear when trying to anchor fittings into loose stone walls and soft red bricks. Epoxy/Glass bar or Carbon Rod. For instance, if you have a 14 mm diameter Pintel you will need to drill a 16mm hole or create a 16mm slot, The reason we need to drill a larger hole or slot for the pintel or ironmongery in use is that we must allow room for the chemical fix adhesive to Bond. Unlike with expanding bolts that you can undo do and remove. The earliest type of resin anchor (introduced into the UK in 1970 from Germany) carried all the chemical components (resin, aggregate and catalyst) within a capsule originally of glass now sometimes of less fragile foil. The Cheap drill has an impact that is too short and more of a vibration than the SDS. I would use a 16mm sds masonry drill and drill 2 holes. supplied in 310cc tubes. our professional standard skeleton The closest mechanical anchors get to this degree of flexibility is that many types of throughbolt are available in a variety of lengths catering not just for different fixture thicknesses, but for different embedment depths and therefore loads as well. This sideways motion will put some strain on your drill so dont use excessive force. of the main substrate. Chemical anchors (I prefer the simpler term resin anchors) exert no setting stresses in the base material so can be specified at closer edge and spacing distances in concrete and will usually develop the strongest anchorage in masonry materials which are their main Pros. I believe so much in the chemical fix for the mounting of pretty much any heavy item into a stone or brick wall but I dont even say it any other form of mounting. They are much more sensitive to poor hole cleaning than mechanical anchors and must be allowed to cure before they can be tightened or loaded. The expansion force is too much for most man-made bricks. The beauty is that chemical fix resin type bonding agents is that the chemical fix not only sticks to the sides of the hole but locks behind the stone or brick. The chemical fix is actually just a polyester resin with an aggregate. Name takes you directly to the Shopping Page, or  At this point its also worth differentiating between different types of chemical anchors. Your email address will not be published. resistance to weathering. acid cement resistant sulpher The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user. Chemical fixings are the fixing solution for transferring extreme loads in concrete, aerated concrete or masonry expansion-free.

At this point its also worth differentiating between different types of chemical anchors. Your email address will not be published. resistance to weathering. acid cement resistant sulpher The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user. Chemical fixings are the fixing solution for transferring extreme loads in concrete, aerated concrete or masonry expansion-free.