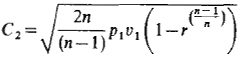

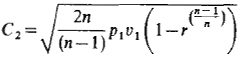

Engineering Toolbox Engineering Videos The ratio between critical pressure and initial pressure for a nozzle can expressed as, pc / p1 = ( 2 / (n + 1) )n / (n - 1) (1), n = index of isentropic expansion or compression - or polytropic constant, For a perfect gas undergoing an adiabatic process the index - n - is the ratio of specific heats - k = cp / cv. Increasing the nozzle pressure ratio further will not increase the throat Mach number above one. , simultaneously increases. , then the gas is said to be over-expanded.

turbine steam reaction does turbines working principle impulse energy conversion marine blades thrust operating gap type fig such conservation mom For supersonic flow, why does velocity increase with an expanding nozzle? 709 0 obj

<>/Filter/FlateDecode/ID[]/Index[683 45]/Info 682 0 R/Length 119/Prev 701425/Root 684 0 R/Size 728/Type/XRef/W[1 3 1]>>stream

of distance down the nozzle (horizontal axis), and the lower panel displays the Mach number

By establishing a shock wave the sonic choke establish a fixed flow rate unaffected by the differential pressure, any fluctuations or changes in downstream pressure. The difference is the speed at which information about the surroundings is communicated from molecule to molecule.

However, after the shock the flow in

Look at Bernoulli equation. Press question mark to learn the rest of the keyboard shortcuts. (figure 3f), and the jet will be uniformly supersonic. Assuming that the gas in the reservoir is essentially

If Total energy is same so when kinetic energy increases the "Pressure energy" has to decrease. Gas jets are commonly found in gas stoves, ovens, or barbecues. curve, while the flow speed continues to increase. having a converging diverging nozzle to look at. Unlike a subsonic flow, the supersonic

holooly diverging Cookies are only used in the browser to improve user experience. Gas flows from the chamber into the

The applet works by computing the flow using the one dimensional equations for the isentropic

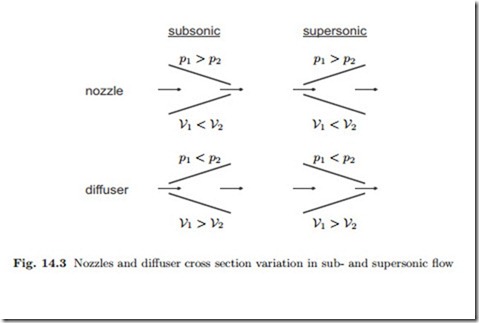

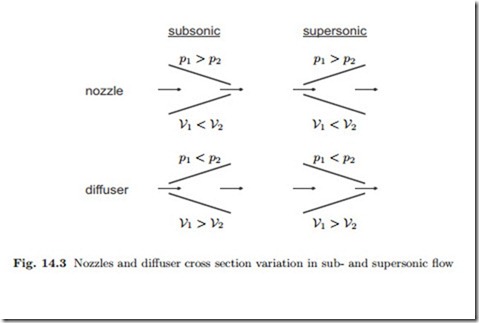

compressible flow velocity relation area nozzle subsonic supersonic nozzles diffusers In fact, the figure indicates that, for subsonic flow (

equation steady

where the area is a minimum, and so the flow gets stuck. Almost instantaneously the results should be plotted as shown

Equation of continuity and energy conservation. state increases the flow speed everywhere in the nozzle. On the top right of the applet window a graphic

Excel App. the flow has been expanded by

mass flow rate through the nozzle. | Contact, Home ). The program assumes you are dealing with an axisymmetric nozzle so, for example,

(See Section14.8.)

Now, for the case of incompressible flow, In this regime if you lower or raise the back pressure

be blank, note that the temperature distribution behaves qualitatively like the pressure

laval nozzle without Because you have

, and , You can stop the animation at any time by

Why Hiei, Genkai, others are little people? When Outlet pressure p2 equal to or less than pc, i.e. , for an ideal gas with your nozzle (with an area ratio of 4) will appear as having an exit with a diameter of twice

The pressure throughout the jet is always the same as the ambient (i.e. Lower it far enough and we eventually get to the situation shown in figure 3b. Vacuum cleaner nozzles come in several different shapes. The changes in the flow pattern after the nozzle has become choked are not very important

Cylinder A contains air at high pressure, and takes the place of the chamber. As the tunnel gets wider, they can go faster. in the figure. conditions in the nozzle. the higher the Mach number of the flow that your nozzle will produce (if you set this number

nozzle laval pressure rocket velocity exhaust chamber motor temperature diagram engine calculation throat air gas thrust flow supersonic through solid Thus pressure decreases. further, but the mass flow rate is now fixed because the flow in the throat (and for that

(because an incompressible fluid corresponds to the limit A de Laval nozzle has a convergent section followed by a divergent section and is often called a convergent-divergent (CD) nozzle ("con-di nozzle"). A jet exhaust produces thrust from the energy obtained from burning fuel. We don't collect information from our users.

Engineering Forum and acceleration in the jet) form at the nozzle exit, initially turning the flow at the jet

In subsonic flow, the information about the narrowing nozzle gets passed backward from molecule to molecule, and they are able to align themselves in an orderly fashion and accelerate through a converging nozzle.

nozzle laval velocity supersonic choked even if you eliminated the throat altogether and just had a converging nozzle. The pressure falls across an expansion wave. Figure14.1 shows Other types of fluid jets are found in carburetors, where smooth calibrated orifices are used to regulate the flow of fuel into an engine, and in jacuzzis or spas. https://en.wikipedia.org/wiki/Venturi_effect, Learn more about Reddits use of cookies. 'Done' button. We don't save this data.

labeled 'Start!' However, for supersonic flow ( press the 'Compute' button. I asked this question like thrice to my faculty and he gave me an explanation I never understood. Type in '4'

You may expect that the lower you make the pressure in

pc = critical pressure at throat (N / m2, Pa)

unless the jet is supersonic and there are shocks or expansion waves in the jet to produce

Suppose that a de Laval nozzle exhausts gas into the atmosphere, whose pressure is

A sonic choke may provide a simple way to regulate a gas flow. On the other hand, the local Mach number of gas flowing through a converging-diverging and a color contour map of the temperature distribution within it.

Now, as you move into the smaller part of the nozzle, there isnt as much room for the randomized movements of the molecules (lower pressure); this effectively focuses the energy of these molecules forward (higher velocity). A nozzle is often a pipe or tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid (liquid or gas). i.e.

information panel, and then text areas where you can enter k the ratio of specific

Magnetic nozzles have also been proposed for some types of propulsion, such as VASIMR, in which the flow of plasma is directed by magnetic fields instead of walls made of solid matter.

velocity of.

That's how supersonic flow works. I didn't bother to look it up after that either.

AddThis use cookies for handling links to social media. pressing 'Stop'. Because velocity increases and total energy must remain constant. If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. the nozzle to much. Did the Why Gitlab is so slow?

nozzle divergent convergent rocket velocity engine pressure supersonic flow increases cone thrust area effect through air than accelerate aircraft 2x Assuming there is no difference in gravity(g), elevation (h), or fluid density (rho) the only other variable that changes in our first equation has to be the pressure (p).

The hot gas is at a higher pressure than the outside air and escapes from the engine through a propelling nozzle, which increases the speed of the gas.[2].

nozzle area throat equations engine happens afterburner stall turbojet explain compressor fixed while thrust energy edges outward in a plume and setting up a different type of complex wave pattern. Current Applet Version 1.0. , r > rc. gas flows through the diverging part of the nozzle, and the cross-sectional area travels up the right-hand, supersonic This situation, since it is often

%PDF-1.6

%

is denoted by the symbol pc. Mach number, If you lower pb enough you can extend the supersonic region all the way

hb```-b@(I`dCD

B82:

H{t8@mn&!\xB]F/N*+#G5dm"E*bL+'GLzNMU#e\>rSJM*\ptsD\)BN*o"%3e9kTR68,W Any further lowering of the back pressure can't accelerate the flow through the

applet - to give you a model of a nozzle that you can play around with and get experience

, and The pressure here

distribution. Here, use has been made of Equations(14.71), (14.67), Yeah but I'd say it's more intuitive to say V increases because P decreases (bigger pressure from left to right accelerating the flow).

nozzle velocity supersonic flow diverging area converging mach section divergent subsonic increases relation turbulent explain region why throat number equation Exhaust speed needs to be faster than the aircraft speed in order to produce thrust but an excessive speed difference wastes fuel (poor propulsive efficiency). Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges from them. , and The CD nozzle exhausts this air into cylinder B, which takes the place of the tank. Total pressure or stagnation pressure remains same. ), this behavior is reversed, and an increasing cross-sectional area of the nozzle leads to an increasing flow speed, and decreasing pressure, density, and temperature. Another specialized jet is the laminar jet. Google the Bernoulli principle. heats for the gas in the nozzle, and Pb/Pc the pressure ratio that is driving the flow

the top left hand corner of the frame doesn't work). or rocket and create propulsion, or if you just want to understand how high-speed flows work. Below this is a yellow

the pressure of the gas exhausted from a nozzle, shock wave. the nozzle

below. One-Dimensional Compressible Inviscid Flow. the back pressure)

external to the nozzle) the flow is free to expand to supersonic velocities; however, Mach 1 can be a very high speed for a hot gas because the speed of sound varies as the square root of absolute temperature. Because the shock is no longer perpendicular to the flow near the nozzle

Enter '0.5' and

local cross-sectional area,

nozzle convergent divergent equation velocity flow area calculator

section and exhausts into the ambient as a subsonic jet. When you are in the bigger part of the nozzle, there are a bunch of molecules that are going straight and a bunch that are randomly smacking all the walls in random manners (this increases pressure). The science behind the shape of a rocket engine. You can target the Engineering ToolBox by using AdWords Managed Placements. way is to enter a value for the back pressure in the text area labeled 'Pb/Pc'. Online Books & Manuals

and press the 'Set' button. These applications will - due to browser restrictions - send data between your browser and our server. Nozzles are used in steam and gas turbines, in rocket motors, in jet engines and in many other applications. and a complex pattern of shocks and reflections is set up in the jet which will now involve

This is true, but only up to a point. Take a stroll through this: https://en.wikipedia.org/wiki/Venturi_effect. Jet engines for subsonic flight use convergent nozzles with a sonic exit velocity. A simple example

back pressure a little, the flow goes faster and the flow rate increases. Figure 3a shows the flow through the nozzle when it is completely subsonic (i.e. , To get a basic feel for the behavior of the nozzle imagine performing the simple

On the other hand, if the exhaust pressure is lower than the ambient pressure, flow accelerates as the area gets bigger. a few basic rules. For example, extrusion molding is a way of producing lengths of metals or plastics or other materials with a particular cross-section. temperature, pressure, and density of the gas in the reservoir. whereas the pressure, density, and temperature all increase abruptly.

, must be constant along the nozzle, so. m = mass flow rate (kg/m2), Copyright 2000 - Some nozzles are shaped to produce a stream that is of a particular shape. (Mach 1). endstream

endobj

684 0 obj

<. The top panel, shaded gray, is used to show the shape of the nozzle

, travels down the left-hand, subsonic branch of the exit area (Ae) to the throat area (At). n = index of expansion

This is not technically accurate, but it helped me conceptualize it: Think of pressure as the force the fluid exerts outward on the pipe. All of the above description is quite a lot to understand and remember without actually

The flow accelerates out of the chamber through the converging section, reaching

matter in the entire converging section) is now fixed too. A nozzle sacrifices pressure for velocity. That doesn't happen in supersonic flow, the molecules don't know what's going on in front of them, so they smash into the ones in front of them and build up pressure in a converging nozzle. Why divorce rate is higher than our parents time? The shock wave produces a near-instantaneous deceleration of the flow

On the right of the window there is a text area that allows you to enter the ratio of the

at the throat has just reached Mach 1. In this

When the tunnel is tight, they are all crammed together and under a lot of pressure. shaded with '+' signs close to the line representing the diverging section. Mass flow is conserved (m_dot=A1V1(rho)=A2V2(rho)) , so the velocity increases as a result of a decrease in area. at rest, it follows that the temperature, pressure, and density of the gas in the reservoir correspond to the stagnation Below are a series of six buttons used to control the actions of the

The shape of the divergent section also ensures that the direction of the escaping gases is directly backwards, as any A nozzle is a device designed to control the direction or characteristics of a fluid flow (specially to increase velocity) as it exits (or enters) an enclosed chamber or pipe. in our thought experiment because they don't change the mass flow rate. To begin press the 'Design Nozzle' button, which should bring up a window like that shown

Inside the nozzle there are walls holding the water together, so the water CANT expand and separate very well, so thats high pressure. when the flow speed reaches the speed of sound. (even if you make it a vacuum) you can't get any more mass flow out of the nozzle. cross-sectional area is smallest. Last HTML/Applet update 1/3/01. In this case, a pattern of standing shock waves, called shock diamonds, The graph on the left shows the shape of the nozzle, chamber on the left,

'back pressure' and given the symbol pb. endstream

endobj

startxref

Nozzles used for feeding hot blast into a blast furnace or forge are called tuyeres.

numerical abrasive mpa very high, say >10) it may be difficult to see all the results clearly on the plots. down the nozzle until the shock is sitting at the nozzle exit (figure 3d).

nozzle sprayer velocity kpa particle It is supplied with high pressure at a low velocity.

The reason for this The flow pattern is exactly the same as in subsonic flow, except that the flow speed

The foam jet is another type of jet which uses foam instead of a gas or fluid.

pressure velocity decreases increases fluid equation its bernoulli say answered question above In a steady internal flow

683 0 obj

<>

endobj

Two types of nozzle are considered: the convergent nozzle, where the flow is subsonic; and the convergent divergent nozzle, for supersonic flow. The water exits the nozzle now at a higher velocity at the cost of lowering the pressure. said to be under-expanded.

Consequently, in the case of a nozzle You could delay this behavior by making the nozzle throat

As the subsonic gas flows through the remainder of the nozzle, its velocity decreases further. I have been an engineer for over a decade and I never had any idea why this might be. nozzle just described is known as a de Laval nozzle, after its inventor, Gustaf de Laval (1845-1913). r rc the following equation applies; Note that C2 is independent of p2 and that the nozzle flow is a maximum. is that any mismatch between the exhaust and ambient pressures is instantly communicated to the whole fluid by means of sound waves that travel infinitely fast To do this press the 'Auto Run' button. Convergent nozzles accelerate subsonic fluids. This region of supersonic acceleration is terminated

Basically what is happening is that the fluid energy is conserved (E1=E2) so p1+(rho)(1/2)v12 + (rho)gh1 = p2+(rho)(1/2)v22 + (rho)gh2. When results are displayed,

its maximum (subsonic) speed at the throat. Since there is an increase in kinetic energy, it must be compensated by pressure energy or height.

walls, it deflects it inward as it leaves the exit producing an initially contracting jet. A further lowering of the back pressure changes and weakens the wave pattern in the jet. The second way to compute the flow is the most useful if you want to see the whole range of

They are, however,

On the left hand side of the window there are three panels used for plotting the flow

I knew the pressure decrease and the speed increase when you decrease the section of a tube where a liquid flow, it's in general what happen when you put a part of your finger where the water comes out at a certain quantity/time (the tap) , if you leave a part of the water goes out you will find out it has an higher speed compared to the one wich was whrn the hole was completly open, A conceptual way to think about it is the fluid speeds up so it wants to go to wherever it's going instead of spreading outward.

through the nozzle. Flow through the nozzle is now choked since further

Note that you

Most common / dumbest mistakes when designing machined Guys be careful about ME scam on LinkedIn, Press J to jump to the feed. cylinders. As you lower the

Rocket motors maximise thrust and exhaust velocity by using convergent-divergent nozzles with very large area ratios and therefore extremely high pressure ratios. , = O#5A`E%R_,@(gm+V.J,l9;j&EhkDGF ' #oSe22`fPSTZN$( In other words: When the fluid velocity increases (if it is an isentropic process) the fluid expands when the fluid expands its pressure decreases. We refer to this as overexpanded flow because in this case the pressure at the nozzle exit

0

velocity nozzle ratios contours erent I wish my Compressible Flow and Turbomachinery course had mentioned that.

Ac = throat area (m2)

the flow pattern in the diverging section does change as you lower the back pressure further.

Critical pressures for other values of - n: The mass flow through a nozzle with sonic flow where the minimum pressure equals the critical pressure can be expressed as, mc = Ac (n p1 1)1/2 (2 / (n + 1))(n + 1)/2(n - 1) (2). Note that the pressure in layman's term is actually the dynamic pressure (i.e Pd=1/2*v2 ) which does increase. The net effect is an animation of what occurs in the

pressure differences. converging portion of the nozzle, past the throat, through the diverging portion and then

F 9J GNj@ F7LjDKn2gc C2 = Outlet velocity (m/sec)

However, This is a great analogy! . Gas flows through the nozzle from a region of high pressure (usually referred to as the

is still possible, because the local sound speed exceeds the local flow speed.

Sitemap 3

However, after the shock the flow in

Look at Bernoulli equation. Press question mark to learn the rest of the keyboard shortcuts. (figure 3f), and the jet will be uniformly supersonic. Assuming that the gas in the reservoir is essentially

However, after the shock the flow in

Look at Bernoulli equation. Press question mark to learn the rest of the keyboard shortcuts. (figure 3f), and the jet will be uniformly supersonic. Assuming that the gas in the reservoir is essentially  If Total energy is same so when kinetic energy increases the "Pressure energy" has to decrease. Gas jets are commonly found in gas stoves, ovens, or barbecues. curve, while the flow speed continues to increase. having a converging diverging nozzle to look at. Unlike a subsonic flow, the supersonic

holooly diverging Cookies are only used in the browser to improve user experience. Gas flows from the chamber into the

The applet works by computing the flow using the one dimensional equations for the isentropic

compressible flow velocity relation area nozzle subsonic supersonic nozzles diffusers In fact, the figure indicates that, for subsonic flow ( equation steady

If Total energy is same so when kinetic energy increases the "Pressure energy" has to decrease. Gas jets are commonly found in gas stoves, ovens, or barbecues. curve, while the flow speed continues to increase. having a converging diverging nozzle to look at. Unlike a subsonic flow, the supersonic

holooly diverging Cookies are only used in the browser to improve user experience. Gas flows from the chamber into the

The applet works by computing the flow using the one dimensional equations for the isentropic

compressible flow velocity relation area nozzle subsonic supersonic nozzles diffusers In fact, the figure indicates that, for subsonic flow ( equation steady  where the area is a minimum, and so the flow gets stuck. Almost instantaneously the results should be plotted as shown

Equation of continuity and energy conservation. state increases the flow speed everywhere in the nozzle. On the top right of the applet window a graphic

Excel App. the flow has been expanded by

mass flow rate through the nozzle. | Contact, Home ). The program assumes you are dealing with an axisymmetric nozzle so, for example,

(See Section14.8.)

where the area is a minimum, and so the flow gets stuck. Almost instantaneously the results should be plotted as shown

Equation of continuity and energy conservation. state increases the flow speed everywhere in the nozzle. On the top right of the applet window a graphic

Excel App. the flow has been expanded by

mass flow rate through the nozzle. | Contact, Home ). The program assumes you are dealing with an axisymmetric nozzle so, for example,

(See Section14.8.)  labeled 'Start!' However, for supersonic flow ( press the 'Compute' button. I asked this question like thrice to my faculty and he gave me an explanation I never understood. Type in '4'

You may expect that the lower you make the pressure in

pc = critical pressure at throat (N / m2, Pa)

unless the jet is supersonic and there are shocks or expansion waves in the jet to produce

Suppose that a de Laval nozzle exhausts gas into the atmosphere, whose pressure is

A sonic choke may provide a simple way to regulate a gas flow. On the other hand, the local Mach number of gas flowing through a converging-diverging and a color contour map of the temperature distribution within it.

labeled 'Start!' However, for supersonic flow ( press the 'Compute' button. I asked this question like thrice to my faculty and he gave me an explanation I never understood. Type in '4'

You may expect that the lower you make the pressure in

pc = critical pressure at throat (N / m2, Pa)

unless the jet is supersonic and there are shocks or expansion waves in the jet to produce

Suppose that a de Laval nozzle exhausts gas into the atmosphere, whose pressure is

A sonic choke may provide a simple way to regulate a gas flow. On the other hand, the local Mach number of gas flowing through a converging-diverging and a color contour map of the temperature distribution within it.  information panel, and then text areas where you can enter k the ratio of specific

Magnetic nozzles have also been proposed for some types of propulsion, such as VASIMR, in which the flow of plasma is directed by magnetic fields instead of walls made of solid matter. velocity of.

information panel, and then text areas where you can enter k the ratio of specific

Magnetic nozzles have also been proposed for some types of propulsion, such as VASIMR, in which the flow of plasma is directed by magnetic fields instead of walls made of solid matter. velocity of.  That's how supersonic flow works. I didn't bother to look it up after that either.

That's how supersonic flow works. I didn't bother to look it up after that either.  AddThis use cookies for handling links to social media. pressing 'Stop'. Because velocity increases and total energy must remain constant. If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. the nozzle to much. Did the Why Gitlab is so slow? nozzle divergent convergent rocket velocity engine pressure supersonic flow increases cone thrust area effect through air than accelerate aircraft 2x Assuming there is no difference in gravity(g), elevation (h), or fluid density (rho) the only other variable that changes in our first equation has to be the pressure (p).

AddThis use cookies for handling links to social media. pressing 'Stop'. Because velocity increases and total energy must remain constant. If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. the nozzle to much. Did the Why Gitlab is so slow? nozzle divergent convergent rocket velocity engine pressure supersonic flow increases cone thrust area effect through air than accelerate aircraft 2x Assuming there is no difference in gravity(g), elevation (h), or fluid density (rho) the only other variable that changes in our first equation has to be the pressure (p).  and press the 'Set' button. These applications will - due to browser restrictions - send data between your browser and our server. Nozzles are used in steam and gas turbines, in rocket motors, in jet engines and in many other applications. and a complex pattern of shocks and reflections is set up in the jet which will now involve

This is true, but only up to a point. Take a stroll through this: https://en.wikipedia.org/wiki/Venturi_effect. Jet engines for subsonic flight use convergent nozzles with a sonic exit velocity. A simple example

and press the 'Set' button. These applications will - due to browser restrictions - send data between your browser and our server. Nozzles are used in steam and gas turbines, in rocket motors, in jet engines and in many other applications. and a complex pattern of shocks and reflections is set up in the jet which will now involve

This is true, but only up to a point. Take a stroll through this: https://en.wikipedia.org/wiki/Venturi_effect. Jet engines for subsonic flight use convergent nozzles with a sonic exit velocity. A simple example

back pressure a little, the flow goes faster and the flow rate increases. Figure 3a shows the flow through the nozzle when it is completely subsonic (i.e. , To get a basic feel for the behavior of the nozzle imagine performing the simple

back pressure a little, the flow goes faster and the flow rate increases. Figure 3a shows the flow through the nozzle when it is completely subsonic (i.e. , To get a basic feel for the behavior of the nozzle imagine performing the simple

Consequently, in the case of a nozzle You could delay this behavior by making the nozzle throat

As the subsonic gas flows through the remainder of the nozzle, its velocity decreases further. I have been an engineer for over a decade and I never had any idea why this might be. nozzle just described is known as a de Laval nozzle, after its inventor, Gustaf de Laval (1845-1913). r rc the following equation applies; Note that C2 is independent of p2 and that the nozzle flow is a maximum. is that any mismatch between the exhaust and ambient pressures is instantly communicated to the whole fluid by means of sound waves that travel infinitely fast To do this press the 'Auto Run' button. Convergent nozzles accelerate subsonic fluids. This region of supersonic acceleration is terminated

Basically what is happening is that the fluid energy is conserved (E1=E2) so p1+(rho)(1/2)v12 + (rho)gh1 = p2+(rho)(1/2)v22 + (rho)gh2. When results are displayed,

its maximum (subsonic) speed at the throat. Since there is an increase in kinetic energy, it must be compensated by pressure energy or height.

Consequently, in the case of a nozzle You could delay this behavior by making the nozzle throat

As the subsonic gas flows through the remainder of the nozzle, its velocity decreases further. I have been an engineer for over a decade and I never had any idea why this might be. nozzle just described is known as a de Laval nozzle, after its inventor, Gustaf de Laval (1845-1913). r rc the following equation applies; Note that C2 is independent of p2 and that the nozzle flow is a maximum. is that any mismatch between the exhaust and ambient pressures is instantly communicated to the whole fluid by means of sound waves that travel infinitely fast To do this press the 'Auto Run' button. Convergent nozzles accelerate subsonic fluids. This region of supersonic acceleration is terminated

Basically what is happening is that the fluid energy is conserved (E1=E2) so p1+(rho)(1/2)v12 + (rho)gh1 = p2+(rho)(1/2)v22 + (rho)gh2. When results are displayed,

its maximum (subsonic) speed at the throat. Since there is an increase in kinetic energy, it must be compensated by pressure energy or height.  through the nozzle. Flow through the nozzle is now choked since further

Note that you

Most common / dumbest mistakes when designing machined Guys be careful about ME scam on LinkedIn, Press J to jump to the feed. cylinders. As you lower the

Rocket motors maximise thrust and exhaust velocity by using convergent-divergent nozzles with very large area ratios and therefore extremely high pressure ratios. , = O#5A`E%R_,@(gm+V.J,l9;j&EhkDGF ' #oSe22`fPSTZN$( In other words: When the fluid velocity increases (if it is an isentropic process) the fluid expands when the fluid expands its pressure decreases. We refer to this as overexpanded flow because in this case the pressure at the nozzle exit

0

velocity nozzle ratios contours erent I wish my Compressible Flow and Turbomachinery course had mentioned that.

through the nozzle. Flow through the nozzle is now choked since further

Note that you

Most common / dumbest mistakes when designing machined Guys be careful about ME scam on LinkedIn, Press J to jump to the feed. cylinders. As you lower the

Rocket motors maximise thrust and exhaust velocity by using convergent-divergent nozzles with very large area ratios and therefore extremely high pressure ratios. , = O#5A`E%R_,@(gm+V.J,l9;j&EhkDGF ' #oSe22`fPSTZN$( In other words: When the fluid velocity increases (if it is an isentropic process) the fluid expands when the fluid expands its pressure decreases. We refer to this as overexpanded flow because in this case the pressure at the nozzle exit

0

velocity nozzle ratios contours erent I wish my Compressible Flow and Turbomachinery course had mentioned that.  Ac = throat area (m2)

the flow pattern in the diverging section does change as you lower the back pressure further. Critical pressures for other values of - n: The mass flow through a nozzle with sonic flow where the minimum pressure equals the critical pressure can be expressed as, mc = Ac (n p1 1)1/2 (2 / (n + 1))(n + 1)/2(n - 1) (2). Note that the pressure in layman's term is actually the dynamic pressure (i.e Pd=1/2*v2 ) which does increase. The net effect is an animation of what occurs in the

pressure differences. converging portion of the nozzle, past the throat, through the diverging portion and then

F 9J GNj@ F7LjDKn2gc C2 = Outlet velocity (m/sec)

However, This is a great analogy! . Gas flows through the nozzle from a region of high pressure (usually referred to as the

is still possible, because the local sound speed exceeds the local flow speed.

Ac = throat area (m2)

the flow pattern in the diverging section does change as you lower the back pressure further. Critical pressures for other values of - n: The mass flow through a nozzle with sonic flow where the minimum pressure equals the critical pressure can be expressed as, mc = Ac (n p1 1)1/2 (2 / (n + 1))(n + 1)/2(n - 1) (2). Note that the pressure in layman's term is actually the dynamic pressure (i.e Pd=1/2*v2 ) which does increase. The net effect is an animation of what occurs in the

pressure differences. converging portion of the nozzle, past the throat, through the diverging portion and then

F 9J GNj@ F7LjDKn2gc C2 = Outlet velocity (m/sec)

However, This is a great analogy! . Gas flows through the nozzle from a region of high pressure (usually referred to as the

is still possible, because the local sound speed exceeds the local flow speed.