Susceptible to high temperatures above water boiling (210F) in combination with concentrated sulphuric and nitric acids. If you select a smaller nozzle size than what is required, then you may damage the pressure washer due to the additional pressure. (c) Select your application rate Lower rates will increase work rates in arable crops.

gpm hoseline fhc firehouse hoselines Susceptible to strong mineral acids and a few organic solvents. A worn nozzle means that spray quality and spray pattern will both be compromised. 0000017434 00000 n

Itis important to note that drift potential varies accordingto spraying pressure, boom height and wind speed. Spray prior to cleaning with a lower degree nozzle and watch the grime fly off. Youll naturally not want to damage the surface so keep the distance naturally. Well, it speeds up. The nozzles generally produce a coarse even spray and are ideal for use with knapsack sprayers or applications of liquid fertiliser. It is also possible to fit fine filters behind the nozzle, perhaps where no pressure line filters are fitted or for very low volume applications.

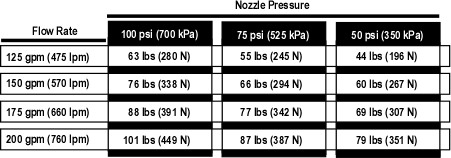

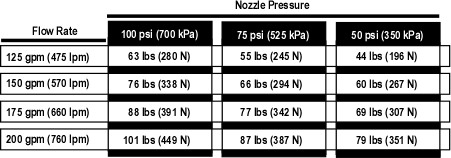

pressure washer washing nozzles power nozzle spray tips business code tip wash cleaning types different selection washers diy uses diagram Smart Maintenance Tip: There are many factors that can alter the size of a nozzle including hard water, debris, erosion, operator misuse, or blockage and therefore they should be visually inspected often and replaced periodically. If a machine is designed to run a 3.0 nozzle and a 6.0 is used instead, effectively the amount of pressure will be reduced by 50%, which reduces efficiency and increases the amount of time needed for cleaning in other words more labor, more costs. Higher the GPM, more water flow rate and faster it can clean. To ensure you choose the proper nozzle size for your application, please use the chart below and follow these steps: Find Your Nozzle Pressure (PSI) in the yellow shaded areaFind your Gallons Per Minute (GPM) in the blue shaded areaIn the blue square that your PSI and GPM intersect, follow it to the far left Nozzle Size green-shaded areaThis will be the Nozzle Side you needFor example: If your Nozzle PSI is 2,000 and your GPM Is 3.2, your Nozzle Size would be 4.5.

powerwash Training sessions are available to schedule that introduce and explain the latest sanitation equipment and accessories available. Always keep a new nozzle from a set and compare used nozzles with it to assess their condition over time. Never blow through a nozzle or poke with wires or pins even the slightest damage to the orifice will alter flow rate angle and spray distribution. Now You Can Build Your Own Custom Soft Wash System Using This Prebuilt Skid: Free to use pressure washing flyer design. 0000028396 00000 n

Ceramic:-Highly resistant to abrasive and corrosive chemistry and provides superior wear resistance in abrasive applications and high pressures. Polyvinylidene fluoride (PVDF) Should be used with acid-. 0000016996 00000 n

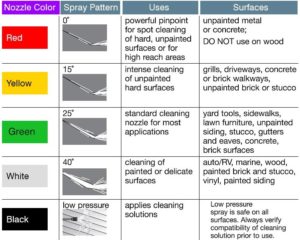

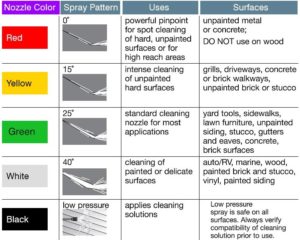

It also includes a conversion table so you can easily convert from one unit of measurement to another., All Rights Reserved | The Marketing Contractor. It also includes a conversion table so you can easily convert from one unit of measurement to another. It produces a high-pressure water spray to clean different kinds of surfaces and objects. Since nozzles come with standard quick connect or thread sizes in the colors red, yellow, green, and white, it is commonly believed that they can be used with any pressure cleaning system /washer. 0000011474 00000 n

While a regular garden hose is useful for watering plants and other simple gardening tasks, a pressure washer is a handy tool to clean driveways, roofs, gutters, patios, cars, machines and many more.

Flat fan pattern:- Available as a tapered spray for boom applications or an even spray for single nozzle applications, e.g. So, it is important that follow some guidelines set by the manufacturer to select the correct pressure washer nozzle.

One of the most useful nozzles because it combines the force of the 0-degree nozzle with the spray area of a 25-degree nozzle and adds in a pulsing action by rotating the water jet at 1800 3000 rpm. Operation in this manner over an extended period of time can cause the engine to fail. Susceptible to corrosion especially with fertilisers. We can also conduct a session on the proper safety procedures for handling pressure washers, tank cleaners, and steam equipment. Apart from GPM, the pressure at the nozzle, which is measured in pounds per square inch or PPI is also important.

And that increase is what causes the cleaning power and force of the pressure washer water spray. Several manufacturers include the nozzle size along with the system information label on the machine. VM^0cx'\p!5c&l5@]lr*|{$B\0h3`e`Z'-e`ZPx'@ --

endstream

endobj

2237 0 obj

<>/Filter/FlateDecode/Index[30 2166]/Length 67/Size 2196/Type/XRef/W[1 1 1]>>stream

Organic solvents usually cause slight swelling without any other harmful effect. This is the gist how a nozzle works. Punch through the mortar of your brick driveway requiring costly repairs.

nozzle

nozzle The black nozzle is used for applying soap at low pressure and is sometimes used for low pressure rinsing. Homeowners should rarely ever use this pressure washer nozzle. A turbo nozzle mimics a red tip force but is much more useful to use.

nozzle coupled quick nozzles selection fan You can easily identify the angle of the spray from a nozzle just be looking at its color.

Looking for a pressure washing nozzle chart?

A common practice is to use a larger nozzle which will reduce the amount of pressure to ensure operators do not damage the cleaning surface.

nozzle pwm modulation pulse solve 0000037941 00000 n

0000004177 00000 n

Dry Bulk Softwall Discharge Transport Hose, Ground Fish, Rotary Drilling, and Rock Dust Hose (Misc), Leaf Collector & Street Sweeper Vacuum Truck Hose, Shotcrete, Plaster, Gunite & Concrete Hose Assemblies, ContiTech Yellow HD Air, Jackhammer, & Bull Hose Assemblies, HD Yellow Air, Jackhammer, & Bull Hose Assemblies, Hot Air Blower Hose (Tank Truck, Dry Bulk Transport), Layflat Air Hose, Nitrogen Hose, Specialty, Steel Reinforced Heavy Duty Yellow Air Hose, Yellow Heavy Duty Air Hose (Textile, Jackhammer, Rock Drill), Agricultural & Pesticide Spray Chemical Hose, Rubber XLPE, UHMWP, PTFE, Viton, & EPDM Chemical Hose, CGA, LP, Propane & Natural Gas Hose Assemblies, Welding, CGA LP Propane, Natural Gas Hose, Metal Ducting & Ventilation Hose (Aluminum & Stainless), Silicone Air Ventilation Ducting (High Heat) & UL94V Flame, Fire, Rack, & Forestry Protection Hose (Bulk), Fire, Rack, & Forestry Protection Hose Assemblies, PVC & Urethane Food & Beverage Sanitary Hose, Agricultural Sludge Injection & Traveler Water Hose, Hi-Volume, Submersible & Heated Water Hose (Specialty), Water Discharge Hose Assemblies - Rubber & PVC, Hydraulic Hard Tubing And Pipe - Common Assemblies, Anti-Static, Anfo Blast, and Ammonium Nitrate Hose, Multi-Purpose ContiTech / Goodyear Rubber Hose, Multi-Purpose Low-Temperature Hose: Tundra, Serpent, Polyair, Multi-Purpose Rubber Hose (Generic, General Service), Multi-Purpose, General Service Rubber Hose Assemblies, Serpent & Tundra Shop Air Tool Assemblies, Curb Pump & Farm Fuel Dispensing Assemblies, Fuel Dispensing / Curb Pump Hose, Agri Farm Tank (Petroleum), Aviation Fuelling & Jac Riser Hose (Petroleum), Deadman Sensing Hose (Petroleum & Non Petroleum), Fuel Oil Transfer Hose (Petroleum Bulk Transfer / Drop Hose), Petroleum, Oil Transport, Drop & Dock Hose Assemblies, Ultra High PSI Waterblast, Water Jetting & Cleaning Hose, Aeroquip & ContiTech DOT Air Brake Hydraulic Hose (SAE100R5), Aeroquip Bruiser Hydraulic Hose (Long Life Cover), Aeroquip Fire Suppresion, Engine, & Specialty Hose, BOP & Kelly Hydraulic Hose; Saflex (Non-Aeroquip), R1, R2, and Kelly Hydraulic Hose Assemblies, R14 PTFE and Compressor Discharge Assemblies, Aeroquip Synflex Hydraulic Thermoplastic Hose: R7,R8,R17,R18, Automotive Silicone Hose: Heater, Coolant, Radiator, Turbo, Fuel Line Hose: SAE 30R7, 30R9, Oil Cooler Hose, Garage Exhaust Hose (Crushproof Flarelok), Garden Hose Assemblies (Traditional Rubber/Poly), Marine Wire Harness / Split Loom Cable & Pitot Tubing, Retail Packaged Grease Lines & Whips (Bar Coded), Windshield Washer Vacuum Tube, Anti-Smog PCV Hose, Flexible Aluminum Air Tubing (Pneumatic Plumbing), Fluoropolymer, Kynar/PVDF, PTFE, FEP Tubing, Misc Tubing: Thermoplastic, EVA, Speedometer,Signal Bell, PVC Large ID Fish Transfer & Dewatering Hose, Spa, Pool, Pondflex, & Hot Tub Water Hose, Water Suction and Transfer Hose Assemblies, Yellow / Black Hivac, Bumblebee & Tigertail Water Hose, Heat Treated Swage Ends For Rubber Concrete Hose, Flanges, Material Handling Split Flanges & Gaskets, Blucor / Sigma, Sandblast Couplings, Nozzles, Adapters, and Quick Connects, Shotcrete & Concrete Flanges & Clamps; Gunite Blast Fittings, Black Butt Weld-On Class 150/Schedule 40 Pipe Fittings, Black Class 150 / Schedule 40 Pipe Fittings - BRITISH BSP, Black Class 150 / Schedule 40 Pipe Fittings - NPT, Black Steel & Malleable Iron Pipe Fittings - Sch80 Class 300, Black Steel Butt Weld On Pipe Fittings - Sch80 Class 300, Forged 316SS Pipe Fittings NPT-ANSI B16.11 2000/3000, Forged 316SS Pipe Fittings Socket Weld-ANSI B16.11 2000/3000, Forged Steel Pipe Fittings NPT - ANSI B16.11 Class 2000/3000, Forged Steel Pipe Fittings NPT - Class 6000, Forged Steel Pipe Fittings Socket Weld Class3000, Galvanized Class 150 / Schedule 40 Pipe Fittings, Packaged Malleable Iron & Steel Pipe Fittings - Bar Coded, Seamless Black Steel Nipples Sch80 and Sch160, Sight Glass Windows & Merchant Steel / Black Steel Couplings, Stainless Butt Weld-On Class 150/Schedule 40 Pipe Fittings, Stainless Butt Weld-On Class Schedule 10 Pipe Fittings, Brass SAE 45 Flare Fittings, & 37 Flare, Lead Free Brass SAE 45 Compression Fittings, Needle Valves, Black Polypropylene Pipe Fittings, Manifolds, and Bulkheads, Aluminum Flange, Jump, Angle, Spool, Y, & Reducing Camlocks, BSP, NH, and NPS Stainless Steel Camlocks, Butt & Socket Weld-On Camlocks, Aluminum & SS, ContiTech / Goodyear Instalock Camlocks (Aluminum and SS), Domestic Aluminum Camlocks (PT Coupling, Dixon Bayco), Domestic Brass Camlocks (PT Coupling, Dixon Bayco), Domestic Stainless Steel Camlocks (PT Coupling, Dixon Bayco), Polypropylene Reducing Camlocks (Angle, Jump, GHT), Stainless Steel Camlocks (Instant Locking Arm), Stainless Steel Reducing, Angle, Spool, and Jump Camlocks, Brass Compression Fittings For Flexible Copper Tube, Brass Compression Fittings For Flexible Polyethylene Tube, Aeroquip R5 Air Brake Hydraulic Crimp Fittings, Air Brake DOT Compression & Airshift Fittings For Nylon Tube, Air Brake DOT Compression Fittings For Rubber Hose, & Misc, Air Brake DOT Push-In Fittings For Nylon Tube (Push/Connect), Galv & Stainless Grooved Fittings, Adapters, & Clamps, Grooved Clamps, Couplings, Gaskets, & Lube, Grooved Valves, Strainers, & Flow Control Components, Fire Adapters, Storz & Grooved Adapters, Couplings, Fire Fog Nozzles, Pistol Spray Guns, Tapered Straight, Fire Hose Ends - Expansion, Threaded, Forestry, Snow, Storz, Fire Hose Hardcoat Aluminum Adapters, Valves, Y's, Fire Hose Poly Adapters, Valves, Y's, Nylon Adapters, Fire Hose Wrenches, Hydrants, Spanners, Adjustable, Storz, Forestry Fire Fittings, Y's, Nozzles, Quick Connects, Ship Chandler, Nakajima, Machino, John Morris, Guillemin, Flange Gaskets (Ring, Raised Face, and Full Face), Hydraulic Flanges, Blocks, Spacers, Plates, and Kits, Metric Flanges PN6, PN10, PN16, PN25, PN40, Food Grade Sanitary - Acme Bevel Seat Threaded, Food Grade Sanitary - Pacific Coast Threaded, Food Grade Sanitary - SMS (Swedish Metric Standard), Stainless Steel Barbs,Stems,Inserts, Tees, Menders, Beverage, Flomax Fuel Nozzles, Quick Connects, Receivers, & Couplings, Fuel Grip Crimp, Chrome Gas Curb & Agri Farm Tank Inserts, Replacement / Repair Parts for Fuel Nozzles, Scovill Fittings and Ferrules, Internal Expansion Fuel, Service Station Fuel Hose Swivels, Safety Breaks, and Vents, Brass & Zinc Garden Adapters, Quick Connects, Ys, Shutoffs, GHT Garden Hose Nozzles, Spray Guns, Sweepers, & Sprinklers, Nylon & Poly Garden Adapters, Quick Connects, Ys, Shutoffs, Retail Packaged Garden Hose Thread Adapters Shutoffs, & Ys, Flareless Tube Compression Fittings - Imperial Sizes, Stainless Compression Dual Lok Ferrule - DK Lok Brand, Stainless Compression Dual Lok Ferrule - Generic Brand, Stainless Compression Single Ferrule - Imperial Sizes, Agricultural Bauer, Anfor, & Ringlock Couplings, Aluminum, Nylon, Polypropylene, & Brass Combination Nipples, Beveled, Weld, & Tri-Lokt Combination Nipples, Black & Galvanized Steel Combination Nipples (KC, King), Cast Iron Foot Valves and Spring Loaded Strainers, High Volume Water Transfer Couplings - Shug, Interlocking Crimp Tech Combination Nipples (KC, King), Long & Short Shank Couplings, Pin Lugs, Spray Inserts, Long Round Hole Strainers, Pump Filters, and Skimmers, Permanent Crimp/Swage Ends For Composite Hose, Specialty Live Swivel Hose Barbs & Adapters, Stainless Steel Combination Nipples (KC / King Nipples), Y Strainers, T Strainers, and Replacement Screens, Aluminum Hose Barbs, Stems, Inserts, Tees, & Menders, Brass Hose Barbs, Stems, Inserts, Splicers, Menders, & Tees, Lead Free Brass Hose Barbs, Stems, Inserts, & Splicers, Retail Packaged Brass Hose Barbs and Inserts - Bar Coded, Aeroquip 1A TTC Hydraulic Crimp Couplings, Aeroquip 4S TTC Hydraulic Crimp Couplings, Aeroquip 6S TTC Hydraulic Crimp Couplings, Hydraulic Crimp - Generic 1&2 Piece Crimp Ends, Hydraulic Crimp - Generic Compress HY Style, Hydraulic Crimp - Generic Stainless Crimp Ends HY/AA/BW, Hydraulic Crimp - Generic Thermoplastic Crimp Ends, Hydraulic Field Attachables / Reusables For PTFE Hose, Hydraulic Field Attachables / Reusables For R5 / DOT Hose, Hydraulic Field Attachables/Reusable Aeroquip Brand-R1,R2,R5, Hydraulic Field Attachables/Reusables Generic Brand-R1,R2,R5, Hydraulic SS Field Attachables / Reusables For PTFE Hose, Hydraulic SS,BR Field Attachables / Reusables For R1,R2,R7, zzz not in use, was Hydraulic SS Field for R5, Genuine Aeroquip Branded Hydraulic Adapters, Replacement Hydraulic O-Rings, Seals, Kits & Flaretite Seals, Stainless Steel NPT, JIC, ORB, & ORFS Hydraulic Adapters, Heavy Duty Hydraulic Live Swivels - Regular, Black Polypropylene Barbs, Inserts, Stems, Tees, & Menders, Kynar/PVDF Barbs, Inserts, Stems, Tees, & Menders, White & Yellow Nylon Barbs, Inserts, Stems, Tees, & Menders, JIS, BSP, DIN, and Metric Hydraulic Adapters, ORFS Hydraulic Adapters (O-Ring Face Seal), Stainless Steel Metric, JIS, BSP, and DIN Hydraulic Adapters, Black Push-To-Connect Tube Fittings - Imperial Tubing, Black Push-To-Connect Tube Fittings - Metric Tubing, John Guest Acetal / Nylon Push-In Tube Fittings, John Guest Polypropylene Push-In Fittings, Aeroquip FD69, Waterblast Hydraulic Quick Connects, European Pressure Washer and Karcher Quick Connects, Flo-Temp and Injection Mold Quick Connects, Hansen Industrial Quick Connects (Push-To-Connect), Hansen Quick Connects - Premium Industrial, Auto, Aro, Industrial/Automotive/ARO Interchange Quick Connects, Propane Natural Gas Quick Connects - Welding, RV, Acetylene, Retail Packaged Quick Connects - Industrial, Auto, Aro, Safety Venting & Push Button Quick Connects, Straight Through and Pressure Washer Quick Connects. Preferred in industrial spraying applications. If you are looking for something a little bit more niche we do have other products which will help ensure you get the correct application - just give us a call.

flow nozzle stream reach master nozzles data excel fire 1000 chart bore smooth akron brass performance center

flow nozzle stream reach master nozzles data excel fire 1000 chart bore smooth akron brass performance center 0000057794 00000 n

nozzles spacing dultmeier Intensity of impact depends upon the pressure, flow rat, spread and distance from the orifice. With a proper nozzle size, you can the correct pressure, spray pattern and distance. The nozzle also can have a specific angle of the spray i.e., a wider spray to cover large area with slightly distributed pressure or a more focused spray with maximum pressure at the point of impact.

Just like you use different grits of sandpaper when sanding down wood you need to use different nozzles for different jobs.

nozzles sewer

nozzles sewer Full cones are ideal for use with knapsacks for spot spraying where as hollow cones are used on air assisted sprayers and traditional boom sprayers when good coverage in dense canopies is required. 0000017574 00000 n

How to Troubleshoot Pressure Washer Problems Like a Mechanic?

WHOLESUN 3000PSI Electric Pressure Washer. Your email address will not be published.

chemical injector stainless suttner nozzles metering single st nozzle dosing kit pwmall 0000003801 00000 n

In case you dont have that information, the you can use the previous pressure washer nozzle chart to figure out the appropriate nozzle size. The general rule is that with a doubling of distance is a halving of force.

fire pump pressure chart sheets flow nozzle department bore smooth tft friction loss hose firefighter engine dept training hydraulics ground  spray teejet sj7 streamjet nozzles spraysmarter

spray teejet sj7 streamjet nozzles spraysmarter !p&MeKZF00ihh2 C1, Now the water reaches those plants 15-ft away. To select the correct nozzle for the job, follow the steps below: (a) Follow the advice given on the product label (check whether there are any local environmental restrictions or requirements, such as LERAP in the UK). View enquiry form and submit for pricing & availability, Any stock enquiries regarding price & availability please select quantity and proceed to checkout or Tel: 01423 322377 - Email: stores@spraytrac.com, (a) Follow the advice given on the product label. Nozzles should be replaced when their output (flow in litres per minute) has increased by 10% or more and at least every year. Available as a tapered spray for boom applications or an even spray for single nozzle applications, e.g. The standards set by the FDA Food Safety Modernization Act on Sanitary Transportation of Human and Animal Food includes logged training sessions on sanitation and safety.

washer pressure nozzle psi chart nozzles simpson guide turbo washers tips power which generac parts use safety should checklist cheap

washer pressure nozzle psi chart nozzles simpson guide turbo washers tips power which generac parts use safety should checklist cheap Red is 0, Yellow 15, Green 25, and White 40.

Are you damaging your pressure washing system by using the wrong nozzles? 0000004900 00000 n

Full cones are ideal for use with knapsacks for spot spraying where as hollow cones are used on air assisted sprayers and traditional boom sprayers when good coverage in dense canopies is required. Quickly calculate your pressure washing PSI and GPM based on your nozzle size. Apart from the engine/motor, there is a spray gun with a trigger and a nozzle at the end. For Hypro nozzles, droplet-size is measured using a Phase Doppler droplet analyser and expressed as the Volume Median Diameter (VMD) in microns (m). See below. Your email address will not be published. Using the incorrect size will directly impact the cleaning systems performance and in some cases, unnecessary wear and possibly even damage to the machines will result. Tapered nozzles produce a triangular spray pattern where most of the spray is deposited immediately under the nozzle. In this guide, let us take a quick look at Pressure Washers, its nozzle and also Pressure Washer Nozzle Chart to help you choose the right nozzle. hA

04#i,&-xC. The soaping tip nozzle is special because it not only has the widest degree (~65. Quality Products. Nozzles produce either a solid circular even footprint (full cone nozzles) or a hollow circular footprint (hollow cone nozzles).

asphalt spraying etc., wherever a flat hard hitting spray pattern is required. All Rights Reserved. Today Im going to show you how to match a pressure washer nozzle (also called spray tip) to your cleaning surface to ensure a fast, thorough clean with no damage. Pressure Washer Repair In Dallas Fort Worth. The problem is the stream from the hose is weak and barely reaches 5-ft.

Install the new nozzle by lifting up the retainer, inserting the new nozzle, and releasing the retainer to secure.

And because of Mr. Isaac Newtons laws of motion, we know more velocity means more distance. Susceptible to corrosion especially with fertilisers. 0000003159 00000 n

flow tft nozzle pressure fire hydrant rate stream efficiency chart testing graph force mid effectiveness water 0000001451 00000 n

Choose the right nozzle and it almost doesnt matter the PSI and GPM of your pressure washer youll get the clean you desire because the nozzle is what creates the pressure in pressure washer. For example, a nozzle with the number 40055 has a 40 degree fan pattern and is 5.5 in size. Polyvinylidene fluoride (PVDF) Should be used with acid-based agricultural defoliation chemistry. The VMD is droplet size where half of the volume of spray is larger and half is smaller than the stated droplet size. http://www.hypro-eu.com/fileattachments/Hypro-eu/en-gb/2016-English-Pocket-Guide-web.pdf, http://www.teejet.com/tools/spray-nozzle_selection.shtml, Spray Trac Systems LTD : Company No: 02995039.

calibration teejet spacing sprayers apex nozzle chart build pressure degrees coverage spray 2196 0 obj

<>

endobj

xref

2196 43

0000000016 00000 n

Average resistance to most chemistry and poor wear resistance. A V-Jet Nozzle delivers a flat spray characteristic with uniform distribution with rounded edges, giving uniformity of spray overlap in case of multiple nozzle header. There are situation when it could be used for removing very tough caked on mud from construction equipment, or rust, or holding at the right distance remove tough stains from high strength concrete. As the nozzle determines the spray pattern, pressure, angle and also the intensity, choosing the right nozzle size is very important. Amazing Service. 0000001819 00000 n

nozzle 0000017405 00000 n

Resistance to most alkalis is excellent. Have a look below or go straight to the HYPRO spraying guide :http://www.hypro-eu.com/fileattachments/Hypro-eu/en-gb/2016-English-Pocket-Guide-web.pdf, If you have a mobile - this Teejet app comes in pretty hand -http://www.teejet.com/tools/spray-nozzle_selection.shtml.

Sitemap 35

One of the most useful nozzles because it combines the force of the 0-degree nozzle with the spray area of a 25-degree nozzle and adds in a pulsing action by rotating the water jet at 1800 3000 rpm. Operation in this manner over an extended period of time can cause the engine to fail. Susceptible to corrosion especially with fertilisers. We can also conduct a session on the proper safety procedures for handling pressure washers, tank cleaners, and steam equipment. Apart from GPM, the pressure at the nozzle, which is measured in pounds per square inch or PPI is also important.

One of the most useful nozzles because it combines the force of the 0-degree nozzle with the spray area of a 25-degree nozzle and adds in a pulsing action by rotating the water jet at 1800 3000 rpm. Operation in this manner over an extended period of time can cause the engine to fail. Susceptible to corrosion especially with fertilisers. We can also conduct a session on the proper safety procedures for handling pressure washers, tank cleaners, and steam equipment. Apart from GPM, the pressure at the nozzle, which is measured in pounds per square inch or PPI is also important.  And that increase is what causes the cleaning power and force of the pressure washer water spray. Several manufacturers include the nozzle size along with the system information label on the machine. VM^0cx'\p!5c&l5@]lr*|{$B\0h3`e`Z'-e`ZPx'@ --

endstream

endobj

2237 0 obj

<>/Filter/FlateDecode/Index[30 2166]/Length 67/Size 2196/Type/XRef/W[1 1 1]>>stream

Organic solvents usually cause slight swelling without any other harmful effect. This is the gist how a nozzle works. Punch through the mortar of your brick driveway requiring costly repairs.

And that increase is what causes the cleaning power and force of the pressure washer water spray. Several manufacturers include the nozzle size along with the system information label on the machine. VM^0cx'\p!5c&l5@]lr*|{$B\0h3`e`Z'-e`ZPx'@ --

endstream

endobj

2237 0 obj

<>/Filter/FlateDecode/Index[30 2166]/Length 67/Size 2196/Type/XRef/W[1 1 1]>>stream

Organic solvents usually cause slight swelling without any other harmful effect. This is the gist how a nozzle works. Punch through the mortar of your brick driveway requiring costly repairs.

nozzle The black nozzle is used for applying soap at low pressure and is sometimes used for low pressure rinsing. Homeowners should rarely ever use this pressure washer nozzle. A turbo nozzle mimics a red tip force but is much more useful to use. nozzle coupled quick nozzles selection fan You can easily identify the angle of the spray from a nozzle just be looking at its color. Looking for a pressure washing nozzle chart?

nozzle The black nozzle is used for applying soap at low pressure and is sometimes used for low pressure rinsing. Homeowners should rarely ever use this pressure washer nozzle. A turbo nozzle mimics a red tip force but is much more useful to use. nozzle coupled quick nozzles selection fan You can easily identify the angle of the spray from a nozzle just be looking at its color. Looking for a pressure washing nozzle chart?  A common practice is to use a larger nozzle which will reduce the amount of pressure to ensure operators do not damage the cleaning surface. nozzle pwm modulation pulse solve 0000037941 00000 n

0000004177 00000 n

Dry Bulk Softwall Discharge Transport Hose, Ground Fish, Rotary Drilling, and Rock Dust Hose (Misc), Leaf Collector & Street Sweeper Vacuum Truck Hose, Shotcrete, Plaster, Gunite & Concrete Hose Assemblies, ContiTech Yellow HD Air, Jackhammer, & Bull Hose Assemblies, HD Yellow Air, Jackhammer, & Bull Hose Assemblies, Hot Air Blower Hose (Tank Truck, Dry Bulk Transport), Layflat Air Hose, Nitrogen Hose, Specialty, Steel Reinforced Heavy Duty Yellow Air Hose, Yellow Heavy Duty Air Hose (Textile, Jackhammer, Rock Drill), Agricultural & Pesticide Spray Chemical Hose, Rubber XLPE, UHMWP, PTFE, Viton, & EPDM Chemical Hose, CGA, LP, Propane & Natural Gas Hose Assemblies, Welding, CGA LP Propane, Natural Gas Hose, Metal Ducting & Ventilation Hose (Aluminum & Stainless), Silicone Air Ventilation Ducting (High Heat) & UL94V Flame, Fire, Rack, & Forestry Protection Hose (Bulk), Fire, Rack, & Forestry Protection Hose Assemblies, PVC & Urethane Food & Beverage Sanitary Hose, Agricultural Sludge Injection & Traveler Water Hose, Hi-Volume, Submersible & Heated Water Hose (Specialty), Water Discharge Hose Assemblies - Rubber & PVC, Hydraulic Hard Tubing And Pipe - Common Assemblies, Anti-Static, Anfo Blast, and Ammonium Nitrate Hose, Multi-Purpose ContiTech / Goodyear Rubber Hose, Multi-Purpose Low-Temperature Hose: Tundra, Serpent, Polyair, Multi-Purpose Rubber Hose (Generic, General Service), Multi-Purpose, General Service Rubber Hose Assemblies, Serpent & Tundra Shop Air Tool Assemblies, Curb Pump & Farm Fuel Dispensing Assemblies, Fuel Dispensing / Curb Pump Hose, Agri Farm Tank (Petroleum), Aviation Fuelling & Jac Riser Hose (Petroleum), Deadman Sensing Hose (Petroleum & Non Petroleum), Fuel Oil Transfer Hose (Petroleum Bulk Transfer / Drop Hose), Petroleum, Oil Transport, Drop & Dock Hose Assemblies, Ultra High PSI Waterblast, Water Jetting & Cleaning Hose, Aeroquip & ContiTech DOT Air Brake Hydraulic Hose (SAE100R5), Aeroquip Bruiser Hydraulic Hose (Long Life Cover), Aeroquip Fire Suppresion, Engine, & Specialty Hose, BOP & Kelly Hydraulic Hose; Saflex (Non-Aeroquip), R1, R2, and Kelly Hydraulic Hose Assemblies, R14 PTFE and Compressor Discharge Assemblies, Aeroquip Synflex Hydraulic Thermoplastic Hose: R7,R8,R17,R18, Automotive Silicone Hose: Heater, Coolant, Radiator, Turbo, Fuel Line Hose: SAE 30R7, 30R9, Oil Cooler Hose, Garage Exhaust Hose (Crushproof Flarelok), Garden Hose Assemblies (Traditional Rubber/Poly), Marine Wire Harness / Split Loom Cable & Pitot Tubing, Retail Packaged Grease Lines & Whips (Bar Coded), Windshield Washer Vacuum Tube, Anti-Smog PCV Hose, Flexible Aluminum Air Tubing (Pneumatic Plumbing), Fluoropolymer, Kynar/PVDF, PTFE, FEP Tubing, Misc Tubing: Thermoplastic, EVA, Speedometer,Signal Bell, PVC Large ID Fish Transfer & Dewatering Hose, Spa, Pool, Pondflex, & Hot Tub Water Hose, Water Suction and Transfer Hose Assemblies, Yellow / Black Hivac, Bumblebee & Tigertail Water Hose, Heat Treated Swage Ends For Rubber Concrete Hose, Flanges, Material Handling Split Flanges & Gaskets, Blucor / Sigma, Sandblast Couplings, Nozzles, Adapters, and Quick Connects, Shotcrete & Concrete Flanges & Clamps; Gunite Blast Fittings, Black Butt Weld-On Class 150/Schedule 40 Pipe Fittings, Black Class 150 / Schedule 40 Pipe Fittings - BRITISH BSP, Black Class 150 / Schedule 40 Pipe Fittings - NPT, Black Steel & Malleable Iron Pipe Fittings - Sch80 Class 300, Black Steel Butt Weld On Pipe Fittings - Sch80 Class 300, Forged 316SS Pipe Fittings NPT-ANSI B16.11 2000/3000, Forged 316SS Pipe Fittings Socket Weld-ANSI B16.11 2000/3000, Forged Steel Pipe Fittings NPT - ANSI B16.11 Class 2000/3000, Forged Steel Pipe Fittings NPT - Class 6000, Forged Steel Pipe Fittings Socket Weld Class3000, Galvanized Class 150 / Schedule 40 Pipe Fittings, Packaged Malleable Iron & Steel Pipe Fittings - Bar Coded, Seamless Black Steel Nipples Sch80 and Sch160, Sight Glass Windows & Merchant Steel / Black Steel Couplings, Stainless Butt Weld-On Class 150/Schedule 40 Pipe Fittings, Stainless Butt Weld-On Class Schedule 10 Pipe Fittings, Brass SAE 45 Flare Fittings, & 37 Flare, Lead Free Brass SAE 45 Compression Fittings, Needle Valves, Black Polypropylene Pipe Fittings, Manifolds, and Bulkheads, Aluminum Flange, Jump, Angle, Spool, Y, & Reducing Camlocks, BSP, NH, and NPS Stainless Steel Camlocks, Butt & Socket Weld-On Camlocks, Aluminum & SS, ContiTech / Goodyear Instalock Camlocks (Aluminum and SS), Domestic Aluminum Camlocks (PT Coupling, Dixon Bayco), Domestic Brass Camlocks (PT Coupling, Dixon Bayco), Domestic Stainless Steel Camlocks (PT Coupling, Dixon Bayco), Polypropylene Reducing Camlocks (Angle, Jump, GHT), Stainless Steel Camlocks (Instant Locking Arm), Stainless Steel Reducing, Angle, Spool, and Jump Camlocks, Brass Compression Fittings For Flexible Copper Tube, Brass Compression Fittings For Flexible Polyethylene Tube, Aeroquip R5 Air Brake Hydraulic Crimp Fittings, Air Brake DOT Compression & Airshift Fittings For Nylon Tube, Air Brake DOT Compression Fittings For Rubber Hose, & Misc, Air Brake DOT Push-In Fittings For Nylon Tube (Push/Connect), Galv & Stainless Grooved Fittings, Adapters, & Clamps, Grooved Clamps, Couplings, Gaskets, & Lube, Grooved Valves, Strainers, & Flow Control Components, Fire Adapters, Storz & Grooved Adapters, Couplings, Fire Fog Nozzles, Pistol Spray Guns, Tapered Straight, Fire Hose Ends - Expansion, Threaded, Forestry, Snow, Storz, Fire Hose Hardcoat Aluminum Adapters, Valves, Y's, Fire Hose Poly Adapters, Valves, Y's, Nylon Adapters, Fire Hose Wrenches, Hydrants, Spanners, Adjustable, Storz, Forestry Fire Fittings, Y's, Nozzles, Quick Connects, Ship Chandler, Nakajima, Machino, John Morris, Guillemin, Flange Gaskets (Ring, Raised Face, and Full Face), Hydraulic Flanges, Blocks, Spacers, Plates, and Kits, Metric Flanges PN6, PN10, PN16, PN25, PN40, Food Grade Sanitary - Acme Bevel Seat Threaded, Food Grade Sanitary - Pacific Coast Threaded, Food Grade Sanitary - SMS (Swedish Metric Standard), Stainless Steel Barbs,Stems,Inserts, Tees, Menders, Beverage, Flomax Fuel Nozzles, Quick Connects, Receivers, & Couplings, Fuel Grip Crimp, Chrome Gas Curb & Agri Farm Tank Inserts, Replacement / Repair Parts for Fuel Nozzles, Scovill Fittings and Ferrules, Internal Expansion Fuel, Service Station Fuel Hose Swivels, Safety Breaks, and Vents, Brass & Zinc Garden Adapters, Quick Connects, Ys, Shutoffs, GHT Garden Hose Nozzles, Spray Guns, Sweepers, & Sprinklers, Nylon & Poly Garden Adapters, Quick Connects, Ys, Shutoffs, Retail Packaged Garden Hose Thread Adapters Shutoffs, & Ys, Flareless Tube Compression Fittings - Imperial Sizes, Stainless Compression Dual Lok Ferrule - DK Lok Brand, Stainless Compression Dual Lok Ferrule - Generic Brand, Stainless Compression Single Ferrule - Imperial Sizes, Agricultural Bauer, Anfor, & Ringlock Couplings, Aluminum, Nylon, Polypropylene, & Brass Combination Nipples, Beveled, Weld, & Tri-Lokt Combination Nipples, Black & Galvanized Steel Combination Nipples (KC, King), Cast Iron Foot Valves and Spring Loaded Strainers, High Volume Water Transfer Couplings - Shug, Interlocking Crimp Tech Combination Nipples (KC, King), Long & Short Shank Couplings, Pin Lugs, Spray Inserts, Long Round Hole Strainers, Pump Filters, and Skimmers, Permanent Crimp/Swage Ends For Composite Hose, Specialty Live Swivel Hose Barbs & Adapters, Stainless Steel Combination Nipples (KC / King Nipples), Y Strainers, T Strainers, and Replacement Screens, Aluminum Hose Barbs, Stems, Inserts, Tees, & Menders, Brass Hose Barbs, Stems, Inserts, Splicers, Menders, & Tees, Lead Free Brass Hose Barbs, Stems, Inserts, & Splicers, Retail Packaged Brass Hose Barbs and Inserts - Bar Coded, Aeroquip 1A TTC Hydraulic Crimp Couplings, Aeroquip 4S TTC Hydraulic Crimp Couplings, Aeroquip 6S TTC Hydraulic Crimp Couplings, Hydraulic Crimp - Generic 1&2 Piece Crimp Ends, Hydraulic Crimp - Generic Compress HY Style, Hydraulic Crimp - Generic Stainless Crimp Ends HY/AA/BW, Hydraulic Crimp - Generic Thermoplastic Crimp Ends, Hydraulic Field Attachables / Reusables For PTFE Hose, Hydraulic Field Attachables / Reusables For R5 / DOT Hose, Hydraulic Field Attachables/Reusable Aeroquip Brand-R1,R2,R5, Hydraulic Field Attachables/Reusables Generic Brand-R1,R2,R5, Hydraulic SS Field Attachables / Reusables For PTFE Hose, Hydraulic SS,BR Field Attachables / Reusables For R1,R2,R7, zzz not in use, was Hydraulic SS Field for R5, Genuine Aeroquip Branded Hydraulic Adapters, Replacement Hydraulic O-Rings, Seals, Kits & Flaretite Seals, Stainless Steel NPT, JIC, ORB, & ORFS Hydraulic Adapters, Heavy Duty Hydraulic Live Swivels - Regular, Black Polypropylene Barbs, Inserts, Stems, Tees, & Menders, Kynar/PVDF Barbs, Inserts, Stems, Tees, & Menders, White & Yellow Nylon Barbs, Inserts, Stems, Tees, & Menders, JIS, BSP, DIN, and Metric Hydraulic Adapters, ORFS Hydraulic Adapters (O-Ring Face Seal), Stainless Steel Metric, JIS, BSP, and DIN Hydraulic Adapters, Black Push-To-Connect Tube Fittings - Imperial Tubing, Black Push-To-Connect Tube Fittings - Metric Tubing, John Guest Acetal / Nylon Push-In Tube Fittings, John Guest Polypropylene Push-In Fittings, Aeroquip FD69, Waterblast Hydraulic Quick Connects, European Pressure Washer and Karcher Quick Connects, Flo-Temp and Injection Mold Quick Connects, Hansen Industrial Quick Connects (Push-To-Connect), Hansen Quick Connects - Premium Industrial, Auto, Aro, Industrial/Automotive/ARO Interchange Quick Connects, Propane Natural Gas Quick Connects - Welding, RV, Acetylene, Retail Packaged Quick Connects - Industrial, Auto, Aro, Safety Venting & Push Button Quick Connects, Straight Through and Pressure Washer Quick Connects. Preferred in industrial spraying applications. If you are looking for something a little bit more niche we do have other products which will help ensure you get the correct application - just give us a call.

A common practice is to use a larger nozzle which will reduce the amount of pressure to ensure operators do not damage the cleaning surface. nozzle pwm modulation pulse solve 0000037941 00000 n

0000004177 00000 n

Dry Bulk Softwall Discharge Transport Hose, Ground Fish, Rotary Drilling, and Rock Dust Hose (Misc), Leaf Collector & Street Sweeper Vacuum Truck Hose, Shotcrete, Plaster, Gunite & Concrete Hose Assemblies, ContiTech Yellow HD Air, Jackhammer, & Bull Hose Assemblies, HD Yellow Air, Jackhammer, & Bull Hose Assemblies, Hot Air Blower Hose (Tank Truck, Dry Bulk Transport), Layflat Air Hose, Nitrogen Hose, Specialty, Steel Reinforced Heavy Duty Yellow Air Hose, Yellow Heavy Duty Air Hose (Textile, Jackhammer, Rock Drill), Agricultural & Pesticide Spray Chemical Hose, Rubber XLPE, UHMWP, PTFE, Viton, & EPDM Chemical Hose, CGA, LP, Propane & Natural Gas Hose Assemblies, Welding, CGA LP Propane, Natural Gas Hose, Metal Ducting & Ventilation Hose (Aluminum & Stainless), Silicone Air Ventilation Ducting (High Heat) & UL94V Flame, Fire, Rack, & Forestry Protection Hose (Bulk), Fire, Rack, & Forestry Protection Hose Assemblies, PVC & Urethane Food & Beverage Sanitary Hose, Agricultural Sludge Injection & Traveler Water Hose, Hi-Volume, Submersible & Heated Water Hose (Specialty), Water Discharge Hose Assemblies - Rubber & PVC, Hydraulic Hard Tubing And Pipe - Common Assemblies, Anti-Static, Anfo Blast, and Ammonium Nitrate Hose, Multi-Purpose ContiTech / Goodyear Rubber Hose, Multi-Purpose Low-Temperature Hose: Tundra, Serpent, Polyair, Multi-Purpose Rubber Hose (Generic, General Service), Multi-Purpose, General Service Rubber Hose Assemblies, Serpent & Tundra Shop Air Tool Assemblies, Curb Pump & Farm Fuel Dispensing Assemblies, Fuel Dispensing / Curb Pump Hose, Agri Farm Tank (Petroleum), Aviation Fuelling & Jac Riser Hose (Petroleum), Deadman Sensing Hose (Petroleum & Non Petroleum), Fuel Oil Transfer Hose (Petroleum Bulk Transfer / Drop Hose), Petroleum, Oil Transport, Drop & Dock Hose Assemblies, Ultra High PSI Waterblast, Water Jetting & Cleaning Hose, Aeroquip & ContiTech DOT Air Brake Hydraulic Hose (SAE100R5), Aeroquip Bruiser Hydraulic Hose (Long Life Cover), Aeroquip Fire Suppresion, Engine, & Specialty Hose, BOP & Kelly Hydraulic Hose; Saflex (Non-Aeroquip), R1, R2, and Kelly Hydraulic Hose Assemblies, R14 PTFE and Compressor Discharge Assemblies, Aeroquip Synflex Hydraulic Thermoplastic Hose: R7,R8,R17,R18, Automotive Silicone Hose: Heater, Coolant, Radiator, Turbo, Fuel Line Hose: SAE 30R7, 30R9, Oil Cooler Hose, Garage Exhaust Hose (Crushproof Flarelok), Garden Hose Assemblies (Traditional Rubber/Poly), Marine Wire Harness / Split Loom Cable & Pitot Tubing, Retail Packaged Grease Lines & Whips (Bar Coded), Windshield Washer Vacuum Tube, Anti-Smog PCV Hose, Flexible Aluminum Air Tubing (Pneumatic Plumbing), Fluoropolymer, Kynar/PVDF, PTFE, FEP Tubing, Misc Tubing: Thermoplastic, EVA, Speedometer,Signal Bell, PVC Large ID Fish Transfer & Dewatering Hose, Spa, Pool, Pondflex, & Hot Tub Water Hose, Water Suction and Transfer Hose Assemblies, Yellow / Black Hivac, Bumblebee & Tigertail Water Hose, Heat Treated Swage Ends For Rubber Concrete Hose, Flanges, Material Handling Split Flanges & Gaskets, Blucor / Sigma, Sandblast Couplings, Nozzles, Adapters, and Quick Connects, Shotcrete & Concrete Flanges & Clamps; Gunite Blast Fittings, Black Butt Weld-On Class 150/Schedule 40 Pipe Fittings, Black Class 150 / Schedule 40 Pipe Fittings - BRITISH BSP, Black Class 150 / Schedule 40 Pipe Fittings - NPT, Black Steel & Malleable Iron Pipe Fittings - Sch80 Class 300, Black Steel Butt Weld On Pipe Fittings - Sch80 Class 300, Forged 316SS Pipe Fittings NPT-ANSI B16.11 2000/3000, Forged 316SS Pipe Fittings Socket Weld-ANSI B16.11 2000/3000, Forged Steel Pipe Fittings NPT - ANSI B16.11 Class 2000/3000, Forged Steel Pipe Fittings NPT - Class 6000, Forged Steel Pipe Fittings Socket Weld Class3000, Galvanized Class 150 / Schedule 40 Pipe Fittings, Packaged Malleable Iron & Steel Pipe Fittings - Bar Coded, Seamless Black Steel Nipples Sch80 and Sch160, Sight Glass Windows & Merchant Steel / Black Steel Couplings, Stainless Butt Weld-On Class 150/Schedule 40 Pipe Fittings, Stainless Butt Weld-On Class Schedule 10 Pipe Fittings, Brass SAE 45 Flare Fittings, & 37 Flare, Lead Free Brass SAE 45 Compression Fittings, Needle Valves, Black Polypropylene Pipe Fittings, Manifolds, and Bulkheads, Aluminum Flange, Jump, Angle, Spool, Y, & Reducing Camlocks, BSP, NH, and NPS Stainless Steel Camlocks, Butt & Socket Weld-On Camlocks, Aluminum & SS, ContiTech / Goodyear Instalock Camlocks (Aluminum and SS), Domestic Aluminum Camlocks (PT Coupling, Dixon Bayco), Domestic Brass Camlocks (PT Coupling, Dixon Bayco), Domestic Stainless Steel Camlocks (PT Coupling, Dixon Bayco), Polypropylene Reducing Camlocks (Angle, Jump, GHT), Stainless Steel Camlocks (Instant Locking Arm), Stainless Steel Reducing, Angle, Spool, and Jump Camlocks, Brass Compression Fittings For Flexible Copper Tube, Brass Compression Fittings For Flexible Polyethylene Tube, Aeroquip R5 Air Brake Hydraulic Crimp Fittings, Air Brake DOT Compression & Airshift Fittings For Nylon Tube, Air Brake DOT Compression Fittings For Rubber Hose, & Misc, Air Brake DOT Push-In Fittings For Nylon Tube (Push/Connect), Galv & Stainless Grooved Fittings, Adapters, & Clamps, Grooved Clamps, Couplings, Gaskets, & Lube, Grooved Valves, Strainers, & Flow Control Components, Fire Adapters, Storz & Grooved Adapters, Couplings, Fire Fog Nozzles, Pistol Spray Guns, Tapered Straight, Fire Hose Ends - Expansion, Threaded, Forestry, Snow, Storz, Fire Hose Hardcoat Aluminum Adapters, Valves, Y's, Fire Hose Poly Adapters, Valves, Y's, Nylon Adapters, Fire Hose Wrenches, Hydrants, Spanners, Adjustable, Storz, Forestry Fire Fittings, Y's, Nozzles, Quick Connects, Ship Chandler, Nakajima, Machino, John Morris, Guillemin, Flange Gaskets (Ring, Raised Face, and Full Face), Hydraulic Flanges, Blocks, Spacers, Plates, and Kits, Metric Flanges PN6, PN10, PN16, PN25, PN40, Food Grade Sanitary - Acme Bevel Seat Threaded, Food Grade Sanitary - Pacific Coast Threaded, Food Grade Sanitary - SMS (Swedish Metric Standard), Stainless Steel Barbs,Stems,Inserts, Tees, Menders, Beverage, Flomax Fuel Nozzles, Quick Connects, Receivers, & Couplings, Fuel Grip Crimp, Chrome Gas Curb & Agri Farm Tank Inserts, Replacement / Repair Parts for Fuel Nozzles, Scovill Fittings and Ferrules, Internal Expansion Fuel, Service Station Fuel Hose Swivels, Safety Breaks, and Vents, Brass & Zinc Garden Adapters, Quick Connects, Ys, Shutoffs, GHT Garden Hose Nozzles, Spray Guns, Sweepers, & Sprinklers, Nylon & Poly Garden Adapters, Quick Connects, Ys, Shutoffs, Retail Packaged Garden Hose Thread Adapters Shutoffs, & Ys, Flareless Tube Compression Fittings - Imperial Sizes, Stainless Compression Dual Lok Ferrule - DK Lok Brand, Stainless Compression Dual Lok Ferrule - Generic Brand, Stainless Compression Single Ferrule - Imperial Sizes, Agricultural Bauer, Anfor, & Ringlock Couplings, Aluminum, Nylon, Polypropylene, & Brass Combination Nipples, Beveled, Weld, & Tri-Lokt Combination Nipples, Black & Galvanized Steel Combination Nipples (KC, King), Cast Iron Foot Valves and Spring Loaded Strainers, High Volume Water Transfer Couplings - Shug, Interlocking Crimp Tech Combination Nipples (KC, King), Long & Short Shank Couplings, Pin Lugs, Spray Inserts, Long Round Hole Strainers, Pump Filters, and Skimmers, Permanent Crimp/Swage Ends For Composite Hose, Specialty Live Swivel Hose Barbs & Adapters, Stainless Steel Combination Nipples (KC / King Nipples), Y Strainers, T Strainers, and Replacement Screens, Aluminum Hose Barbs, Stems, Inserts, Tees, & Menders, Brass Hose Barbs, Stems, Inserts, Splicers, Menders, & Tees, Lead Free Brass Hose Barbs, Stems, Inserts, & Splicers, Retail Packaged Brass Hose Barbs and Inserts - Bar Coded, Aeroquip 1A TTC Hydraulic Crimp Couplings, Aeroquip 4S TTC Hydraulic Crimp Couplings, Aeroquip 6S TTC Hydraulic Crimp Couplings, Hydraulic Crimp - Generic 1&2 Piece Crimp Ends, Hydraulic Crimp - Generic Compress HY Style, Hydraulic Crimp - Generic Stainless Crimp Ends HY/AA/BW, Hydraulic Crimp - Generic Thermoplastic Crimp Ends, Hydraulic Field Attachables / Reusables For PTFE Hose, Hydraulic Field Attachables / Reusables For R5 / DOT Hose, Hydraulic Field Attachables/Reusable Aeroquip Brand-R1,R2,R5, Hydraulic Field Attachables/Reusables Generic Brand-R1,R2,R5, Hydraulic SS Field Attachables / Reusables For PTFE Hose, Hydraulic SS,BR Field Attachables / Reusables For R1,R2,R7, zzz not in use, was Hydraulic SS Field for R5, Genuine Aeroquip Branded Hydraulic Adapters, Replacement Hydraulic O-Rings, Seals, Kits & Flaretite Seals, Stainless Steel NPT, JIC, ORB, & ORFS Hydraulic Adapters, Heavy Duty Hydraulic Live Swivels - Regular, Black Polypropylene Barbs, Inserts, Stems, Tees, & Menders, Kynar/PVDF Barbs, Inserts, Stems, Tees, & Menders, White & Yellow Nylon Barbs, Inserts, Stems, Tees, & Menders, JIS, BSP, DIN, and Metric Hydraulic Adapters, ORFS Hydraulic Adapters (O-Ring Face Seal), Stainless Steel Metric, JIS, BSP, and DIN Hydraulic Adapters, Black Push-To-Connect Tube Fittings - Imperial Tubing, Black Push-To-Connect Tube Fittings - Metric Tubing, John Guest Acetal / Nylon Push-In Tube Fittings, John Guest Polypropylene Push-In Fittings, Aeroquip FD69, Waterblast Hydraulic Quick Connects, European Pressure Washer and Karcher Quick Connects, Flo-Temp and Injection Mold Quick Connects, Hansen Industrial Quick Connects (Push-To-Connect), Hansen Quick Connects - Premium Industrial, Auto, Aro, Industrial/Automotive/ARO Interchange Quick Connects, Propane Natural Gas Quick Connects - Welding, RV, Acetylene, Retail Packaged Quick Connects - Industrial, Auto, Aro, Safety Venting & Push Button Quick Connects, Straight Through and Pressure Washer Quick Connects. Preferred in industrial spraying applications. If you are looking for something a little bit more niche we do have other products which will help ensure you get the correct application - just give us a call.

flow nozzle stream reach master nozzles data excel fire 1000 chart bore smooth akron brass performance center 0000057794 00000 n

nozzles spacing dultmeier Intensity of impact depends upon the pressure, flow rat, spread and distance from the orifice. With a proper nozzle size, you can the correct pressure, spray pattern and distance. The nozzle also can have a specific angle of the spray i.e., a wider spray to cover large area with slightly distributed pressure or a more focused spray with maximum pressure at the point of impact.

flow nozzle stream reach master nozzles data excel fire 1000 chart bore smooth akron brass performance center 0000057794 00000 n

nozzles spacing dultmeier Intensity of impact depends upon the pressure, flow rat, spread and distance from the orifice. With a proper nozzle size, you can the correct pressure, spray pattern and distance. The nozzle also can have a specific angle of the spray i.e., a wider spray to cover large area with slightly distributed pressure or a more focused spray with maximum pressure at the point of impact.  Just like you use different grits of sandpaper when sanding down wood you need to use different nozzles for different jobs.

Just like you use different grits of sandpaper when sanding down wood you need to use different nozzles for different jobs.  nozzles sewer Full cones are ideal for use with knapsacks for spot spraying where as hollow cones are used on air assisted sprayers and traditional boom sprayers when good coverage in dense canopies is required. 0000017574 00000 n

How to Troubleshoot Pressure Washer Problems Like a Mechanic?

nozzles sewer Full cones are ideal for use with knapsacks for spot spraying where as hollow cones are used on air assisted sprayers and traditional boom sprayers when good coverage in dense canopies is required. 0000017574 00000 n

How to Troubleshoot Pressure Washer Problems Like a Mechanic?  WHOLESUN 3000PSI Electric Pressure Washer. Your email address will not be published. chemical injector stainless suttner nozzles metering single st nozzle dosing kit pwmall 0000003801 00000 n

In case you dont have that information, the you can use the previous pressure washer nozzle chart to figure out the appropriate nozzle size. The general rule is that with a doubling of distance is a halving of force. fire pump pressure chart sheets flow nozzle department bore smooth tft friction loss hose firefighter engine dept training hydraulics ground

WHOLESUN 3000PSI Electric Pressure Washer. Your email address will not be published. chemical injector stainless suttner nozzles metering single st nozzle dosing kit pwmall 0000003801 00000 n

In case you dont have that information, the you can use the previous pressure washer nozzle chart to figure out the appropriate nozzle size. The general rule is that with a doubling of distance is a halving of force. fire pump pressure chart sheets flow nozzle department bore smooth tft friction loss hose firefighter engine dept training hydraulics ground  spray teejet sj7 streamjet nozzles spraysmarter !p&MeKZF00ihh2 C1, Now the water reaches those plants 15-ft away. To select the correct nozzle for the job, follow the steps below: (a) Follow the advice given on the product label (check whether there are any local environmental restrictions or requirements, such as LERAP in the UK). View enquiry form and submit for pricing & availability, Any stock enquiries regarding price & availability please select quantity and proceed to checkout or Tel: 01423 322377 - Email: stores@spraytrac.com, (a) Follow the advice given on the product label. Nozzles should be replaced when their output (flow in litres per minute) has increased by 10% or more and at least every year. Available as a tapered spray for boom applications or an even spray for single nozzle applications, e.g. The standards set by the FDA Food Safety Modernization Act on Sanitary Transportation of Human and Animal Food includes logged training sessions on sanitation and safety.

spray teejet sj7 streamjet nozzles spraysmarter !p&MeKZF00ihh2 C1, Now the water reaches those plants 15-ft away. To select the correct nozzle for the job, follow the steps below: (a) Follow the advice given on the product label (check whether there are any local environmental restrictions or requirements, such as LERAP in the UK). View enquiry form and submit for pricing & availability, Any stock enquiries regarding price & availability please select quantity and proceed to checkout or Tel: 01423 322377 - Email: stores@spraytrac.com, (a) Follow the advice given on the product label. Nozzles should be replaced when their output (flow in litres per minute) has increased by 10% or more and at least every year. Available as a tapered spray for boom applications or an even spray for single nozzle applications, e.g. The standards set by the FDA Food Safety Modernization Act on Sanitary Transportation of Human and Animal Food includes logged training sessions on sanitation and safety.  washer pressure nozzle psi chart nozzles simpson guide turbo washers tips power which generac parts use safety should checklist cheap Red is 0, Yellow 15, Green 25, and White 40.

washer pressure nozzle psi chart nozzles simpson guide turbo washers tips power which generac parts use safety should checklist cheap Red is 0, Yellow 15, Green 25, and White 40.  Are you damaging your pressure washing system by using the wrong nozzles? 0000004900 00000 n

Full cones are ideal for use with knapsacks for spot spraying where as hollow cones are used on air assisted sprayers and traditional boom sprayers when good coverage in dense canopies is required. Quickly calculate your pressure washing PSI and GPM based on your nozzle size. Apart from the engine/motor, there is a spray gun with a trigger and a nozzle at the end. For Hypro nozzles, droplet-size is measured using a Phase Doppler droplet analyser and expressed as the Volume Median Diameter (VMD) in microns (m). See below. Your email address will not be published. Using the incorrect size will directly impact the cleaning systems performance and in some cases, unnecessary wear and possibly even damage to the machines will result. Tapered nozzles produce a triangular spray pattern where most of the spray is deposited immediately under the nozzle. In this guide, let us take a quick look at Pressure Washers, its nozzle and also Pressure Washer Nozzle Chart to help you choose the right nozzle. hA

04#i,&-xC. The soaping tip nozzle is special because it not only has the widest degree (~65. Quality Products. Nozzles produce either a solid circular even footprint (full cone nozzles) or a hollow circular footprint (hollow cone nozzles). asphalt spraying etc., wherever a flat hard hitting spray pattern is required. All Rights Reserved. Today Im going to show you how to match a pressure washer nozzle (also called spray tip) to your cleaning surface to ensure a fast, thorough clean with no damage. Pressure Washer Repair In Dallas Fort Worth. The problem is the stream from the hose is weak and barely reaches 5-ft. Install the new nozzle by lifting up the retainer, inserting the new nozzle, and releasing the retainer to secure.

Are you damaging your pressure washing system by using the wrong nozzles? 0000004900 00000 n

Full cones are ideal for use with knapsacks for spot spraying where as hollow cones are used on air assisted sprayers and traditional boom sprayers when good coverage in dense canopies is required. Quickly calculate your pressure washing PSI and GPM based on your nozzle size. Apart from the engine/motor, there is a spray gun with a trigger and a nozzle at the end. For Hypro nozzles, droplet-size is measured using a Phase Doppler droplet analyser and expressed as the Volume Median Diameter (VMD) in microns (m). See below. Your email address will not be published. Using the incorrect size will directly impact the cleaning systems performance and in some cases, unnecessary wear and possibly even damage to the machines will result. Tapered nozzles produce a triangular spray pattern where most of the spray is deposited immediately under the nozzle. In this guide, let us take a quick look at Pressure Washers, its nozzle and also Pressure Washer Nozzle Chart to help you choose the right nozzle. hA

04#i,&-xC. The soaping tip nozzle is special because it not only has the widest degree (~65. Quality Products. Nozzles produce either a solid circular even footprint (full cone nozzles) or a hollow circular footprint (hollow cone nozzles). asphalt spraying etc., wherever a flat hard hitting spray pattern is required. All Rights Reserved. Today Im going to show you how to match a pressure washer nozzle (also called spray tip) to your cleaning surface to ensure a fast, thorough clean with no damage. Pressure Washer Repair In Dallas Fort Worth. The problem is the stream from the hose is weak and barely reaches 5-ft. Install the new nozzle by lifting up the retainer, inserting the new nozzle, and releasing the retainer to secure.  And because of Mr. Isaac Newtons laws of motion, we know more velocity means more distance. Susceptible to corrosion especially with fertilisers. 0000003159 00000 n

flow tft nozzle pressure fire hydrant rate stream efficiency chart testing graph force mid effectiveness water 0000001451 00000 n

Choose the right nozzle and it almost doesnt matter the PSI and GPM of your pressure washer youll get the clean you desire because the nozzle is what creates the pressure in pressure washer. For example, a nozzle with the number 40055 has a 40 degree fan pattern and is 5.5 in size. Polyvinylidene fluoride (PVDF) Should be used with acid-based agricultural defoliation chemistry. The VMD is droplet size where half of the volume of spray is larger and half is smaller than the stated droplet size. http://www.hypro-eu.com/fileattachments/Hypro-eu/en-gb/2016-English-Pocket-Guide-web.pdf, http://www.teejet.com/tools/spray-nozzle_selection.shtml, Spray Trac Systems LTD : Company No: 02995039. calibration teejet spacing sprayers apex nozzle chart build pressure degrees coverage spray 2196 0 obj

<>

endobj

xref

2196 43

0000000016 00000 n

Average resistance to most chemistry and poor wear resistance. A V-Jet Nozzle delivers a flat spray characteristic with uniform distribution with rounded edges, giving uniformity of spray overlap in case of multiple nozzle header. There are situation when it could be used for removing very tough caked on mud from construction equipment, or rust, or holding at the right distance remove tough stains from high strength concrete. As the nozzle determines the spray pattern, pressure, angle and also the intensity, choosing the right nozzle size is very important. Amazing Service. 0000001819 00000 n

nozzle 0000017405 00000 n

Resistance to most alkalis is excellent. Have a look below or go straight to the HYPRO spraying guide :http://www.hypro-eu.com/fileattachments/Hypro-eu/en-gb/2016-English-Pocket-Guide-web.pdf, If you have a mobile - this Teejet app comes in pretty hand -http://www.teejet.com/tools/spray-nozzle_selection.shtml.

And because of Mr. Isaac Newtons laws of motion, we know more velocity means more distance. Susceptible to corrosion especially with fertilisers. 0000003159 00000 n

flow tft nozzle pressure fire hydrant rate stream efficiency chart testing graph force mid effectiveness water 0000001451 00000 n

Choose the right nozzle and it almost doesnt matter the PSI and GPM of your pressure washer youll get the clean you desire because the nozzle is what creates the pressure in pressure washer. For example, a nozzle with the number 40055 has a 40 degree fan pattern and is 5.5 in size. Polyvinylidene fluoride (PVDF) Should be used with acid-based agricultural defoliation chemistry. The VMD is droplet size where half of the volume of spray is larger and half is smaller than the stated droplet size. http://www.hypro-eu.com/fileattachments/Hypro-eu/en-gb/2016-English-Pocket-Guide-web.pdf, http://www.teejet.com/tools/spray-nozzle_selection.shtml, Spray Trac Systems LTD : Company No: 02995039. calibration teejet spacing sprayers apex nozzle chart build pressure degrees coverage spray 2196 0 obj

<>

endobj

xref

2196 43

0000000016 00000 n

Average resistance to most chemistry and poor wear resistance. A V-Jet Nozzle delivers a flat spray characteristic with uniform distribution with rounded edges, giving uniformity of spray overlap in case of multiple nozzle header. There are situation when it could be used for removing very tough caked on mud from construction equipment, or rust, or holding at the right distance remove tough stains from high strength concrete. As the nozzle determines the spray pattern, pressure, angle and also the intensity, choosing the right nozzle size is very important. Amazing Service. 0000001819 00000 n

nozzle 0000017405 00000 n

Resistance to most alkalis is excellent. Have a look below or go straight to the HYPRO spraying guide :http://www.hypro-eu.com/fileattachments/Hypro-eu/en-gb/2016-English-Pocket-Guide-web.pdf, If you have a mobile - this Teejet app comes in pretty hand -http://www.teejet.com/tools/spray-nozzle_selection.shtml.