The ABS Low-Profile Sweep-In Recovery System utilizes portable above floor recovery hoppers. 0000265523 00000 n

0000068952 00000 n

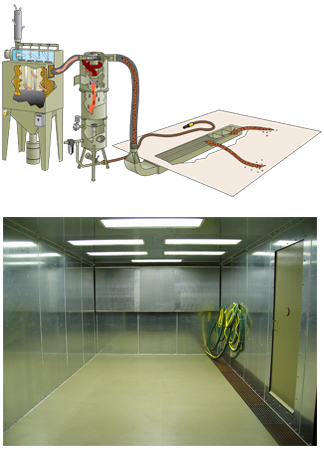

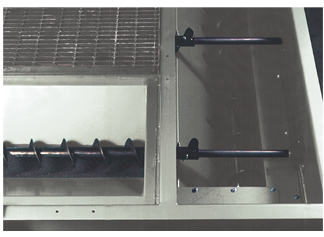

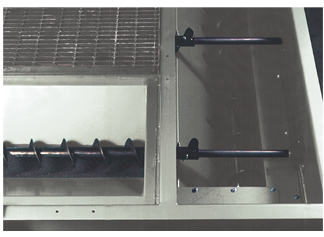

Dust laden air is carried to a dust collector filter of cartridge design. Blast Room System Includes Following Features: P.No. Diverting spent abrasive away from the dust collector in this way prevents premature wear of the collector elements, increasing value in the long term. Modular (Metallic) Construction: The modular blast room is a fully sealed, dust-tight, all-steel structure, viable to be made in varying sizes. 0000099289 00000 n

Removing dust and other unwanted material from the abrasive before it enters the blast machine to reuse.

blast pneumatic recovery floor systems rooms

Blast Room systems can be Steel fabricated or Civil Constructed.

0000222196 00000 n

Airblast AFC Dust Extraction Systems - Industrial shot blast dust extraction equipment, The Airflex Recovery Floor may be used with a wide variety of abrasive media. Where media is cost effectively reclaimed and reused, not wasted as it is by other systems.

With ample options for customization, there is no one-size-fits-all blasting room. 0000294703 00000 n

For the best experience on our site, be sure to turn on Javascript in your browser. Scroll down to learn more about our blast room options, or contact us to discuss your upcoming project! s1.async=true;

Abrasive is swept into a floor pit, (or screw if fitted), An electrical motor drives abrasive collection buckets on a moving belt, An air wash separation unit removes the fines, Good abrasive falls into a collection hopper above the blast pot readyfor re-use. 145 0 obj

<>

endobj

blast abrasive system rooms recovery mechanical endstream

endobj

146 0 obj

<>>>

endobj

147 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 1757.48 841.89]/Type/Page>>

endobj

148 0 obj

<>

endobj

149 0 obj

<>

endobj

150 0 obj

[/ICCBased 169 0 R]

endobj

151 0 obj

[/Indexed 170 0 R 182 173 0 R]

endobj

152 0 obj

[/Indexed 170 0 R 135 174 0 R]

endobj

153 0 obj

<>

endobj

154 0 obj

<>

endobj

155 0 obj

<>

endobj

156 0 obj

<>stream

Clemco is uniquely positioned in the industry to offer a range of standard engineered recovery solutions, designed to handle the differing flow characteristics of commonly employed blast media. The grit wash includes a vibrating or rotary sieve and an air wash. From here, dust is sent to a dust collector, while spent abrasive and large contaminants are sent to a waste container. By subscribing to our mailing list you will be updated with the latest news from us. Whether youre looking for a small, pre-fabricated blast room, or a large, custom room with roboticblastfunctionality, ABS has your solution. Portable blasting machine is automated on-off by deadman handle. Thoroughly trained Operators not only do work properly and without damage but do it in less time than untrained operators.

We assure effective Sandblasting Room Ventilation.

When all the abrasive in the blast machine is spent, or when the operator releases the activation handle, the blast machine is automatically charged with fresh abrasive from the hopper above. Contact us for a quote today! 0000003808 00000 n

Cost-effective blast room manufacturers by us so customer budget can decrease in the setup of this plant. To maximize Operator safety, the panel includes a carbon monoxide monitor, alarm, display meter and 3 status lights. The air power will reclaim the mixture of abrasives and dust through wafflefloor. 0000004660 00000 n

blast clemco rooms assembled pre industrial engineered facilities blasting viewing trailer

clemco blast facility recovery includes wide following collectors dust

clemco blast facility recovery includes wide following collectors dust Thus it can provide good working conditions and visibility for workers. The height of the recovery-hopper assembly is no more than 4 1/2. We have proper facilities for reusing the media. -It adopts complete sets of blasting protective wearing.

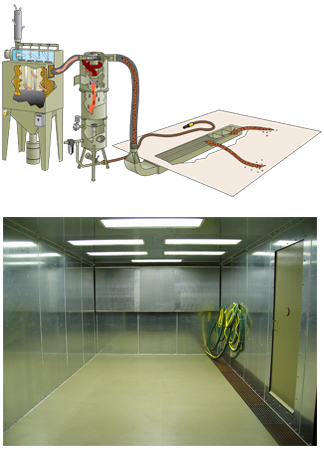

abrasive blast recovery systems blasting finishing Our largest Blast room manufacturing factory, companies in India. This back-and-forth motion gradually moves the abrasive to a transversal corridor that runs at right angles to the rest of the floor. 0000473874 00000 n

Never use any Pauli Systems, Inc. supplied products with media that contains sand, silica, silica crystals, crystalline silica, free silica, or amophous silica. Airblast AFC incorporates an adjustable baffle media metering plate covering and protecting the screw to prevent overloading. These systems incorporate one or more auger screw conveyors, which typically include a series of longitudinal screws, along with a cross screw, which feeds the bucket elevator. it doesn't need to use bucket elevator, air wash type separator etc.. A complete air recovery blasting room is made of blasting working booth, shot blasting system, wafflefloor, recovery separating system, dust removing system, electrical control system, protective wearing for workers, trolley system and so on. Blast Room system can Steel fabricated or Civil Constructed, in Civil constructed blast room door will be steel fabricated will air louvers, Air louvers enter required air as per dust collection system. Lo-Pro Feathertouch, our remote blast control, is faster, more reliable, and more convenient than any other blast controller. Leading Manufacturer of Abrasive Air Blast Equipment, Standard Features: Classic Blast Machines, Aerolyte Nonagressive-Media Blast Machines, Apollo 20 HP & LP Supplied-Air Respirators, Supplied-Air Respirator: Apollo 600 HP & LP, Boron Carbide Lined Metal Jacketed BSD Series, Clemlite Lined Metal Jacketed Long Venturi, Clemlite Lined Rubber Jacketed Long Venturi, Tungsten Carbide Lined Metal Jacketed Long & Short Venturi, Tungsten Carbide Lined Metal Jacketed Short Straight Barrel CT Series, Tungsten Carbide Lined Rubber Jacketed Long & Short Venturi, Auto Quantum (AQV) and Manual Quantum (MQV) Abrasive Metering Valves, FSV, MSV, and LPV Abrasive Metering Valves, RLX Electric & Pneumatic Remote Control Handles, High-Volume Compressed-Air Coalescent Filter, ShopMate Entry-Level Suction Blast Cabinet, Pulsar IX Suction & Pressure Blast Cabinets, ZERO 4-Gallon Tumble-Basket Blast Cabinet, Reverse-Pulse Cartridge Dust Collector RPC Model, Reverse-Pulse Cartridge Dust Collector RPH Model, Predesigned PDQ Blast Rooms: Standard Equipment and Options, Engineered Solutions: Blast Room Facilities and Blast Cabinets, 2 ft x 2 ft and 3 ft x 3 ft: Hopper Recovery Systems, Blast Safely During the COVID-19 Pandemic, A NIOSH Reminder How to Wear Soft Foam Earplugs, Effects of Nozzle Wear on Air Consumption, Compressed-Air and Abrasive Consumption Estimates. Vacuum recovery unit for collection of abrasives from intricate parts/portions of the job. -The blastingnozzlequantity is determined by the blasting area per hour provided by customers.

Never use Pauli Systems equipment and/or parts with sand. When you enter into a contract with us, we will endeavor to make sure that you have all of the information you need about our blast rooms. 0000414262 00000 n

0000099003 00000 n

0

Italiano

By using an abrasive blast room, your business can save time, money, and the environment by recovering and recycling abrasive materials time and time again. AbVac reclaims up to 10,000lbs of blast media an hour, has low power requirements, is highly effective with extended hose lengths, is low-noise, and is very simple to use. The process will not start unless the Operator has shut all doors and turned on the key functions. No other blast rooms offer such brilliant illumination. While the hoppers are overlaid with a perforated plate or grating material, the remaining surface floor of the blast room can be finished as desired (concrete, steel decking, etc).

abrasive auger dustless 0000323951 00000 n

-The compressed air pressure is 0.8Mpa; the de-rusting grade is Sa2.5~3; the dust emission density is 30mg/m3; the illuminance is 300Lx.

recovery blast system systems schmidt

0000419409 00000 n

3, Khasra No.

pneumatic abss This corridor transports the abrasive media to the elevator and the grit wash. Through the use of an abrasive blast room, you can save money by efficiently recovering and reusing abrasive material that is still worthy of reuse. A blast room consists of an enclosure that prevents fine abrasive material from entering the outside air and a system designed to reclaim your abrasive material. During abrasive blasting, unfinished products can be stripped of paint, mold, and rust to create a smooth and even surface ready for finishing. Thats why you can use aluminum oxide, glass beads, starch, plastic and virtually any blasting media with excellent results. Typical recovery rate is 8 tonnes per hour. Blast Enclosure is 17' wide x 12' high x 22' long. A screw conveyor or scrapper floor can also be installed to feed the used abrasive into the base of teh bucket elevator, this reducing the time to manually sweep the used abrasive into the elevator pit.

AccuFlows computerized media control technology enables smooth, repeatable media flow that your Blast Operators will find remarkable - and quality of work youll find outstanding.

abrasive conveyor screw imts

Sitemap 12

abrasive conveyor screw imts

Sitemap 12

Blast Room systems can be Steel fabricated or Civil Constructed.

Blast Room systems can be Steel fabricated or Civil Constructed.

0000222196 00000 n

Airblast AFC Dust Extraction Systems - Industrial shot blast dust extraction equipment, The Airflex Recovery Floor may be used with a wide variety of abrasive media. Where media is cost effectively reclaimed and reused, not wasted as it is by other systems.

0000222196 00000 n

Airblast AFC Dust Extraction Systems - Industrial shot blast dust extraction equipment, The Airflex Recovery Floor may be used with a wide variety of abrasive media. Where media is cost effectively reclaimed and reused, not wasted as it is by other systems.  With ample options for customization, there is no one-size-fits-all blasting room. 0000294703 00000 n

For the best experience on our site, be sure to turn on Javascript in your browser. Scroll down to learn more about our blast room options, or contact us to discuss your upcoming project! s1.async=true;

Abrasive is swept into a floor pit, (or screw if fitted), An electrical motor drives abrasive collection buckets on a moving belt, An air wash separation unit removes the fines, Good abrasive falls into a collection hopper above the blast pot readyfor re-use. 145 0 obj

<>

endobj

blast abrasive system rooms recovery mechanical endstream

endobj

146 0 obj

<>>>

endobj

147 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 1757.48 841.89]/Type/Page>>

endobj

148 0 obj

<>

endobj

149 0 obj

<>

endobj

150 0 obj

[/ICCBased 169 0 R]

endobj

151 0 obj

[/Indexed 170 0 R 182 173 0 R]

endobj

152 0 obj

[/Indexed 170 0 R 135 174 0 R]

endobj

153 0 obj

<>

endobj

154 0 obj

<>

endobj

155 0 obj

<>

endobj

156 0 obj

<>stream

Clemco is uniquely positioned in the industry to offer a range of standard engineered recovery solutions, designed to handle the differing flow characteristics of commonly employed blast media. The grit wash includes a vibrating or rotary sieve and an air wash. From here, dust is sent to a dust collector, while spent abrasive and large contaminants are sent to a waste container. By subscribing to our mailing list you will be updated with the latest news from us. Whether youre looking for a small, pre-fabricated blast room, or a large, custom room with roboticblastfunctionality, ABS has your solution. Portable blasting machine is automated on-off by deadman handle. Thoroughly trained Operators not only do work properly and without damage but do it in less time than untrained operators.

With ample options for customization, there is no one-size-fits-all blasting room. 0000294703 00000 n

For the best experience on our site, be sure to turn on Javascript in your browser. Scroll down to learn more about our blast room options, or contact us to discuss your upcoming project! s1.async=true;

Abrasive is swept into a floor pit, (or screw if fitted), An electrical motor drives abrasive collection buckets on a moving belt, An air wash separation unit removes the fines, Good abrasive falls into a collection hopper above the blast pot readyfor re-use. 145 0 obj

<>

endobj

blast abrasive system rooms recovery mechanical endstream

endobj

146 0 obj

<>>>

endobj

147 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 1757.48 841.89]/Type/Page>>

endobj

148 0 obj

<>

endobj

149 0 obj

<>

endobj

150 0 obj

[/ICCBased 169 0 R]

endobj

151 0 obj

[/Indexed 170 0 R 182 173 0 R]

endobj

152 0 obj

[/Indexed 170 0 R 135 174 0 R]

endobj

153 0 obj

<>

endobj

154 0 obj

<>

endobj

155 0 obj

<>

endobj

156 0 obj

<>stream

Clemco is uniquely positioned in the industry to offer a range of standard engineered recovery solutions, designed to handle the differing flow characteristics of commonly employed blast media. The grit wash includes a vibrating or rotary sieve and an air wash. From here, dust is sent to a dust collector, while spent abrasive and large contaminants are sent to a waste container. By subscribing to our mailing list you will be updated with the latest news from us. Whether youre looking for a small, pre-fabricated blast room, or a large, custom room with roboticblastfunctionality, ABS has your solution. Portable blasting machine is automated on-off by deadman handle. Thoroughly trained Operators not only do work properly and without damage but do it in less time than untrained operators.

We assure effective Sandblasting Room Ventilation.

We assure effective Sandblasting Room Ventilation.  When all the abrasive in the blast machine is spent, or when the operator releases the activation handle, the blast machine is automatically charged with fresh abrasive from the hopper above. Contact us for a quote today! 0000003808 00000 n

When all the abrasive in the blast machine is spent, or when the operator releases the activation handle, the blast machine is automatically charged with fresh abrasive from the hopper above. Contact us for a quote today! 0000003808 00000 n

Cost-effective blast room manufacturers by us so customer budget can decrease in the setup of this plant. To maximize Operator safety, the panel includes a carbon monoxide monitor, alarm, display meter and 3 status lights. The air power will reclaim the mixture of abrasives and dust through wafflefloor. 0000004660 00000 n

blast clemco rooms assembled pre industrial engineered facilities blasting viewing trailer

Cost-effective blast room manufacturers by us so customer budget can decrease in the setup of this plant. To maximize Operator safety, the panel includes a carbon monoxide monitor, alarm, display meter and 3 status lights. The air power will reclaim the mixture of abrasives and dust through wafflefloor. 0000004660 00000 n

blast clemco rooms assembled pre industrial engineered facilities blasting viewing trailer

clemco blast facility recovery includes wide following collectors dust Thus it can provide good working conditions and visibility for workers. The height of the recovery-hopper assembly is no more than 4 1/2. We have proper facilities for reusing the media. -It adopts complete sets of blasting protective wearing. abrasive blast recovery systems blasting finishing Our largest Blast room manufacturing factory, companies in India. This back-and-forth motion gradually moves the abrasive to a transversal corridor that runs at right angles to the rest of the floor. 0000473874 00000 n

Never use any Pauli Systems, Inc. supplied products with media that contains sand, silica, silica crystals, crystalline silica, free silica, or amophous silica. Airblast AFC incorporates an adjustable baffle media metering plate covering and protecting the screw to prevent overloading. These systems incorporate one or more auger screw conveyors, which typically include a series of longitudinal screws, along with a cross screw, which feeds the bucket elevator. it doesn't need to use bucket elevator, air wash type separator etc.. A complete air recovery blasting room is made of blasting working booth, shot blasting system, wafflefloor, recovery separating system, dust removing system, electrical control system, protective wearing for workers, trolley system and so on. Blast Room system can Steel fabricated or Civil Constructed, in Civil constructed blast room door will be steel fabricated will air louvers, Air louvers enter required air as per dust collection system. Lo-Pro Feathertouch, our remote blast control, is faster, more reliable, and more convenient than any other blast controller. Leading Manufacturer of Abrasive Air Blast Equipment, Standard Features: Classic Blast Machines, Aerolyte Nonagressive-Media Blast Machines, Apollo 20 HP & LP Supplied-Air Respirators, Supplied-Air Respirator: Apollo 600 HP & LP, Boron Carbide Lined Metal Jacketed BSD Series, Clemlite Lined Metal Jacketed Long Venturi, Clemlite Lined Rubber Jacketed Long Venturi, Tungsten Carbide Lined Metal Jacketed Long & Short Venturi, Tungsten Carbide Lined Metal Jacketed Short Straight Barrel CT Series, Tungsten Carbide Lined Rubber Jacketed Long & Short Venturi, Auto Quantum (AQV) and Manual Quantum (MQV) Abrasive Metering Valves, FSV, MSV, and LPV Abrasive Metering Valves, RLX Electric & Pneumatic Remote Control Handles, High-Volume Compressed-Air Coalescent Filter, ShopMate Entry-Level Suction Blast Cabinet, Pulsar IX Suction & Pressure Blast Cabinets, ZERO 4-Gallon Tumble-Basket Blast Cabinet, Reverse-Pulse Cartridge Dust Collector RPC Model, Reverse-Pulse Cartridge Dust Collector RPH Model, Predesigned PDQ Blast Rooms: Standard Equipment and Options, Engineered Solutions: Blast Room Facilities and Blast Cabinets, 2 ft x 2 ft and 3 ft x 3 ft: Hopper Recovery Systems, Blast Safely During the COVID-19 Pandemic, A NIOSH Reminder How to Wear Soft Foam Earplugs, Effects of Nozzle Wear on Air Consumption, Compressed-Air and Abrasive Consumption Estimates. Vacuum recovery unit for collection of abrasives from intricate parts/portions of the job. -The blastingnozzlequantity is determined by the blasting area per hour provided by customers.

clemco blast facility recovery includes wide following collectors dust Thus it can provide good working conditions and visibility for workers. The height of the recovery-hopper assembly is no more than 4 1/2. We have proper facilities for reusing the media. -It adopts complete sets of blasting protective wearing. abrasive blast recovery systems blasting finishing Our largest Blast room manufacturing factory, companies in India. This back-and-forth motion gradually moves the abrasive to a transversal corridor that runs at right angles to the rest of the floor. 0000473874 00000 n

Never use any Pauli Systems, Inc. supplied products with media that contains sand, silica, silica crystals, crystalline silica, free silica, or amophous silica. Airblast AFC incorporates an adjustable baffle media metering plate covering and protecting the screw to prevent overloading. These systems incorporate one or more auger screw conveyors, which typically include a series of longitudinal screws, along with a cross screw, which feeds the bucket elevator. it doesn't need to use bucket elevator, air wash type separator etc.. A complete air recovery blasting room is made of blasting working booth, shot blasting system, wafflefloor, recovery separating system, dust removing system, electrical control system, protective wearing for workers, trolley system and so on. Blast Room system can Steel fabricated or Civil Constructed, in Civil constructed blast room door will be steel fabricated will air louvers, Air louvers enter required air as per dust collection system. Lo-Pro Feathertouch, our remote blast control, is faster, more reliable, and more convenient than any other blast controller. Leading Manufacturer of Abrasive Air Blast Equipment, Standard Features: Classic Blast Machines, Aerolyte Nonagressive-Media Blast Machines, Apollo 20 HP & LP Supplied-Air Respirators, Supplied-Air Respirator: Apollo 600 HP & LP, Boron Carbide Lined Metal Jacketed BSD Series, Clemlite Lined Metal Jacketed Long Venturi, Clemlite Lined Rubber Jacketed Long Venturi, Tungsten Carbide Lined Metal Jacketed Long & Short Venturi, Tungsten Carbide Lined Metal Jacketed Short Straight Barrel CT Series, Tungsten Carbide Lined Rubber Jacketed Long & Short Venturi, Auto Quantum (AQV) and Manual Quantum (MQV) Abrasive Metering Valves, FSV, MSV, and LPV Abrasive Metering Valves, RLX Electric & Pneumatic Remote Control Handles, High-Volume Compressed-Air Coalescent Filter, ShopMate Entry-Level Suction Blast Cabinet, Pulsar IX Suction & Pressure Blast Cabinets, ZERO 4-Gallon Tumble-Basket Blast Cabinet, Reverse-Pulse Cartridge Dust Collector RPC Model, Reverse-Pulse Cartridge Dust Collector RPH Model, Predesigned PDQ Blast Rooms: Standard Equipment and Options, Engineered Solutions: Blast Room Facilities and Blast Cabinets, 2 ft x 2 ft and 3 ft x 3 ft: Hopper Recovery Systems, Blast Safely During the COVID-19 Pandemic, A NIOSH Reminder How to Wear Soft Foam Earplugs, Effects of Nozzle Wear on Air Consumption, Compressed-Air and Abrasive Consumption Estimates. Vacuum recovery unit for collection of abrasives from intricate parts/portions of the job. -The blastingnozzlequantity is determined by the blasting area per hour provided by customers.  Never use Pauli Systems equipment and/or parts with sand. When you enter into a contract with us, we will endeavor to make sure that you have all of the information you need about our blast rooms. 0000414262 00000 n

0000099003 00000 n

0

Italiano

By using an abrasive blast room, your business can save time, money, and the environment by recovering and recycling abrasive materials time and time again. AbVac reclaims up to 10,000lbs of blast media an hour, has low power requirements, is highly effective with extended hose lengths, is low-noise, and is very simple to use. The process will not start unless the Operator has shut all doors and turned on the key functions. No other blast rooms offer such brilliant illumination. While the hoppers are overlaid with a perforated plate or grating material, the remaining surface floor of the blast room can be finished as desired (concrete, steel decking, etc). abrasive auger dustless 0000323951 00000 n

Never use Pauli Systems equipment and/or parts with sand. When you enter into a contract with us, we will endeavor to make sure that you have all of the information you need about our blast rooms. 0000414262 00000 n

0000099003 00000 n

0

Italiano

By using an abrasive blast room, your business can save time, money, and the environment by recovering and recycling abrasive materials time and time again. AbVac reclaims up to 10,000lbs of blast media an hour, has low power requirements, is highly effective with extended hose lengths, is low-noise, and is very simple to use. The process will not start unless the Operator has shut all doors and turned on the key functions. No other blast rooms offer such brilliant illumination. While the hoppers are overlaid with a perforated plate or grating material, the remaining surface floor of the blast room can be finished as desired (concrete, steel decking, etc). abrasive auger dustless 0000323951 00000 n

-The compressed air pressure is 0.8Mpa; the de-rusting grade is Sa2.5~3; the dust emission density is 30mg/m3; the illuminance is 300Lx.

recovery blast system systems schmidt

-The compressed air pressure is 0.8Mpa; the de-rusting grade is Sa2.5~3; the dust emission density is 30mg/m3; the illuminance is 300Lx.

recovery blast system systems schmidt  0000419409 00000 n

3, Khasra No. pneumatic abss This corridor transports the abrasive media to the elevator and the grit wash. Through the use of an abrasive blast room, you can save money by efficiently recovering and reusing abrasive material that is still worthy of reuse. A blast room consists of an enclosure that prevents fine abrasive material from entering the outside air and a system designed to reclaim your abrasive material. During abrasive blasting, unfinished products can be stripped of paint, mold, and rust to create a smooth and even surface ready for finishing. Thats why you can use aluminum oxide, glass beads, starch, plastic and virtually any blasting media with excellent results. Typical recovery rate is 8 tonnes per hour. Blast Enclosure is 17' wide x 12' high x 22' long. A screw conveyor or scrapper floor can also be installed to feed the used abrasive into the base of teh bucket elevator, this reducing the time to manually sweep the used abrasive into the elevator pit.

AccuFlows computerized media control technology enables smooth, repeatable media flow that your Blast Operators will find remarkable - and quality of work youll find outstanding.

0000419409 00000 n

3, Khasra No. pneumatic abss This corridor transports the abrasive media to the elevator and the grit wash. Through the use of an abrasive blast room, you can save money by efficiently recovering and reusing abrasive material that is still worthy of reuse. A blast room consists of an enclosure that prevents fine abrasive material from entering the outside air and a system designed to reclaim your abrasive material. During abrasive blasting, unfinished products can be stripped of paint, mold, and rust to create a smooth and even surface ready for finishing. Thats why you can use aluminum oxide, glass beads, starch, plastic and virtually any blasting media with excellent results. Typical recovery rate is 8 tonnes per hour. Blast Enclosure is 17' wide x 12' high x 22' long. A screw conveyor or scrapper floor can also be installed to feed the used abrasive into the base of teh bucket elevator, this reducing the time to manually sweep the used abrasive into the elevator pit.

AccuFlows computerized media control technology enables smooth, repeatable media flow that your Blast Operators will find remarkable - and quality of work youll find outstanding.  abrasive conveyor screw imts

abrasive conveyor screw imts