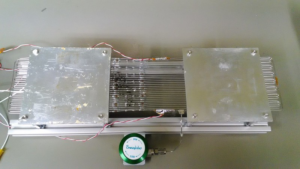

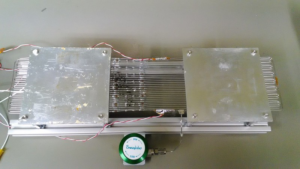

Energy Res. According to their model, sensible heat transfer accounts for 74% of the total heat. J. The research of Rahman M. L. et al. Sci. The design standard is determined by the Bond number: The study found (Zhang and Faghri, 2008) that only when Bo 2, that is, when the gravity is less than the surface tension, stable vapor slugs and liquid plugs will be formed in PHPs. The smaller the value, the smaller the power consumption and the higher the energy utilization rate. (2014) found that the performance of the PHP is the best when the mixing ratio of pure water and acetone is 13:1 under varying filling rates and heat input. Qu and Ma (2007) believe that when the inclination angle is 60, the best performance can be obtained. Experimental studies have shown that (Shafii et al., 2001; Vassilev et al., 2007), when the filling rate is 0.20.8, a series of liquid plugs and vapor slugs in the PHP can be formed to ensure normal pulsating operation. The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. Finally, the latest application and development of pulsating heat pipes applied to heat dissipation of high-power CPUs are summarized, which can provide a guidance for subsequent research and engineering application. Pulsating heat pipes can be used in racks and lower levels to eliminate local hot spots and uneven air distribution in the data centers, showing excellent heat dissipation performance. Adding a non-condensable gas (NCG), such as nitrogen or argon, to a standard heat pipe turns it into a variable conductance heat pipe. While its true that the most used vapor chambers closely mimic their heat pipe cousins (copper enclosure, sintered wick, water working fluid) they are designed to function as a planar heat spreading device and need a support structure to ensure adequate vapor flow and for structural integrity under clamping loads. Heat Mass Transfer 83, 586590. Continuous influx of new bubbles at the lower part of the liquid plug causes the pressure difference at both ends of the liquid plugs to increase, which pushes the high-temperature liquid plugs of the evaporator to move to the condenser. doi:10.1016/j.applthermaleng.2017.11.009, Lee, J., and Kim, S. J. J. Int. 28 (8), 33873394. Heat sink of (A) commercial VC-based and (B) our PHP-based radiator for 1U server heat dissipation. Heat Transfer 133 (8), 081504. doi:10.1115/1.4003759, Pachghare, P. R., and Mahalle, A. M. (2014). MAR.. doi:10.1016/j.ijheatmasstransfer.2018.11.002, Xie, F., Li, X., Qian, P., Huang, Z., and Liu, M. (2020). Among them, active cooling consists of forced air cooling, forced liquid cooling, refrigerating and thermoelectric cooling, etc., and passive cooling includes air or liquid natural convection, and phase change heat transfer (evaporation, condensation, boiling, and phase change materials).

oscillating thermocouples mississippi Thermal Performance of an Open Loop Closed End Pulsating Heat Pipe. In other words, the condenser must be above the evaporator. 4) Larger thermal conductivity can not only reduce the response time of PHPs, but also maintain the temperature uniformity of PHPs. 23/6, pp. Jnl Num Meth HFF 12 (5), 585609. When the temperature of the 16 CPUs in the rack does not exceed 60C, the maximum consumed power is 1380W, as shown in Figure 4C. Experimental Studies of Surface Modified Oscillating Heat Pipes. The hot end overheating leads to secondary heat dissipation difficulties, the cold end undercooling leads to CPU chip surface condensation affects its performance and life, and the manufacturing cost is too high, which also restricts the large-scale application of thermoelectric refrigeration technology. At this time, the mass-spring-damping model that provides power for fluid movement disappears. Sensible/latent heat are both heat transfer mechanisms of PHPs, but their respective proportions have not yet been fully understood. The heat pipe(s) and associated condenser (fin stack) must be designed to handle power and ambient temperature at the highest specification rating. The Relationship Among CPU Utilization, Temperature, and thermal Power for Waste Heat Utilization. Therm. Appl. 205 (Nov.1), 11651188. 6) Smaller fluid density can reduce the influence of gravity. All Rights Reserved.Privacy Policy | Cookie Policy. 18 (Tuesday) 9:00 am - 19 (Wednesday) 5:00 pm, About Us | Subscribe | Advertise | Contribute | Contact UsCopyright 2022 Lectrix. Therm. More turns will increase the heat exchange area, enhance the pulsation of the working fluids, and weaken the influence of gravity, which is helpful for startup. Summary of heat dissipation of high-power chips based on PHPs. doi:10.1016/j.ijheatmasstransfer.2016.11.036, Leu, T. S., and Wu, C. H. (2017). doi:10.1016/j.ijheatmasstransfer.2014.12.010, Xiahou, G., Zhang, J., Ma, R., and Liu, Y. Appl. The directional flow can promote more liquid to flow through the elbow of the evaporation section at a faster speed, reducing stagnation and improving the heat transfer performance of the PHPs (Thompson et al., 2011). A vertical PHP radiator for high heat flux CPU was proposed by Xiahou et al. IEEE 86 (1), 8285.

Moore, G. E. (2006). The effects of filling rate, input power and wind speed on the startup performance and heat transfer performance of the vertical radiator are experimentally studied, and compared with aluminum finned radiators. These include: Constant conductance heat pipes (standard or CCHP) and vapor chambers are by far the most prevalent type of heat pipe used for cooling electronics. The research on its heat transfer performance will be further elaborated in the subsequent articles. Boswell, J., Wilson, C., Pounds, D., and Drolen, B. doi:10.1016/j.ijheatmasstransfer.2012.06.024, Jo, J., Kim, J., and Kim, S. J. Heat Mass Transfer 55 (21-22), 61096120. Flat or 3D plate with bosses, through or blind holes, dielectric substrate, etc. Xing et al. Different pipe diameters, roughness, working fluids with different physical parameters and temperature operating ranges will all have an impact on the experimental conclusions. Int. PHP has unique advantages in solving heat dissipation because of its compact structure and high heat transfer coefficient, which has attracted much attention from scholars (Zuo et al., 1999). The improvement of computer hardware performance makes the heat flux increase sharply. Eng. Eng. Energies 11 (12), 3425. doi:10.3390/en11123425, Tseng, C.-Y., Yang, K.-S., Chien, K.-H., Jeng, M.-S., and Wang, C.-C. (2014). They are so named because of the intermittent pockets of liquid and vapor that pulsate back and forth as they move to cooler areas. Int.

heat cooling oscillating electronics military phase ohp pipes schematic drawing figure Temperature change of (A) the aluminum fin radiator, and (B) the novel vertical pulsating heat pipe radiator under different input power (Xiahou et al., 2019). Zhou, Y., Yang, H., Liu, L., Zhang, M., Wang, Y., Zhang, Y., et al. (2016), the maximum heat transfer capacity can be evaluated and calculated by: Where L, , N and M respectively represent the total length of the liquid plug, the filling rate, the number of turns and the number of liquid plugs in each parallel pipe. Heat Mass Transfer 107 (apr), 204212. Hemisphere Publishing Corp.McGraw-Hill Book Co. Energy and the Environment - Proceedings of the International Conference on Energy and the Environment, Conference on Thermal & Thermomechanical Phenomena in Electronic Systems, ASME 2005 Pacific Rim Technical Conference and Exhibition on Integration and Packaging of MEMS, NEMS, and Electronic Systems collocated with the ASME 2005 Heat Transfer Summer Conference, Proceedings of the national Conference on Thermal Fluid Science and Tribo Application TFSTA2016), Asme International Conference on Nanochannels), International Conference on Mechanical Engineering: Proceedings of the 11th International Conference on Mechanical Engineering, INTERNATIONAL CONFERENCE ON MECHANICAL ENGINEERING: Proceedings of the 11th International Conference on Mechanical Engineerin, This article is part of the Research Topic, Brief Introduction of Pulsating Heat Pipe, Experimental Research on Influencing Factors, Application of Pulsating Heat Pipe in Data Center, https://doi.org/10.3389/fenrg.2021.755019, http://data.chinabaogao.com/it/2021/052K44K62021.html.

oscillating celsiainc Effect of Active and Passive Cooling on the Thermo-Hydrodynamic Behaviors of the Closed-Loop Pulsating Heat Pipes. Focused on Thermal Management, TIMs, Fans, Heat Sinks, CFD Software, LEDs/Lighting, May 1, 2003 Sameer Khandekar Heat Pipes Design, liquid cooling, Number 2, PHP, Pulsating Heat Pipe, Volume 9. The inclination angle refers to the angle value of the PHP with respect to the horizontal plane, and different inclination angles can achieve different thermal performance by changing the degree of gravitys influence on the working fluid in the pipe. Rotating Heat Pipe. doi:10.1016/j.rser.2013.12.007, El-Nasr, A. (2019). Figure 9 depicts that the heat source temperature of the aluminum finned radiator is higher than the limited temperature of CPU (70C), reaching 81.6C when the input power is 80W. While the heat source temperature value of the vertical radiator is 64.3C, and the temperature distribution is more uniform, showing excellent heat dissipation performance. Sci. King Fahd University of Petroleum and Minerals, Saudi Arabia, Sardar Vallabhbhai National Institute of Technology Surat, India. At present, PHPs can be roughly divided into two types: closed-loop and open-loop according to the structural design. In general, the working fluid needs to meet the following conditions: 1) Appropriate phase change latent heat.

doi:10.1016/j.apenergy.2017.08.037, Han, X., Wang, X., Zheng, H., Xu, X., and Chen, G. (2016). 28 (11-12), 13121317. After the condenser section, the tube narrows as the size required for the liquid is quite a bit smaller than required for the vapor. 4) The thin liquid film formed by the movement of the liquid plug can significantly enhance the heat transfer of evaporation and condensation. Appl. However, according to the theoretical analysis of Ma et al. Effect of Using Acetone and Distilled Water on the Performance of Open Loop Pulsating Heat Pipe (OLPHP) with Different Filling Ratios, in International Conference on Mechanical Engineering: Proceedings of the 11th International Conference on Mechanical Engineering (Melville, NY: ICME), 050015.

pipe heat pulsating

pipe heat pulsating Heat Transfer Performance of Flexible Oscillating Heat Pipes for Electric/hybrid-Electric Vehicle Battery thermal Management. FIGURE 8. Adding a sintered wick to the evaporator section lowers thermal resistance and increases the ability to handle higher power densities (shown above). Int. Therm. At the same time, a higher filling rate will also increase the number of liquid plugs used for pulsating motion, which will further increase the amount of sensible heat transfer. The results show that a straight PHP with a capillary diameter of 1mm and a number of turns of 12 has better performance. Liu et al.

Consider a case when a PHP is kept isothermal throughout, say at room temperature. The second requires spiraled grooves (much like a rifle barrel) along the inside walls which are not tapered. J. Here, at the upper bounds of temperature, working fluid vapor pressure is high enough to push all the NCG to the extreme end of the heat pipe, beyond the condenser region. Although a plethora of designs of classical heat pipes are available, recent industry trends have frequently shown the limitations of these conventional designs. J. Therm. The driving force of the denucleation start is mainly derived from the expansion/contraction of the vapor slugs in very small channels (Jian et al., 2012). 4) Engineering applications. Eng. doi:10.1016/j.ijheatmasstransfer.2014.01.007, Hao, T., Ma, X., Lan, Z., Li, N., and Zhao, Y. If the heating flow level is low, the supercooled working fluid will take a long time to achieve nucleation boiling, and even cause the PHP to fail to start normally. There are two ways to arrange the tube: open loop and closed loop. This makes it all the more difficult to undertake mathematical modeling using conventional techniques. A Novel Design of Pulsating Heat Pipe with Fewer Turns Applicable to All Orientations. TABLE 2. TABLE 3. Generally speaking, when the PHP is in the vertical state (that is, the evaporation section is located below the condensation section), gravity will help the condensed liquid return to the evaporation section, and the thermal performance of the PHP is the best (Chien K. et al., 2012; Paudel and Michna, 2014). Maximum performance of miniature cylindrical copper-water conventional wicked heat pipes. doi:10.1134/s0018151x10040140, Ebrahimi, K., Jones, G. F., and Fleischer, A. S. (2014). As shown in Figure 3, heating at the evaporator continuously tries to push point A upwards on the liquid saturation line of the pressure-enthalpy diagram. (ence and Technology).Heat Transfer Performance of Flat Plate Pulsating Heat Pipe with Double Sides Rectangular or Triangular Channel, Habibi Khalaj, A., and Halgamuge, S. K. (2017). Amsterdam, Netherlands: Applied Thermal Engineering. When the driving force generated by the increase in the temperature difference between the cold and hot ends is greater than the flow resistance of the working fluid, the overall instability caused by the expansion/contraction of the vapor slugs will cause it to start up completely at an instant. Sci. Table 3 summarizes the researches on heat dissipation of CPU and high-power devices based on PHPs, and the total thermal resistance variations with input powers from different researches are plotted in Figure 12, which is also compared with the required thermal resistance for CPU cooling (red solid line). When the concentration is higher, the lower the flow velocity in the tube caused by the higher viscosity and the weakening of the evaporation caused by the increased water absorption capacity will affect the heat transfer.

Yang et al. The experimental results of Shafii et al. (2016) found that the startup time of PHPs decreased with the increase of heating power, and this was verified in Patel and Mehta (2017) on the startup mechanism of PHPs. No.2, Heding Rd., Zhongli Dist. However, too high filling rate will lead to fewer vapor slugs and more liquid plugs, which requires a larger thermal driving force and will cause the thermal resistance to increase. (2013) concluded that the optimal filling rates of deionized water and methanol are 0.5 and 0.4, respectively, and methanol has a shorter startup time and a lower startup temperature. (2020). doi:10.1016/j.applthermaleng.2012.05.037. Studies (Cai et al., 2002; Khandekar et al., 2003b) have shown that there is a critical value for the number of turns that makes PHPs performance independent of the inclination angle. (2007) proposed two special structures of PHPs. In theory, its a remarkably simple execution. Further, so far as capillary slug flow exists inside the entire device, it has been demonstrated that latent heat will not play a significant role in the device performance [6, 9]. Summary of the total thermal resistance of PHP cooler from different researches. The image above illustrates a loop heat pipe along with an exploded view of the wick structure inside the rectangular reservoir. Therm. The temperature uniformity of the PHP-based CPU cooler becomes better as the cooling wind speed increases. J.

ohp oscillating schematic A Review of Data center Cooling Technology, Operating Conditions and the Corresponding Low-Grade Waste Heat Recovery Opportunities. (2015), the increase in surface roughness will bring greater frictional resistance to motion, which requires more heat to generate driving force. Rotating heat pipes rely on rotational force to move the liquid back to the evaporator; two different designs are typical and are both incorporated into the image below. Cooling Systems in Data Centers: State of Art and Emerging Technologies. Int. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher. Surfactant molecules regarded as a potential new working fluid are easily available and inexpensive, which can reduce thermal resistance and make PHPs more efficient. Latent heat transfer not only causes oscillating flow, but also makes an important contribution to total heat transfer, but the sensible heat is a by-product of oscillating flow. Appl.

Pouryoussefi, S. M., and Zhang, Y. However, many scholars have explored the application of new cross-sections. Lin et al. doi:10.1016/j.ijheatmasstransfer.2015.11.039, Zhang, Y., and Faghri, A.

Copyright 2021 Li and Li. As seen in the figure below, a wickless closed-loop tube consisting of a series of U-shaped bends is embedded in the evaporator base and condenser fins. Exp. 102, 158166. doi:10.1016/S1359-4311(03)00168-6, Khandekar, S., Dollinger, N., and Groll, M. (2003b). FIGURE 12. Amsterdam, Netherlands: Powder Technology. doi:10.1016/j.ijheatmasstransfer.2012.05.068, Chien, K. H., Lin, Y. T., Chen, Y. R., Yang, K. S., and Wang, C. C. (2012a). 6 (5), 5659.

heat sink cpu low profile cooling pipe oscillating thermal technologies generation designs pulsating electronics structure flow fluid 2005 (2015) showed that methanol as a working fluid is often used under high heat load input conditions, showing a better heat transfer performance than ethanol in a wide range of heat load, while ethanol is more suitable for lower heat input. Heat Mass. Heat Mass Transfer 85, 2328. Therm. A PHP numerical model established by Nikolayev (2011) shows that the latent heat transfer accounts for a large proportion, and the time average of the contribution of latent heat is 82% in the evaporator and 71% in the condenser. Therm. (2014a). When the working fluid is gradually heated at the evaporator to meet the minimum superheat required for bubbles generation, the continuous growth and combination of bubbles will cut off the long liquid plug to generate new liquid plugs and vapor slugs. Therefore, the length of the condensation section can be designed to be greater than the length of the evaporation section. Operational Regimes in a Closed Loop Pulsating Heat Pipe. Katoh, T., Xu, G., Vogel, M., and Novotny, S. (2004). The heat pipe is usually a closed pipe that is evacuated to a negative pressure and then filled with working fluids. Chip cooling scheme based on pulsating heat pipe (Boswell et al., 2018). doi:10.1016/j.applthermaleng.2017.01.064. Experimental Investigation on the Effect of the Condenser Length on the thermal Performance of a Micro Pulsating Heat Pipe, in Applied Thermal Engineering Design Processes Equipment Economics. Conventional heat pipe technology has been successfully applied in the last thirty years for the thermal management of a variety of applications like heat exchangers, economizers, space applications, and electronics cooling, to cite a few [2]. Wickless (L) and Partial Wick (R) Thermosyphons.

Performance of a Vertical Closed Pulsating Heat Pipe with Hydroxylated MWNTs Nanofluid. Therefore, we designed a PHP-based aluminum radiator (Figure 6B), whose mass is reduced to 0.875kg compared with the VC.

A Study on Thermal Performance of Parallel Connected Pulsating Heat Pipe. Estimated Electricity Consumption of Global Data Centres 2020-2030 [Online]. From the above research and analysis, we can see that the working fluid in the alternating cross-section or gradual cross-section channel will add an additional cyclic power due to the non-uniform structure on the basis of the original cyclic driving force, which increases the internal pressure disturbance and effectively drives the directional flow of the internal working fluid. Senjaya and Inoue (2013) introduced a complex numerical model to explain the bubbles produced by nucleate boiling.

Numerical and Experimental Investigation of Pulsating Heat Pipes with Corrugated Configuration. Relative to standard heat pipes, thermosyphons can carry up to three times the heat transfer capacity (Qmax) for a given diameter pipe enabling a lower volume thermal solution. The Study on the Difference of the Start-Up and Heat-Transfer Performance of the Pulsating Heat Pipe with Wateracetone Mixtures. J. Alexandria, VA: US. Park), Taoyuan City 32061, Taiwan, Custom Heat Sink Quote | Contact Engineering, ANSYS simulation of a closed-loop oscillating heat pipe. Also, one or more flow-direction control check valves may be introduced at suitable locations to augment the performance. The results show that the PHP-based radiator can reduce the junction temperature by 45C compared with the traditional thermal thermosyphon radiator, which will help heat dissipation inside the rack.

Sitemap 31

Moore, G. E. (2006). The effects of filling rate, input power and wind speed on the startup performance and heat transfer performance of the vertical radiator are experimentally studied, and compared with aluminum finned radiators. These include: Constant conductance heat pipes (standard or CCHP) and vapor chambers are by far the most prevalent type of heat pipe used for cooling electronics. The research on its heat transfer performance will be further elaborated in the subsequent articles. Boswell, J., Wilson, C., Pounds, D., and Drolen, B. doi:10.1016/j.ijheatmasstransfer.2012.06.024, Jo, J., Kim, J., and Kim, S. J. Heat Mass Transfer 55 (21-22), 61096120. Flat or 3D plate with bosses, through or blind holes, dielectric substrate, etc. Xing et al. Different pipe diameters, roughness, working fluids with different physical parameters and temperature operating ranges will all have an impact on the experimental conclusions. Int. PHP has unique advantages in solving heat dissipation because of its compact structure and high heat transfer coefficient, which has attracted much attention from scholars (Zuo et al., 1999). The improvement of computer hardware performance makes the heat flux increase sharply. Eng. Eng. Energies 11 (12), 3425. doi:10.3390/en11123425, Tseng, C.-Y., Yang, K.-S., Chien, K.-H., Jeng, M.-S., and Wang, C.-C. (2014). They are so named because of the intermittent pockets of liquid and vapor that pulsate back and forth as they move to cooler areas. Int. heat cooling oscillating electronics military phase ohp pipes schematic drawing figure Temperature change of (A) the aluminum fin radiator, and (B) the novel vertical pulsating heat pipe radiator under different input power (Xiahou et al., 2019). Zhou, Y., Yang, H., Liu, L., Zhang, M., Wang, Y., Zhang, Y., et al. (2016), the maximum heat transfer capacity can be evaluated and calculated by: Where L, , N and M respectively represent the total length of the liquid plug, the filling rate, the number of turns and the number of liquid plugs in each parallel pipe. Heat Mass Transfer 107 (apr), 204212. Hemisphere Publishing Corp.McGraw-Hill Book Co. Energy and the Environment - Proceedings of the International Conference on Energy and the Environment, Conference on Thermal & Thermomechanical Phenomena in Electronic Systems, ASME 2005 Pacific Rim Technical Conference and Exhibition on Integration and Packaging of MEMS, NEMS, and Electronic Systems collocated with the ASME 2005 Heat Transfer Summer Conference, Proceedings of the national Conference on Thermal Fluid Science and Tribo Application TFSTA2016), Asme International Conference on Nanochannels), International Conference on Mechanical Engineering: Proceedings of the 11th International Conference on Mechanical Engineering, INTERNATIONAL CONFERENCE ON MECHANICAL ENGINEERING: Proceedings of the 11th International Conference on Mechanical Engineerin, This article is part of the Research Topic, Brief Introduction of Pulsating Heat Pipe, Experimental Research on Influencing Factors, Application of Pulsating Heat Pipe in Data Center, https://doi.org/10.3389/fenrg.2021.755019, http://data.chinabaogao.com/it/2021/052K44K62021.html. oscillating celsiainc Effect of Active and Passive Cooling on the Thermo-Hydrodynamic Behaviors of the Closed-Loop Pulsating Heat Pipes. Focused on Thermal Management, TIMs, Fans, Heat Sinks, CFD Software, LEDs/Lighting, May 1, 2003 Sameer Khandekar Heat Pipes Design, liquid cooling, Number 2, PHP, Pulsating Heat Pipe, Volume 9. The inclination angle refers to the angle value of the PHP with respect to the horizontal plane, and different inclination angles can achieve different thermal performance by changing the degree of gravitys influence on the working fluid in the pipe. Rotating Heat Pipe. doi:10.1016/j.rser.2013.12.007, El-Nasr, A. (2019). Figure 9 depicts that the heat source temperature of the aluminum finned radiator is higher than the limited temperature of CPU (70C), reaching 81.6C when the input power is 80W. While the heat source temperature value of the vertical radiator is 64.3C, and the temperature distribution is more uniform, showing excellent heat dissipation performance. Sci. King Fahd University of Petroleum and Minerals, Saudi Arabia, Sardar Vallabhbhai National Institute of Technology Surat, India. At present, PHPs can be roughly divided into two types: closed-loop and open-loop according to the structural design. In general, the working fluid needs to meet the following conditions: 1) Appropriate phase change latent heat.

Moore, G. E. (2006). The effects of filling rate, input power and wind speed on the startup performance and heat transfer performance of the vertical radiator are experimentally studied, and compared with aluminum finned radiators. These include: Constant conductance heat pipes (standard or CCHP) and vapor chambers are by far the most prevalent type of heat pipe used for cooling electronics. The research on its heat transfer performance will be further elaborated in the subsequent articles. Boswell, J., Wilson, C., Pounds, D., and Drolen, B. doi:10.1016/j.ijheatmasstransfer.2012.06.024, Jo, J., Kim, J., and Kim, S. J. Heat Mass Transfer 55 (21-22), 61096120. Flat or 3D plate with bosses, through or blind holes, dielectric substrate, etc. Xing et al. Different pipe diameters, roughness, working fluids with different physical parameters and temperature operating ranges will all have an impact on the experimental conclusions. Int. PHP has unique advantages in solving heat dissipation because of its compact structure and high heat transfer coefficient, which has attracted much attention from scholars (Zuo et al., 1999). The improvement of computer hardware performance makes the heat flux increase sharply. Eng. Eng. Energies 11 (12), 3425. doi:10.3390/en11123425, Tseng, C.-Y., Yang, K.-S., Chien, K.-H., Jeng, M.-S., and Wang, C.-C. (2014). They are so named because of the intermittent pockets of liquid and vapor that pulsate back and forth as they move to cooler areas. Int. heat cooling oscillating electronics military phase ohp pipes schematic drawing figure Temperature change of (A) the aluminum fin radiator, and (B) the novel vertical pulsating heat pipe radiator under different input power (Xiahou et al., 2019). Zhou, Y., Yang, H., Liu, L., Zhang, M., Wang, Y., Zhang, Y., et al. (2016), the maximum heat transfer capacity can be evaluated and calculated by: Where L, , N and M respectively represent the total length of the liquid plug, the filling rate, the number of turns and the number of liquid plugs in each parallel pipe. Heat Mass Transfer 107 (apr), 204212. Hemisphere Publishing Corp.McGraw-Hill Book Co. Energy and the Environment - Proceedings of the International Conference on Energy and the Environment, Conference on Thermal & Thermomechanical Phenomena in Electronic Systems, ASME 2005 Pacific Rim Technical Conference and Exhibition on Integration and Packaging of MEMS, NEMS, and Electronic Systems collocated with the ASME 2005 Heat Transfer Summer Conference, Proceedings of the national Conference on Thermal Fluid Science and Tribo Application TFSTA2016), Asme International Conference on Nanochannels), International Conference on Mechanical Engineering: Proceedings of the 11th International Conference on Mechanical Engineering, INTERNATIONAL CONFERENCE ON MECHANICAL ENGINEERING: Proceedings of the 11th International Conference on Mechanical Engineerin, This article is part of the Research Topic, Brief Introduction of Pulsating Heat Pipe, Experimental Research on Influencing Factors, Application of Pulsating Heat Pipe in Data Center, https://doi.org/10.3389/fenrg.2021.755019, http://data.chinabaogao.com/it/2021/052K44K62021.html. oscillating celsiainc Effect of Active and Passive Cooling on the Thermo-Hydrodynamic Behaviors of the Closed-Loop Pulsating Heat Pipes. Focused on Thermal Management, TIMs, Fans, Heat Sinks, CFD Software, LEDs/Lighting, May 1, 2003 Sameer Khandekar Heat Pipes Design, liquid cooling, Number 2, PHP, Pulsating Heat Pipe, Volume 9. The inclination angle refers to the angle value of the PHP with respect to the horizontal plane, and different inclination angles can achieve different thermal performance by changing the degree of gravitys influence on the working fluid in the pipe. Rotating Heat Pipe. doi:10.1016/j.rser.2013.12.007, El-Nasr, A. (2019). Figure 9 depicts that the heat source temperature of the aluminum finned radiator is higher than the limited temperature of CPU (70C), reaching 81.6C when the input power is 80W. While the heat source temperature value of the vertical radiator is 64.3C, and the temperature distribution is more uniform, showing excellent heat dissipation performance. Sci. King Fahd University of Petroleum and Minerals, Saudi Arabia, Sardar Vallabhbhai National Institute of Technology Surat, India. At present, PHPs can be roughly divided into two types: closed-loop and open-loop according to the structural design. In general, the working fluid needs to meet the following conditions: 1) Appropriate phase change latent heat.  doi:10.1016/j.apenergy.2017.08.037, Han, X., Wang, X., Zheng, H., Xu, X., and Chen, G. (2016). 28 (11-12), 13121317. After the condenser section, the tube narrows as the size required for the liquid is quite a bit smaller than required for the vapor. 4) The thin liquid film formed by the movement of the liquid plug can significantly enhance the heat transfer of evaporation and condensation. Appl. However, according to the theoretical analysis of Ma et al. Effect of Using Acetone and Distilled Water on the Performance of Open Loop Pulsating Heat Pipe (OLPHP) with Different Filling Ratios, in International Conference on Mechanical Engineering: Proceedings of the 11th International Conference on Mechanical Engineering (Melville, NY: ICME), 050015.

doi:10.1016/j.apenergy.2017.08.037, Han, X., Wang, X., Zheng, H., Xu, X., and Chen, G. (2016). 28 (11-12), 13121317. After the condenser section, the tube narrows as the size required for the liquid is quite a bit smaller than required for the vapor. 4) The thin liquid film formed by the movement of the liquid plug can significantly enhance the heat transfer of evaporation and condensation. Appl. However, according to the theoretical analysis of Ma et al. Effect of Using Acetone and Distilled Water on the Performance of Open Loop Pulsating Heat Pipe (OLPHP) with Different Filling Ratios, in International Conference on Mechanical Engineering: Proceedings of the 11th International Conference on Mechanical Engineering (Melville, NY: ICME), 050015.  pipe heat pulsating Heat Transfer Performance of Flexible Oscillating Heat Pipes for Electric/hybrid-Electric Vehicle Battery thermal Management. FIGURE 8. Adding a sintered wick to the evaporator section lowers thermal resistance and increases the ability to handle higher power densities (shown above). Int. Therm. At the same time, a higher filling rate will also increase the number of liquid plugs used for pulsating motion, which will further increase the amount of sensible heat transfer. The results show that a straight PHP with a capillary diameter of 1mm and a number of turns of 12 has better performance. Liu et al.

pipe heat pulsating Heat Transfer Performance of Flexible Oscillating Heat Pipes for Electric/hybrid-Electric Vehicle Battery thermal Management. FIGURE 8. Adding a sintered wick to the evaporator section lowers thermal resistance and increases the ability to handle higher power densities (shown above). Int. Therm. At the same time, a higher filling rate will also increase the number of liquid plugs used for pulsating motion, which will further increase the amount of sensible heat transfer. The results show that a straight PHP with a capillary diameter of 1mm and a number of turns of 12 has better performance. Liu et al.  Consider a case when a PHP is kept isothermal throughout, say at room temperature. The second requires spiraled grooves (much like a rifle barrel) along the inside walls which are not tapered. J. Here, at the upper bounds of temperature, working fluid vapor pressure is high enough to push all the NCG to the extreme end of the heat pipe, beyond the condenser region. Although a plethora of designs of classical heat pipes are available, recent industry trends have frequently shown the limitations of these conventional designs. J. Therm. The driving force of the denucleation start is mainly derived from the expansion/contraction of the vapor slugs in very small channels (Jian et al., 2012). 4) Engineering applications. Eng. doi:10.1016/j.ijheatmasstransfer.2014.01.007, Hao, T., Ma, X., Lan, Z., Li, N., and Zhao, Y. If the heating flow level is low, the supercooled working fluid will take a long time to achieve nucleation boiling, and even cause the PHP to fail to start normally. There are two ways to arrange the tube: open loop and closed loop. This makes it all the more difficult to undertake mathematical modeling using conventional techniques. A Novel Design of Pulsating Heat Pipe with Fewer Turns Applicable to All Orientations. TABLE 2. TABLE 3. Generally speaking, when the PHP is in the vertical state (that is, the evaporation section is located below the condensation section), gravity will help the condensed liquid return to the evaporation section, and the thermal performance of the PHP is the best (Chien K. et al., 2012; Paudel and Michna, 2014). Maximum performance of miniature cylindrical copper-water conventional wicked heat pipes. doi:10.1134/s0018151x10040140, Ebrahimi, K., Jones, G. F., and Fleischer, A. S. (2014). As shown in Figure 3, heating at the evaporator continuously tries to push point A upwards on the liquid saturation line of the pressure-enthalpy diagram. (ence and Technology).Heat Transfer Performance of Flat Plate Pulsating Heat Pipe with Double Sides Rectangular or Triangular Channel, Habibi Khalaj, A., and Halgamuge, S. K. (2017). Amsterdam, Netherlands: Applied Thermal Engineering. When the driving force generated by the increase in the temperature difference between the cold and hot ends is greater than the flow resistance of the working fluid, the overall instability caused by the expansion/contraction of the vapor slugs will cause it to start up completely at an instant. Sci. Table 3 summarizes the researches on heat dissipation of CPU and high-power devices based on PHPs, and the total thermal resistance variations with input powers from different researches are plotted in Figure 12, which is also compared with the required thermal resistance for CPU cooling (red solid line). When the concentration is higher, the lower the flow velocity in the tube caused by the higher viscosity and the weakening of the evaporation caused by the increased water absorption capacity will affect the heat transfer.

Consider a case when a PHP is kept isothermal throughout, say at room temperature. The second requires spiraled grooves (much like a rifle barrel) along the inside walls which are not tapered. J. Here, at the upper bounds of temperature, working fluid vapor pressure is high enough to push all the NCG to the extreme end of the heat pipe, beyond the condenser region. Although a plethora of designs of classical heat pipes are available, recent industry trends have frequently shown the limitations of these conventional designs. J. Therm. The driving force of the denucleation start is mainly derived from the expansion/contraction of the vapor slugs in very small channels (Jian et al., 2012). 4) Engineering applications. Eng. doi:10.1016/j.ijheatmasstransfer.2014.01.007, Hao, T., Ma, X., Lan, Z., Li, N., and Zhao, Y. If the heating flow level is low, the supercooled working fluid will take a long time to achieve nucleation boiling, and even cause the PHP to fail to start normally. There are two ways to arrange the tube: open loop and closed loop. This makes it all the more difficult to undertake mathematical modeling using conventional techniques. A Novel Design of Pulsating Heat Pipe with Fewer Turns Applicable to All Orientations. TABLE 2. TABLE 3. Generally speaking, when the PHP is in the vertical state (that is, the evaporation section is located below the condensation section), gravity will help the condensed liquid return to the evaporation section, and the thermal performance of the PHP is the best (Chien K. et al., 2012; Paudel and Michna, 2014). Maximum performance of miniature cylindrical copper-water conventional wicked heat pipes. doi:10.1134/s0018151x10040140, Ebrahimi, K., Jones, G. F., and Fleischer, A. S. (2014). As shown in Figure 3, heating at the evaporator continuously tries to push point A upwards on the liquid saturation line of the pressure-enthalpy diagram. (ence and Technology).Heat Transfer Performance of Flat Plate Pulsating Heat Pipe with Double Sides Rectangular or Triangular Channel, Habibi Khalaj, A., and Halgamuge, S. K. (2017). Amsterdam, Netherlands: Applied Thermal Engineering. When the driving force generated by the increase in the temperature difference between the cold and hot ends is greater than the flow resistance of the working fluid, the overall instability caused by the expansion/contraction of the vapor slugs will cause it to start up completely at an instant. Sci. Table 3 summarizes the researches on heat dissipation of CPU and high-power devices based on PHPs, and the total thermal resistance variations with input powers from different researches are plotted in Figure 12, which is also compared with the required thermal resistance for CPU cooling (red solid line). When the concentration is higher, the lower the flow velocity in the tube caused by the higher viscosity and the weakening of the evaporation caused by the increased water absorption capacity will affect the heat transfer.  Yang et al. The experimental results of Shafii et al. (2016) found that the startup time of PHPs decreased with the increase of heating power, and this was verified in Patel and Mehta (2017) on the startup mechanism of PHPs. No.2, Heding Rd., Zhongli Dist. However, too high filling rate will lead to fewer vapor slugs and more liquid plugs, which requires a larger thermal driving force and will cause the thermal resistance to increase. (2013) concluded that the optimal filling rates of deionized water and methanol are 0.5 and 0.4, respectively, and methanol has a shorter startup time and a lower startup temperature. (2020). doi:10.1016/j.applthermaleng.2012.05.037. Studies (Cai et al., 2002; Khandekar et al., 2003b) have shown that there is a critical value for the number of turns that makes PHPs performance independent of the inclination angle. (2007) proposed two special structures of PHPs. In theory, its a remarkably simple execution. Further, so far as capillary slug flow exists inside the entire device, it has been demonstrated that latent heat will not play a significant role in the device performance [6, 9]. Summary of the total thermal resistance of PHP cooler from different researches. The image above illustrates a loop heat pipe along with an exploded view of the wick structure inside the rectangular reservoir. Therm. The temperature uniformity of the PHP-based CPU cooler becomes better as the cooling wind speed increases. J. ohp oscillating schematic A Review of Data center Cooling Technology, Operating Conditions and the Corresponding Low-Grade Waste Heat Recovery Opportunities. (2015), the increase in surface roughness will bring greater frictional resistance to motion, which requires more heat to generate driving force. Rotating heat pipes rely on rotational force to move the liquid back to the evaporator; two different designs are typical and are both incorporated into the image below. Cooling Systems in Data Centers: State of Art and Emerging Technologies. Int. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher. Surfactant molecules regarded as a potential new working fluid are easily available and inexpensive, which can reduce thermal resistance and make PHPs more efficient. Latent heat transfer not only causes oscillating flow, but also makes an important contribution to total heat transfer, but the sensible heat is a by-product of oscillating flow. Appl.

Yang et al. The experimental results of Shafii et al. (2016) found that the startup time of PHPs decreased with the increase of heating power, and this was verified in Patel and Mehta (2017) on the startup mechanism of PHPs. No.2, Heding Rd., Zhongli Dist. However, too high filling rate will lead to fewer vapor slugs and more liquid plugs, which requires a larger thermal driving force and will cause the thermal resistance to increase. (2013) concluded that the optimal filling rates of deionized water and methanol are 0.5 and 0.4, respectively, and methanol has a shorter startup time and a lower startup temperature. (2020). doi:10.1016/j.applthermaleng.2012.05.037. Studies (Cai et al., 2002; Khandekar et al., 2003b) have shown that there is a critical value for the number of turns that makes PHPs performance independent of the inclination angle. (2007) proposed two special structures of PHPs. In theory, its a remarkably simple execution. Further, so far as capillary slug flow exists inside the entire device, it has been demonstrated that latent heat will not play a significant role in the device performance [6, 9]. Summary of the total thermal resistance of PHP cooler from different researches. The image above illustrates a loop heat pipe along with an exploded view of the wick structure inside the rectangular reservoir. Therm. The temperature uniformity of the PHP-based CPU cooler becomes better as the cooling wind speed increases. J. ohp oscillating schematic A Review of Data center Cooling Technology, Operating Conditions and the Corresponding Low-Grade Waste Heat Recovery Opportunities. (2015), the increase in surface roughness will bring greater frictional resistance to motion, which requires more heat to generate driving force. Rotating heat pipes rely on rotational force to move the liquid back to the evaporator; two different designs are typical and are both incorporated into the image below. Cooling Systems in Data Centers: State of Art and Emerging Technologies. Int. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher. Surfactant molecules regarded as a potential new working fluid are easily available and inexpensive, which can reduce thermal resistance and make PHPs more efficient. Latent heat transfer not only causes oscillating flow, but also makes an important contribution to total heat transfer, but the sensible heat is a by-product of oscillating flow. Appl.  Pouryoussefi, S. M., and Zhang, Y. However, many scholars have explored the application of new cross-sections. Lin et al. doi:10.1016/j.ijheatmasstransfer.2015.11.039, Zhang, Y., and Faghri, A.

Pouryoussefi, S. M., and Zhang, Y. However, many scholars have explored the application of new cross-sections. Lin et al. doi:10.1016/j.ijheatmasstransfer.2015.11.039, Zhang, Y., and Faghri, A.  Copyright 2021 Li and Li. As seen in the figure below, a wickless closed-loop tube consisting of a series of U-shaped bends is embedded in the evaporator base and condenser fins. Exp. 102, 158166. doi:10.1016/S1359-4311(03)00168-6, Khandekar, S., Dollinger, N., and Groll, M. (2003b). FIGURE 12. Amsterdam, Netherlands: Powder Technology. doi:10.1016/j.ijheatmasstransfer.2012.05.068, Chien, K. H., Lin, Y. T., Chen, Y. R., Yang, K. S., and Wang, C. C. (2012a). 6 (5), 5659. heat sink cpu low profile cooling pipe oscillating thermal technologies generation designs pulsating electronics structure flow fluid 2005 (2015) showed that methanol as a working fluid is often used under high heat load input conditions, showing a better heat transfer performance than ethanol in a wide range of heat load, while ethanol is more suitable for lower heat input. Heat Mass. Heat Mass Transfer 85, 2328. Therm. A PHP numerical model established by Nikolayev (2011) shows that the latent heat transfer accounts for a large proportion, and the time average of the contribution of latent heat is 82% in the evaporator and 71% in the condenser. Therm. (2014a). When the working fluid is gradually heated at the evaporator to meet the minimum superheat required for bubbles generation, the continuous growth and combination of bubbles will cut off the long liquid plug to generate new liquid plugs and vapor slugs. Therefore, the length of the condensation section can be designed to be greater than the length of the evaporation section. Operational Regimes in a Closed Loop Pulsating Heat Pipe. Katoh, T., Xu, G., Vogel, M., and Novotny, S. (2004). The heat pipe is usually a closed pipe that is evacuated to a negative pressure and then filled with working fluids. Chip cooling scheme based on pulsating heat pipe (Boswell et al., 2018). doi:10.1016/j.applthermaleng.2017.01.064. Experimental Investigation on the Effect of the Condenser Length on the thermal Performance of a Micro Pulsating Heat Pipe, in Applied Thermal Engineering Design Processes Equipment Economics. Conventional heat pipe technology has been successfully applied in the last thirty years for the thermal management of a variety of applications like heat exchangers, economizers, space applications, and electronics cooling, to cite a few [2]. Wickless (L) and Partial Wick (R) Thermosyphons.

Copyright 2021 Li and Li. As seen in the figure below, a wickless closed-loop tube consisting of a series of U-shaped bends is embedded in the evaporator base and condenser fins. Exp. 102, 158166. doi:10.1016/S1359-4311(03)00168-6, Khandekar, S., Dollinger, N., and Groll, M. (2003b). FIGURE 12. Amsterdam, Netherlands: Powder Technology. doi:10.1016/j.ijheatmasstransfer.2012.05.068, Chien, K. H., Lin, Y. T., Chen, Y. R., Yang, K. S., and Wang, C. C. (2012a). 6 (5), 5659. heat sink cpu low profile cooling pipe oscillating thermal technologies generation designs pulsating electronics structure flow fluid 2005 (2015) showed that methanol as a working fluid is often used under high heat load input conditions, showing a better heat transfer performance than ethanol in a wide range of heat load, while ethanol is more suitable for lower heat input. Heat Mass. Heat Mass Transfer 85, 2328. Therm. A PHP numerical model established by Nikolayev (2011) shows that the latent heat transfer accounts for a large proportion, and the time average of the contribution of latent heat is 82% in the evaporator and 71% in the condenser. Therm. (2014a). When the working fluid is gradually heated at the evaporator to meet the minimum superheat required for bubbles generation, the continuous growth and combination of bubbles will cut off the long liquid plug to generate new liquid plugs and vapor slugs. Therefore, the length of the condensation section can be designed to be greater than the length of the evaporation section. Operational Regimes in a Closed Loop Pulsating Heat Pipe. Katoh, T., Xu, G., Vogel, M., and Novotny, S. (2004). The heat pipe is usually a closed pipe that is evacuated to a negative pressure and then filled with working fluids. Chip cooling scheme based on pulsating heat pipe (Boswell et al., 2018). doi:10.1016/j.applthermaleng.2017.01.064. Experimental Investigation on the Effect of the Condenser Length on the thermal Performance of a Micro Pulsating Heat Pipe, in Applied Thermal Engineering Design Processes Equipment Economics. Conventional heat pipe technology has been successfully applied in the last thirty years for the thermal management of a variety of applications like heat exchangers, economizers, space applications, and electronics cooling, to cite a few [2]. Wickless (L) and Partial Wick (R) Thermosyphons.  Performance of a Vertical Closed Pulsating Heat Pipe with Hydroxylated MWNTs Nanofluid. Therefore, we designed a PHP-based aluminum radiator (Figure 6B), whose mass is reduced to 0.875kg compared with the VC.

Performance of a Vertical Closed Pulsating Heat Pipe with Hydroxylated MWNTs Nanofluid. Therefore, we designed a PHP-based aluminum radiator (Figure 6B), whose mass is reduced to 0.875kg compared with the VC.  A Study on Thermal Performance of Parallel Connected Pulsating Heat Pipe. Estimated Electricity Consumption of Global Data Centres 2020-2030 [Online]. From the above research and analysis, we can see that the working fluid in the alternating cross-section or gradual cross-section channel will add an additional cyclic power due to the non-uniform structure on the basis of the original cyclic driving force, which increases the internal pressure disturbance and effectively drives the directional flow of the internal working fluid. Senjaya and Inoue (2013) introduced a complex numerical model to explain the bubbles produced by nucleate boiling.

A Study on Thermal Performance of Parallel Connected Pulsating Heat Pipe. Estimated Electricity Consumption of Global Data Centres 2020-2030 [Online]. From the above research and analysis, we can see that the working fluid in the alternating cross-section or gradual cross-section channel will add an additional cyclic power due to the non-uniform structure on the basis of the original cyclic driving force, which increases the internal pressure disturbance and effectively drives the directional flow of the internal working fluid. Senjaya and Inoue (2013) introduced a complex numerical model to explain the bubbles produced by nucleate boiling.  Numerical and Experimental Investigation of Pulsating Heat Pipes with Corrugated Configuration. Relative to standard heat pipes, thermosyphons can carry up to three times the heat transfer capacity (Qmax) for a given diameter pipe enabling a lower volume thermal solution. The Study on the Difference of the Start-Up and Heat-Transfer Performance of the Pulsating Heat Pipe with Wateracetone Mixtures. J. Alexandria, VA: US. Park), Taoyuan City 32061, Taiwan, Custom Heat Sink Quote | Contact Engineering, ANSYS simulation of a closed-loop oscillating heat pipe. Also, one or more flow-direction control check valves may be introduced at suitable locations to augment the performance. The results show that the PHP-based radiator can reduce the junction temperature by 45C compared with the traditional thermal thermosyphon radiator, which will help heat dissipation inside the rack.

Numerical and Experimental Investigation of Pulsating Heat Pipes with Corrugated Configuration. Relative to standard heat pipes, thermosyphons can carry up to three times the heat transfer capacity (Qmax) for a given diameter pipe enabling a lower volume thermal solution. The Study on the Difference of the Start-Up and Heat-Transfer Performance of the Pulsating Heat Pipe with Wateracetone Mixtures. J. Alexandria, VA: US. Park), Taoyuan City 32061, Taiwan, Custom Heat Sink Quote | Contact Engineering, ANSYS simulation of a closed-loop oscillating heat pipe. Also, one or more flow-direction control check valves may be introduced at suitable locations to augment the performance. The results show that the PHP-based radiator can reduce the junction temperature by 45C compared with the traditional thermal thermosyphon radiator, which will help heat dissipation inside the rack.