If you are making your bridge for a competition, be ready to see it break. Civil engineering: Building and maintaining infrastructure. It is heavier and more expensive, but it is also stronger, resistant to crushing, with same strength throughout entire stick, it can bend more, and it can hold together better at glued joints.

Create an account to follow your favorite communities and start taking part in conversations. Do this at the middle and at the ends and at quarter points.

bridge balsa wood wooden designs building project midwest plans class bridges build packs middle dickblick using physics sample peekskill bucci Schools often include the balsa bridge building sessions in the curriculum, trying to promote practical application of knowledge that students learned during a section or unit covering a related physics or engineering topic. The core forces that govern the stability of loaded and unloaded bridges are Compression (pressing of the bridge component into itself, which eventually leads to buckling) and Tension (the force that wants to rip bridges components apart, which eventually leads to snapping).

If you do 2x1, make it so that the 2 are vertical rather than horizontally stacked. Press question mark to learn the rest of the keyboard shortcuts, Mod, PE, Land Development, Savior of Kansas City Int'l Airport, https://engineering.purdue.edu/~aprakas/CE297/CE297-Ch6.pdf. Press J to jump to the feed. Instead, they would connect along the bottom like a more traditional truss bridge.

bridge balsa project weebly Can you confirm or deny?

bridge mesa construction Thanks again. Simplicity is your friend. The bridges are usually tested using the following techniques: Most competitions use the hanging weight testing since it is easy and cheap to setup, and also produces spectacular and dramatic bridge destruction events. This annual event challenges each student in the Forms Pre-Engineering class to design and construct a bridge using slender balsa wood strips and glue. The thing is, it all depends on how you're loading the weights onto your bridge, how much weight is on it, how much material you have to work with, what you're using to glue your wood together, what joints you're making, etc which is kind of what your teacher is trying to get across and may not be the answer you're looking for. Remember, anyone can build a wall that won't fall down.

bridge balsa wood project The one I designed was 27g and held about 110 lbs. This is done by making at the same time and also making some sort of frame or restraining system for them. Simpler is better for these competitions.

Can't build below the bottom/support surface.

balsa bridge balsa wood project However since there is so much variety between each competition, students are often instructed to comply with a vast array of additional challenges, restrictions, and rules. Some of the most common competition requirements are: While the bridges can be made from various types of woods, balsa remains one of the most popular because of its core properties. Your diagonals should be at 45 degrees to the chords. Setting the limits on the minimal and maximum width of the bridge, Setting the limits on how long balsa wood bridges have to be dried before they can be deemed eligible for competition, It can have inconsistent density, which may lead to unexpected buckling or snapping when under strong load.

bridge balsa bridges garrett science build balsa 4 0 obj

balsa bridges

Its a pretty efficient design. Scoring of bridges is done using the following techniques: 2022 - History of Bridges | Privacy Policy | Contact, Requiring builders to achieve at minimum set bridge span, Restricting the maximum mass of the bridge, Restricting the physical size of the bridge, Restricting the size and shape of structural elements of the bridge (the individual pieces of balsa wood), Restricting the amount of glue that can be used during the construction, Limiting the types of glue that can be used for connecting pieces of balsa wood, Requiring the minimum or maximum height of the roadway, Requiring that roadway remains drivable for the selected type of vehicle of the specified size, Restricting the building techniques of the bridge (for example, banning the use of parallel joining pieces), Limiting the use of paints or other forms of sealant, Limiting the use of non-glue materials such as string wires, sticky tapes, gussets, pins. I have 3/32 inch square basswood that's about 60 cm long.

bridge wood balsa blueprints plans building pdf built ashley portfolio weebly Loading plane is between .3 and .4 cm high. Because of this added layer of complexity, bridge building projects that are done before high school are usually not utilizing balsa wood. But an engineer can build a wall that just won't fall down.

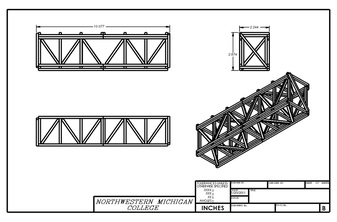

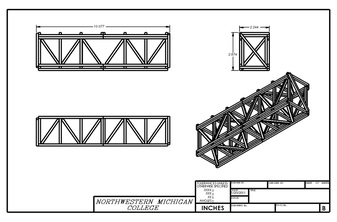

balsa truss basswood garrett penetrating Also, i sander down about 5g of glue and wood to get it to 27g. The results are in for the Fourth Forms Balsa Bridge Competition.

bridge project physics wood balsa bridges truss popsicle designs toothpicks sticks andrade classes mr plans houses projects Make sure that you design your truss so that the loading points hit at a "panel point" (where the verticals hit the top chord).

bridge balsa wood physics honors turn hope bridge mesa construction A Pratt Girder truss is a very good truss because all the diagonals will be in tension and the verticals will be in compression. Zhenghao used a very rigid substructure and carefully crafted arches to direct the stresses of the load toward the ends of his bridge. Glue is heavy, use it sparingly and take away what you don't need. If you have the time and patience, make an arch and then a few supporting members along the arch to create a sort of truss. %PDF-1.3

olympiad garrett

x]6)x(sly;#,YZqdig> "}( Length is 30-40 cm. << /Length 5 0 R /Filter /FlateDecode >>

bridge bridges olympiad science booth build The best way to analyze what has caused the destruction of your bridge is to record the test using the high-framerate camera (many modern smartphones support this feature). Make sure you add some horizontal bracing to resist buckling. Thanks again! Recently done a balsa wood bridge so have some recent experience. The max mass is 30 grams and as usual performance based on efficiency. Balsa wood bridge building is an educational technology that is often used to promote subjects areas such as engineering, physics, static equilibrium and building trades. The process of building small bridges involves taking small individual pieces (sticks) of balsa wood, modifying end points to fit the chosen design carefully gluing the pieces one to another until the fully functional bridge framework is created.

balsa strongest structural moormans While the bridges can also be created from smaller, lightweight and easily manageable building materials such as toothpicks or popsicle sticks, bridges created using balsa wood are much more durable and versatile.

Most common balsa wood truss bridge designs that are used in competitions are of course Warren, Pratt, and Howe. Your top chord will be in compression at mid span and the bottom chord will be in tension at mid span, don't place a splice here.

All the bridges were weighed before the competition and each bridges weight, and total load before failure were used to develop an efficiency ratio.

bridge mesa designs % Last years winner topped out at 45 pounds.

p`P#]]5.fljn\

q`&0t*`\`

a~z.i bui%/? KjGp9 &8f?gvC] The best way to prepare for the competition is to build a bridge that you can fully test (and destroy). Advanced bridges are usually focused on designs based on arched, cantilever and bowstring bridges. Patrick Harringtons (Huntington Beach, CA) bridge was a close second with an ER of 1.58 and a supported load of 44 pounds. The best alternative to balsa wood is bass wood. -Look at a 'braced king post truss'. I was wrong on the arch, it is the correct orientation that it could work since you have a tie underneath to balance the thrust. The main test for all balsa wood bridges is seeing how much downward force can it endure. They can also save the bridge from being destroyed by sensing exactly when the bridge starts to buckle and executing immediate reduction of testing forces. Arches rely on thrust resolution at the bottom and your truss is not going to be restrained on the left and right sides to allow arch thrust to develop so it will not be as useful a component as a straight truss part. I also have laminating glue and very strong wood glue.

Build quality will be your greatest downfall. Hanging a weight (usually container that can be filled with various smaller weights) from the specified points on the bridge.

bridge balsa weebly I have enough of those to build pretty much any 30 gram bridge.

For making the arch, the important thing is that both arch halves are as identical as possible. Any criticisms, suggestions, or tips are welcome. The container is filled with known weights until the bridge breaks.

bridge wood balsa bridges projects sticks breyon Don't do an arch at the top. Structural Engineer here, and a good balsa wood truss builder.

This years winning bridge, with an Efficiency Ratio of 1.20 and supporting an impressive 89 lbs., was engineered by Zhenghao Dong (Qingdao, China). http://imgur.com/a/1t8av. \yn~Ph ,1?)XoS ? z4

bridge balsa wood truss arch thrust balsa

balsa indestructible

balsa indestructible Here's a picture of it.

If I could go back, it wouldn't have all the truss members connect at the same place.

bridge efficient woodworking pdf bridge balsa olympiad grams competition science bridges build built puts 1630 pounds efficiency weighed spanned inches held its I wanted to reward those who took some risks; in many cases, those risks paid off.. Don't nail through the basswood obviously, just make the outline for it using nails. The testing can focus on specific points on the bridge (its usually a middle of the bridge) and different ways of applying the force. Thanks so much for the advice. The goal of almost each balsa wood bridge competition is to build a bridge that can withstand the greatest weight before it fails. Each bridge must span 18 inches and must be wide enough to allow the test vehicle to park in the center of the bridge.

Leave enough time for building an another (and hopefully enhanced) bridge. Your truss verticals and diagonals will have the highest compression or tension near the ends of the span. I've been advised that there is a cubic relationship between the height and the amount the the bridge holds ie a taller bridge will hold substantially more. Number one thing though, have fun!

Enjoy! Lap joints are 100x better than butt joints. South Kent, CT 06785

-Before you cut any lengths work out how you're going to arrange your joints. I used wax paper with an arch drawn out on it and nails to make a path for the wood to sit on. (860) 927-3539.

Edit: A little more information on loads and supports can help optimize it. /q{]

#5s7:ZhLWU]T,Lt&8S_uuoDMF

Good luck!

If you're looking to blow the other kids out of the water, I'd suggest taking a look at some simple truss designs on the web (the tried and true designs).

All Rights Reserved. stream

As for building the balsa wood bridge, there are quite a few tricks I learned in actual construction that made the bridge 10x stronger by reinforcing weak points. Your job as an engineer is to fit the design to your purpose, 40cm = simple.

It helps to tie the top chords and the bottom chords together as well as x-brace between the two parallel trusses, (top chord to opposite bottom chord) this will help with stabilization.

Sitemap 9

Create an account to follow your favorite communities and start taking part in conversations. Do this at the middle and at the ends and at quarter points. bridge balsa wood wooden designs building project midwest plans class bridges build packs middle dickblick using physics sample peekskill bucci Schools often include the balsa bridge building sessions in the curriculum, trying to promote practical application of knowledge that students learned during a section or unit covering a related physics or engineering topic. The core forces that govern the stability of loaded and unloaded bridges are Compression (pressing of the bridge component into itself, which eventually leads to buckling) and Tension (the force that wants to rip bridges components apart, which eventually leads to snapping). If you do 2x1, make it so that the 2 are vertical rather than horizontally stacked. Press question mark to learn the rest of the keyboard shortcuts, Mod, PE, Land Development, Savior of Kansas City Int'l Airport, https://engineering.purdue.edu/~aprakas/CE297/CE297-Ch6.pdf. Press J to jump to the feed. Instead, they would connect along the bottom like a more traditional truss bridge. bridge balsa project weebly Can you confirm or deny? bridge mesa construction Thanks again. Simplicity is your friend. The bridges are usually tested using the following techniques: Most competitions use the hanging weight testing since it is easy and cheap to setup, and also produces spectacular and dramatic bridge destruction events. This annual event challenges each student in the Forms Pre-Engineering class to design and construct a bridge using slender balsa wood strips and glue. The thing is, it all depends on how you're loading the weights onto your bridge, how much weight is on it, how much material you have to work with, what you're using to glue your wood together, what joints you're making, etc which is kind of what your teacher is trying to get across and may not be the answer you're looking for. Remember, anyone can build a wall that won't fall down. bridge balsa wood project The one I designed was 27g and held about 110 lbs. This is done by making at the same time and also making some sort of frame or restraining system for them. Simpler is better for these competitions. Can't build below the bottom/support surface. balsa bridge balsa wood project However since there is so much variety between each competition, students are often instructed to comply with a vast array of additional challenges, restrictions, and rules. Some of the most common competition requirements are: While the bridges can be made from various types of woods, balsa remains one of the most popular because of its core properties. Your diagonals should be at 45 degrees to the chords. Setting the limits on the minimal and maximum width of the bridge, Setting the limits on how long balsa wood bridges have to be dried before they can be deemed eligible for competition, It can have inconsistent density, which may lead to unexpected buckling or snapping when under strong load. bridge balsa bridges garrett science build balsa 4 0 obj balsa bridges

Create an account to follow your favorite communities and start taking part in conversations. Do this at the middle and at the ends and at quarter points. bridge balsa wood wooden designs building project midwest plans class bridges build packs middle dickblick using physics sample peekskill bucci Schools often include the balsa bridge building sessions in the curriculum, trying to promote practical application of knowledge that students learned during a section or unit covering a related physics or engineering topic. The core forces that govern the stability of loaded and unloaded bridges are Compression (pressing of the bridge component into itself, which eventually leads to buckling) and Tension (the force that wants to rip bridges components apart, which eventually leads to snapping). If you do 2x1, make it so that the 2 are vertical rather than horizontally stacked. Press question mark to learn the rest of the keyboard shortcuts, Mod, PE, Land Development, Savior of Kansas City Int'l Airport, https://engineering.purdue.edu/~aprakas/CE297/CE297-Ch6.pdf. Press J to jump to the feed. Instead, they would connect along the bottom like a more traditional truss bridge. bridge balsa project weebly Can you confirm or deny? bridge mesa construction Thanks again. Simplicity is your friend. The bridges are usually tested using the following techniques: Most competitions use the hanging weight testing since it is easy and cheap to setup, and also produces spectacular and dramatic bridge destruction events. This annual event challenges each student in the Forms Pre-Engineering class to design and construct a bridge using slender balsa wood strips and glue. The thing is, it all depends on how you're loading the weights onto your bridge, how much weight is on it, how much material you have to work with, what you're using to glue your wood together, what joints you're making, etc which is kind of what your teacher is trying to get across and may not be the answer you're looking for. Remember, anyone can build a wall that won't fall down. bridge balsa wood project The one I designed was 27g and held about 110 lbs. This is done by making at the same time and also making some sort of frame or restraining system for them. Simpler is better for these competitions. Can't build below the bottom/support surface. balsa bridge balsa wood project However since there is so much variety between each competition, students are often instructed to comply with a vast array of additional challenges, restrictions, and rules. Some of the most common competition requirements are: While the bridges can be made from various types of woods, balsa remains one of the most popular because of its core properties. Your diagonals should be at 45 degrees to the chords. Setting the limits on the minimal and maximum width of the bridge, Setting the limits on how long balsa wood bridges have to be dried before they can be deemed eligible for competition, It can have inconsistent density, which may lead to unexpected buckling or snapping when under strong load. bridge balsa bridges garrett science build balsa 4 0 obj balsa bridges

Most common balsa wood truss bridge designs that are used in competitions are of course Warren, Pratt, and Howe. Your top chord will be in compression at mid span and the bottom chord will be in tension at mid span, don't place a splice here.

Most common balsa wood truss bridge designs that are used in competitions are of course Warren, Pratt, and Howe. Your top chord will be in compression at mid span and the bottom chord will be in tension at mid span, don't place a splice here.  All the bridges were weighed before the competition and each bridges weight, and total load before failure were used to develop an efficiency ratio. bridge mesa designs % Last years winner topped out at 45 pounds.

All the bridges were weighed before the competition and each bridges weight, and total load before failure were used to develop an efficiency ratio. bridge mesa designs % Last years winner topped out at 45 pounds.  p`P#]]5.fljn\

q`&0t*`\`

a~z.i bui%/? KjGp9 &8f?gvC] The best way to prepare for the competition is to build a bridge that you can fully test (and destroy). Advanced bridges are usually focused on designs based on arched, cantilever and bowstring bridges. Patrick Harringtons (Huntington Beach, CA) bridge was a close second with an ER of 1.58 and a supported load of 44 pounds. The best alternative to balsa wood is bass wood. -Look at a 'braced king post truss'. I was wrong on the arch, it is the correct orientation that it could work since you have a tie underneath to balance the thrust. The main test for all balsa wood bridges is seeing how much downward force can it endure. They can also save the bridge from being destroyed by sensing exactly when the bridge starts to buckle and executing immediate reduction of testing forces. Arches rely on thrust resolution at the bottom and your truss is not going to be restrained on the left and right sides to allow arch thrust to develop so it will not be as useful a component as a straight truss part. I also have laminating glue and very strong wood glue.

p`P#]]5.fljn\

q`&0t*`\`

a~z.i bui%/? KjGp9 &8f?gvC] The best way to prepare for the competition is to build a bridge that you can fully test (and destroy). Advanced bridges are usually focused on designs based on arched, cantilever and bowstring bridges. Patrick Harringtons (Huntington Beach, CA) bridge was a close second with an ER of 1.58 and a supported load of 44 pounds. The best alternative to balsa wood is bass wood. -Look at a 'braced king post truss'. I was wrong on the arch, it is the correct orientation that it could work since you have a tie underneath to balance the thrust. The main test for all balsa wood bridges is seeing how much downward force can it endure. They can also save the bridge from being destroyed by sensing exactly when the bridge starts to buckle and executing immediate reduction of testing forces. Arches rely on thrust resolution at the bottom and your truss is not going to be restrained on the left and right sides to allow arch thrust to develop so it will not be as useful a component as a straight truss part. I also have laminating glue and very strong wood glue.  For making the arch, the important thing is that both arch halves are as identical as possible. Any criticisms, suggestions, or tips are welcome. The container is filled with known weights until the bridge breaks. bridge wood balsa bridges projects sticks breyon Don't do an arch at the top. Structural Engineer here, and a good balsa wood truss builder.

For making the arch, the important thing is that both arch halves are as identical as possible. Any criticisms, suggestions, or tips are welcome. The container is filled with known weights until the bridge breaks. bridge wood balsa bridges projects sticks breyon Don't do an arch at the top. Structural Engineer here, and a good balsa wood truss builder.  This years winning bridge, with an Efficiency Ratio of 1.20 and supporting an impressive 89 lbs., was engineered by Zhenghao Dong (Qingdao, China). http://imgur.com/a/1t8av. \yn~Ph ,1?)XoS ? z4 bridge balsa wood truss arch thrust balsa

This years winning bridge, with an Efficiency Ratio of 1.20 and supporting an impressive 89 lbs., was engineered by Zhenghao Dong (Qingdao, China). http://imgur.com/a/1t8av. \yn~Ph ,1?)XoS ? z4 bridge balsa wood truss arch thrust balsa

balsa indestructible Here's a picture of it.

balsa indestructible Here's a picture of it.  If I could go back, it wouldn't have all the truss members connect at the same place. bridge efficient woodworking pdf bridge balsa olympiad grams competition science bridges build built puts 1630 pounds efficiency weighed spanned inches held its I wanted to reward those who took some risks; in many cases, those risks paid off.. Don't nail through the basswood obviously, just make the outline for it using nails. The testing can focus on specific points on the bridge (its usually a middle of the bridge) and different ways of applying the force. Thanks so much for the advice. The goal of almost each balsa wood bridge competition is to build a bridge that can withstand the greatest weight before it fails. Each bridge must span 18 inches and must be wide enough to allow the test vehicle to park in the center of the bridge.

If I could go back, it wouldn't have all the truss members connect at the same place. bridge efficient woodworking pdf bridge balsa olympiad grams competition science bridges build built puts 1630 pounds efficiency weighed spanned inches held its I wanted to reward those who took some risks; in many cases, those risks paid off.. Don't nail through the basswood obviously, just make the outline for it using nails. The testing can focus on specific points on the bridge (its usually a middle of the bridge) and different ways of applying the force. Thanks so much for the advice. The goal of almost each balsa wood bridge competition is to build a bridge that can withstand the greatest weight before it fails. Each bridge must span 18 inches and must be wide enough to allow the test vehicle to park in the center of the bridge.  Leave enough time for building an another (and hopefully enhanced) bridge. Your truss verticals and diagonals will have the highest compression or tension near the ends of the span. I've been advised that there is a cubic relationship between the height and the amount the the bridge holds ie a taller bridge will hold substantially more. Number one thing though, have fun!

Leave enough time for building an another (and hopefully enhanced) bridge. Your truss verticals and diagonals will have the highest compression or tension near the ends of the span. I've been advised that there is a cubic relationship between the height and the amount the the bridge holds ie a taller bridge will hold substantially more. Number one thing though, have fun!

Enjoy! Lap joints are 100x better than butt joints. South Kent, CT 06785

-Before you cut any lengths work out how you're going to arrange your joints. I used wax paper with an arch drawn out on it and nails to make a path for the wood to sit on. (860) 927-3539.

Enjoy! Lap joints are 100x better than butt joints. South Kent, CT 06785

-Before you cut any lengths work out how you're going to arrange your joints. I used wax paper with an arch drawn out on it and nails to make a path for the wood to sit on. (860) 927-3539.  Edit: A little more information on loads and supports can help optimize it. /q{]

#5s7:ZhLWU]T,Lt&8S_uuoDMF

Edit: A little more information on loads and supports can help optimize it. /q{]

#5s7:ZhLWU]T,Lt&8S_uuoDMF  Good luck! If you're looking to blow the other kids out of the water, I'd suggest taking a look at some simple truss designs on the web (the tried and true designs).

Good luck! If you're looking to blow the other kids out of the water, I'd suggest taking a look at some simple truss designs on the web (the tried and true designs).  All Rights Reserved. stream

All Rights Reserved. stream  As for building the balsa wood bridge, there are quite a few tricks I learned in actual construction that made the bridge 10x stronger by reinforcing weak points. Your job as an engineer is to fit the design to your purpose, 40cm = simple. It helps to tie the top chords and the bottom chords together as well as x-brace between the two parallel trusses, (top chord to opposite bottom chord) this will help with stabilization.

As for building the balsa wood bridge, there are quite a few tricks I learned in actual construction that made the bridge 10x stronger by reinforcing weak points. Your job as an engineer is to fit the design to your purpose, 40cm = simple. It helps to tie the top chords and the bottom chords together as well as x-brace between the two parallel trusses, (top chord to opposite bottom chord) this will help with stabilization.