windcharger gantry 85w 71). To learns more facts and advice about a wide variety of solar related products and issues - use our built-in site searching tool below. A reasonably simple analysis is then possible that, in the limit of weak absorption, results in an analytical expression in the form. Stone of SERI (Stone, 1989), Pacific Gas & Electric (PG&E) has organized a new proposal for the photovoltaic system development, namely, Photovoltaics for Utility Scale Application (PVUSA) project, and it has awarded contracts to Energy Conversion Devices/Sovonics and Utility Power Group (UPG) for installations of 20kW each for the emerging technology portion of their field. If efficiencies of 10% can be reached on large area thin film amorphous silicon cells on inexpensive substrates, then this would be the best approach to produce low cost electricity. Based on the analyses I've seen of various project proposals, monocrystalline solar panels are typically the most economical over the life of the installation. To overcome this predicament, a multilayer structured stack is often used in the design of amorphous silicon solar cells to achieve a balance between the optical absorption and photoelectric efficiency. Light I - V characteristics of a 933 cm2 a-Si Solarex module. ScienceDirect is a registered trademark of Elsevier B.V. ScienceDirect is a registered trademark of Elsevier B.V. What is the basic component of the PV system (Photovoltaic system)? Experimentally, the instability appears not to depend systematically on hydrogen content of the material or on how tightly hydrogen is bonded.

The announced capacity for thin-film production is 20GWp for 2015 [46]. (A) For blue, short-wavelength light, recombination only takes place near the pi interface; (B) for red, long-wavelength light, recombination can take place throughout the i layer. They are among the oldest, most efficient and most dependable ways to produce electricity from the sun. In 2005, it opened its module manufacturing plant in Dorog, Hungary.

According to solar engineers I speak with even though this may be possible, there will be a slight drop off in efficiency of around 0.5% on average per year. In order to probe the far end of the cell, it is necessary to employ a bifacial configuration, in which one can let the light enter from the backi.e., through the n layerand perform EQE measurements in this arrangement [75]. 51). The standard form of HHW is __________, 18). [74], it is mainly the neutral dangling bonds that play an essential role in this part of recombination. Note: With the coming of electric cars (many of which will be introduced in the next few years), several people in the industry predict the demand for high efficiency solar panels that can help recharge their electric cars is expected to increase. 17 represents the difference between (A) blue light and (B) red light entering into a pin-type solar cell. Which Meter is used to measure the Beam Radiations ________, 4). The manufacture of amorphous silicon photovoltaic cells is based on plasma-enhanced chemical vapor deposition (PECVD), which can be used to produce silicon thin film. The Zenith Angle complement is ________, 2). Ten years later, in 1990, research on the HIT (heterojunction with intrinsic thin layer) structure was started. Monocrystalline silicon is generally created by one of several methods that involve melting high-purity, semiconductor-grade silicon (only a few parts per million of impurities) and the use of a seed to initiate the formation of a continuous single crystal. If the difference is seen at short wavelengths, it means that the collection problem occurs at the interface through which light enters into the cell (at the pi interface, for pin-cells illuminated from the p side); if it occurs at longer wavelengths, it means that the collection problem occurs in the bulk of the i layer. Furthermore, even though mono-Si cells can absorb the majority of photons within 20m of the incident surface, limitations on the ingot sawing process mean commercial wafer thickness are generally around 200m. Such efforts have been abandoned because a-SiC:H cells showed aggravated light-induced degradation, and it was not possible to increase the voltage of these cells beyond the best values achievable with optimized a-Si:H intrinsic layers (1.0V). Manufacturers of Monocrystalline Solar Panels. 44). var _gaq=_gaq||[];_gaq.push(['_setAccount','UA-20080285-1']);_gaq.push(['_trackPageview']);(function(){var ga=document.createElement('script');ga.type='text/javascript';ga.async=true;ga.src=('https:'==document.location.protocol? Some of the drawbacks of using solar cells are the efficiency is low, manufacturing is very expensive, and the wires which are used for connection is made up of silver, Solar energy protects the environment, saves your money, and the maintenance cost of solar energy is very low or we can say that almost negligible, There are two methods of solar energy utilizations they are the direct method and indirect method, The direct method of solar energy utilization can be classified into two they are solar thermal and solar photovoltaic, The water power, wind, wave energy, marine currents, OTEC, and biomass comes under the indirect method of solar energy utilization, In solar thermal energy, the efficiency range is between 20-45%, The medium temperature in the concentrating solar technologies divided into two parts they are parabolic trough collectors (PTC), and fresnel collectors, The thin bottom layer of the semiconductor in the solar cell is also called a positive type or P-type. The aim is to demonstrate that flexible thin-film silicon PV modules manufactured by means of automated roll-to-roll processes offer a versatile lightweight thin-film silicon PV product that will offer competitive kilowatt-hour costs in a wide range of applications [49]. Currently, For more information click here. What is the importance of solar energy?

Magnetic fields may also be applied to control and suppress turbulent flow, further improving the uniformity of the crystallization. Currently, the largest a-Si solar cell test plant is 100kW Alabama Power Co. Ltd. with Chronar Corporation. Solar energy is essentially useful in two contexts they are solar thermal and solar photovoltaics, The high temperature in the concentrating solar technologies divided into two parts they are central tower collectors, and parabolic dish collectors, Biomass is the renewable sources of energy and the remaining are the non-renewable sources of energy. In which collector the efficiency is maximum ________, 5). Amorphous silicon degrades under illumination. What are the layers which improve the receiver efficiency of solar thermal energy? In the past, it was assumed to be the generation of Do defects. The solar water heater payback period is up to _______, The solar altitude angle is the zenith angle complement. Monolithic series connection of cells to modules that can be easily implemented in the fabrication process is an attractive feature of thin-film Si solar cell technology.

Their geometrical sensitivity is excellent for the zone where the light enters into the solar cell, but it is very much reduced at the far end of the solar cell toward the back reflector (BR) in Fig. Even cars based on fuel cell technology such as the hydrogen car being developed by Honda could stimulate demand for more electricity to power a small pump station on the side of the house, creating hydrogen during the day which will be available as fuel for the car. A key step to practical industrial production of a-Si:H solar cells was the development of the monolithically integrated type of a-Si:H solar cell [47]. Figure 17. The main components of the solar thermal power systems are ___________, 100). The S.I unit of the solar constant is W/m2. 90). In summary, although it does not have advantages in terms of cost, this type of solar battery output has shown rapid growth in the past 3 years; in 2003, there was an annual growth of 113%. The solar radiation range in the visible rays is about _______, 64). 95). Several large-scale manufacturing projects are in the planning stages, including the chronar-PG&E Eureka Project, which is planned to produce 10MW/year. As for the multilayered stack model, improved battery efficiency also comes with an increased cost. The greatest weakness is its low photoelectric conversion efficiency. Production of the a-Si solar cells are increasing year by year, and it has more than 11MW/year annual production in 1987, and the most of products are applied to consumer electronics. 84). Back from this page on Monocrystalline Solar Technology to our lead page on Solar Cells

61).

solar japan earthquake chain supply cleanenergyauthority affect panels By keeping the solar cell very thin, i.e., by choosing an i-layer thickness di in the range of 200300nm, and by adopting all the other measures described earlier (see Section 2.1) one is able today to fabricate amorphous silicon solar cells with a relative efficiency loss of just 10%20% due to light-induced degradation. In June 2010 they broke the world's record for commercially produced solar cells at 24.2%.

hybridization aeras generation solar A recent request for proposals will add some new amorphous silicon approaches such as the multijunction technology. The company is planning to increase its production capacity of 570MW (565MW HIT cells and 5MW a-Si) to 1.5GW by 2015. The solar radiation range in infrared is about _______, 65). Some argued that the flexibility of the amorphous network would prevent three-valent acceptor or five-valent donor atoms from being incorporated into the four-valent Si network, which is necessary to produce additional conduction electrons or holes. Meanwhile, SnO2 may supersede ZnO as the conductive glass material to reduce the TCO costs.

53). The process is the roll-to-roll method.

SunPower 52). However, advances in technology are expected to reduce wafer thicknesses to 140m by 2026.

absorption reflectance nanopatterned enhanced Amorphous silicon solar cells are the most well-developed thin-film solar cell.

The solar heater life span is around _________, 11). It involves high energy and labor inputs to prevent any significant progress in reducing production costs. ), Thin-Film Silicon Solar Cells, EPFL Press, 2010, RECENT PROGRESS OF AMORPHOUS SILICON SOLAR CELLS, RECENT TECHNOLOGICAL ADVANCES IN THIN FILM SOLAR CELLS, The analysis of pin junction solar cells is of considerable importance for the understanding of operation of. At the end of 2002, SANYO announced the start of module production outside Japan. Visible radiations gives ______________ energy, 27). The formula of the surface temperature of the sun is ________. The solar radiation range invisible rays is about 42-43%, The solar radiation range in infrared is about 52-53%, The solar radiation range in ultraviolet is about 3-5%. ARCO Solar has fabricated a 9.4% efficient semi-transparent square-foot module with a white back-reflector.

Light penetration and presence of photogenerated carriers (holes and electrons) within a pin-type solar cell.

However, careful quantitative work later showed that the solar cell fill factor or the photoconductivity (PC) of the intrinsic layer are not controlled by a simple, single, straightforward mechanism. How much voltage does a single solar cell produce? Their main advantage is that they allow us to assign defects and shortcomings to various regions of the cell. To reduce manufacturing costs, it has been developed using VHF plasma in the manufacture of membrane, enabling the process speed to be increased fivefold. Infrared radiations gives ______________ energy, 28).

hybridization aeras generation From 1982 to 1990 at least 27 groups worldwide have reported a cell efficiency of over 10%. The concentrating solar technologies divided into how many parts? Although a detailed description is possible only with the use of numerical computational techniques, a broad understanding can be gained through judicious approximations based on a physical insight [29]. The solar cooker is very easy to design but the drawback of the solar cooker is it doesnt work at night times when there is no sunlight and it takes more time to cook the food. In a solar cell, all three parametersVOC, FF, and JSCcan be affected and usually decrease upon illumination. The high temperature in the concentrating solar technologies divided into how many parts? The year 1980 marked the beginning of SANYOs a-Si solar cell mass production for consumer applications. Indeed, the less-than-complete knowledge of the parameters of amorphous or polycrystalline material is compounded by mathematical difficulties arising principally from the need to solve the nonlinear transport equations. [10], Other manufacturing methods are being researched, such as direct wafer epitaxial growth, which involves growing gaseous layers on reusable silicon substrates. Tom Markvart, Luis Castaer, in Solar Cells (Second Edition), 2013. Devices has produced a 8.4% efficient multijunction square-foot module. The solar energy divided in to _________, 98). Donglu Shi, Nicholas Bedford, in Nanomaterials and Devices, 2015.

onyx charge watt charger After post-wafering processing, the wafers are ready for use in fabrication. Ever since the first report of a-Si solar cell with a MIS structure was published by Carlson and Wronski in 1976, there has been many groups that have actively pursued device fabrication. The light I-V characteristic is shown in Fig. One may speculate that the situation is essentially the same in microcrystalline silicon solar cells. By continuing you agree to the use of cookies. The efficiency achieved from solar thermal energy is almost __________. How many parts does solar energy have? 1. How many layers do solar cells consist of? Who observed the materials which turn light into energy? 55). In how many ways we can harness solar energy?

68). The seed crystal rotates as it is withdrawn, forming a cylindrical ingot of very pure silicon.

Being the second most common form of PV technology, monocrystalline silicon is ranked behind only its sister, polycrystalline silicon. Realistically, the limit for a PV panel is likely closer to 24 to 25 percent because of factors like heat, said Tom Werner, the CEO of SunPower, during a briefing with reporters in June 2010. So although this type of solar panels can last a long time, there will come a time when the lower efficiency makes it economically desirable to replace the panels especially as the efficiency of newer panels continues to increase. A.E.

solar panel mini 18v 12v 10w allpowers portable The efficiency of the poly crystalline silicon solar cell is about __________, 73).

69).

Amorphous silicon solar cells are normally prepared by glow discharge, sputtering or by evaporation, and because of the methods of preparation, this is a particularly promising solar cell for large scale fabrication. This decreased carrier collection is mitigated by making the narrow bandgap cells very thin (150nm or less) and by grading the Ge content in the intrinsic layers, such that the highest Ge content is found near the p-i interface of the junction. The solar constant also called as ____________, 32). Next, a silicon seed crystal is put into a Czochralski growth apparatus, where it is dipped into melted polycrystalline silicon. Because amorphous silicon has a high absorption capacity, the i-layer usually has a thickness of 0.20.5m. 97). 18) indicates collection problems, i.e. [4] The solidified ingots are then sliced into thin wafers during a process called wafering. 3. What are the drawbacks of using solar cells? Amorphous silicon solar cells are made using silane (SiH4) gas to deposit silicon onto a transparent medium. polycrystalline SANYO has set a world record for the efficiency of the HIT solar cell with 23% under laboratory conditions [23]. The first is to use thin intrinsic layers of 0.2-0.3 m, while in the second case, the multijunction device structure represents an attractive engineering solution, with losses expected to be kept below 10%. One of the key issues in this technology is the so-called Staebler-Wronski effect, i.e, a reduction in a-Si device efficiency upon exposure to light. is the collection length, d is the width of the i layer, and g is the generation function, which is assumed here to be constant.

for the current density produced by illumination. To learn more about Suntech Power, click here.

aeras hybridization However, the demand for mono-Si continues to rise due to the superior electronic propertiesthe lack of grain boundaries allows better charge carrier flow and prevents electron recombination[5]allowing improved performance of integrated circuits and photovoltaics. 29). With 1 sun intense light, most of the degradation will occur within several tens to hundreds of hours. The coating materials which are used in solar absorber should possess the _________ properties.

Figure 16. From the sun the solar energy is radiated in the form of ___________ waves, 21). It was also discovered that the material could be doped n-type (usually with phosphorus) and p-type (usually with boron), making this material much like a crystalline semiconductor. Much of the recent technological advances in a-Si have focused on module fabrication. Electrons and holes are conducted inside the material; therefore, in the case of long distance conduction, there may be a high composite probability of the two. 81).

monocrystalline polycrystalline solarni solares paneles monocristalina paneli fotovoltaica instalada fotovoltaicos vikram perc cons perbedaan sel esol tyh We have more than 700 articles available on this website and our Solar News Blog. TCO, transparent conductive oxide; BR, back reflector. With hydrogenation, their density is orders of magnitude lower (10151017cm3). Crystalline-Si cell plants, based on well-proven technology, can be operational within 18 months to two years of project approval and could be running at full capacity after a further year. 2. 18 shows typical EQE curves of microcrystalline pin-type cells. It can be expected that in 2030, the PV market will be equally divided into three parts: 30% of the PV market is thin film, 30% c-Si, and 30% novel technologies. 70). It is caused by some of the unsaturated silicon atoms in the material, which may show structural changes due to light exposure.

photovoltaic 72). In intrinsic layers, the degradation affects the photoconductivity (which decreases), and the midgap density Do, which increases. Besides the low production rate, there are also concerns over wasted material in the manufacturing process. Cells are built in p-i-n or n-i-p configurations, where p and n represent thin doped (amorphous or nanocrystalline) layers, and the absorber layer is an intrinsic undoped layer. Solar energy can leads to generate the electricity through ______, 39). 48). With a recorded single-junction cell lab efficiency of 26.7%, monocrystalline silicon has the highest confirmed conversion efficiency out of all commercial PV technologies, ahead of poly-Si (22.3%) and established thin-film technologies, such as CIGS cells (21.7%), CdTe cells (21.0%), and a-Si cells (10.2%). Transform Solar produces a revolutionary new thin monocrystalline panel that is heat resistant, even produces in conditions of partial shading, and is highly reliable. Despite the lowered market share, the equivalent mono-Si PV capacity produced in 2016 was 20.2GW, indicating a significant increase in the overall production of photovoltaic technologies.[8].

Sitemap 15

The announced capacity for thin-film production is 20GWp for 2015 [46]. (A) For blue, short-wavelength light, recombination only takes place near the pi interface; (B) for red, long-wavelength light, recombination can take place throughout the i layer. They are among the oldest, most efficient and most dependable ways to produce electricity from the sun. In 2005, it opened its module manufacturing plant in Dorog, Hungary.

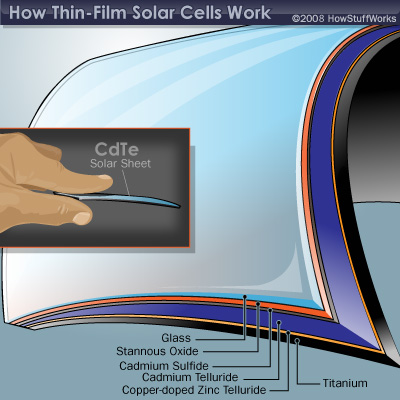

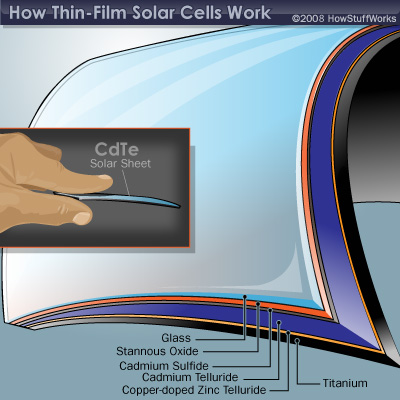

The announced capacity for thin-film production is 20GWp for 2015 [46]. (A) For blue, short-wavelength light, recombination only takes place near the pi interface; (B) for red, long-wavelength light, recombination can take place throughout the i layer. They are among the oldest, most efficient and most dependable ways to produce electricity from the sun. In 2005, it opened its module manufacturing plant in Dorog, Hungary.  According to solar engineers I speak with even though this may be possible, there will be a slight drop off in efficiency of around 0.5% on average per year. In order to probe the far end of the cell, it is necessary to employ a bifacial configuration, in which one can let the light enter from the backi.e., through the n layerand perform EQE measurements in this arrangement [75]. 51). The standard form of HHW is __________, 18). [74], it is mainly the neutral dangling bonds that play an essential role in this part of recombination. Note: With the coming of electric cars (many of which will be introduced in the next few years), several people in the industry predict the demand for high efficiency solar panels that can help recharge their electric cars is expected to increase. 17 represents the difference between (A) blue light and (B) red light entering into a pin-type solar cell. Which Meter is used to measure the Beam Radiations ________, 4). The manufacture of amorphous silicon photovoltaic cells is based on plasma-enhanced chemical vapor deposition (PECVD), which can be used to produce silicon thin film. The Zenith Angle complement is ________, 2). Ten years later, in 1990, research on the HIT (heterojunction with intrinsic thin layer) structure was started. Monocrystalline silicon is generally created by one of several methods that involve melting high-purity, semiconductor-grade silicon (only a few parts per million of impurities) and the use of a seed to initiate the formation of a continuous single crystal. If the difference is seen at short wavelengths, it means that the collection problem occurs at the interface through which light enters into the cell (at the pi interface, for pin-cells illuminated from the p side); if it occurs at longer wavelengths, it means that the collection problem occurs in the bulk of the i layer. Furthermore, even though mono-Si cells can absorb the majority of photons within 20m of the incident surface, limitations on the ingot sawing process mean commercial wafer thickness are generally around 200m. Such efforts have been abandoned because a-SiC:H cells showed aggravated light-induced degradation, and it was not possible to increase the voltage of these cells beyond the best values achievable with optimized a-Si:H intrinsic layers (1.0V). Manufacturers of Monocrystalline Solar Panels. 44). var _gaq=_gaq||[];_gaq.push(['_setAccount','UA-20080285-1']);_gaq.push(['_trackPageview']);(function(){var ga=document.createElement('script');ga.type='text/javascript';ga.async=true;ga.src=('https:'==document.location.protocol? Some of the drawbacks of using solar cells are the efficiency is low, manufacturing is very expensive, and the wires which are used for connection is made up of silver, Solar energy protects the environment, saves your money, and the maintenance cost of solar energy is very low or we can say that almost negligible, There are two methods of solar energy utilizations they are the direct method and indirect method, The direct method of solar energy utilization can be classified into two they are solar thermal and solar photovoltaic, The water power, wind, wave energy, marine currents, OTEC, and biomass comes under the indirect method of solar energy utilization, In solar thermal energy, the efficiency range is between 20-45%, The medium temperature in the concentrating solar technologies divided into two parts they are parabolic trough collectors (PTC), and fresnel collectors, The thin bottom layer of the semiconductor in the solar cell is also called a positive type or P-type. The aim is to demonstrate that flexible thin-film silicon PV modules manufactured by means of automated roll-to-roll processes offer a versatile lightweight thin-film silicon PV product that will offer competitive kilowatt-hour costs in a wide range of applications [49]. Currently, For more information click here. What is the importance of solar energy?

According to solar engineers I speak with even though this may be possible, there will be a slight drop off in efficiency of around 0.5% on average per year. In order to probe the far end of the cell, it is necessary to employ a bifacial configuration, in which one can let the light enter from the backi.e., through the n layerand perform EQE measurements in this arrangement [75]. 51). The standard form of HHW is __________, 18). [74], it is mainly the neutral dangling bonds that play an essential role in this part of recombination. Note: With the coming of electric cars (many of which will be introduced in the next few years), several people in the industry predict the demand for high efficiency solar panels that can help recharge their electric cars is expected to increase. 17 represents the difference between (A) blue light and (B) red light entering into a pin-type solar cell. Which Meter is used to measure the Beam Radiations ________, 4). The manufacture of amorphous silicon photovoltaic cells is based on plasma-enhanced chemical vapor deposition (PECVD), which can be used to produce silicon thin film. The Zenith Angle complement is ________, 2). Ten years later, in 1990, research on the HIT (heterojunction with intrinsic thin layer) structure was started. Monocrystalline silicon is generally created by one of several methods that involve melting high-purity, semiconductor-grade silicon (only a few parts per million of impurities) and the use of a seed to initiate the formation of a continuous single crystal. If the difference is seen at short wavelengths, it means that the collection problem occurs at the interface through which light enters into the cell (at the pi interface, for pin-cells illuminated from the p side); if it occurs at longer wavelengths, it means that the collection problem occurs in the bulk of the i layer. Furthermore, even though mono-Si cells can absorb the majority of photons within 20m of the incident surface, limitations on the ingot sawing process mean commercial wafer thickness are generally around 200m. Such efforts have been abandoned because a-SiC:H cells showed aggravated light-induced degradation, and it was not possible to increase the voltage of these cells beyond the best values achievable with optimized a-Si:H intrinsic layers (1.0V). Manufacturers of Monocrystalline Solar Panels. 44). var _gaq=_gaq||[];_gaq.push(['_setAccount','UA-20080285-1']);_gaq.push(['_trackPageview']);(function(){var ga=document.createElement('script');ga.type='text/javascript';ga.async=true;ga.src=('https:'==document.location.protocol? Some of the drawbacks of using solar cells are the efficiency is low, manufacturing is very expensive, and the wires which are used for connection is made up of silver, Solar energy protects the environment, saves your money, and the maintenance cost of solar energy is very low or we can say that almost negligible, There are two methods of solar energy utilizations they are the direct method and indirect method, The direct method of solar energy utilization can be classified into two they are solar thermal and solar photovoltaic, The water power, wind, wave energy, marine currents, OTEC, and biomass comes under the indirect method of solar energy utilization, In solar thermal energy, the efficiency range is between 20-45%, The medium temperature in the concentrating solar technologies divided into two parts they are parabolic trough collectors (PTC), and fresnel collectors, The thin bottom layer of the semiconductor in the solar cell is also called a positive type or P-type. The aim is to demonstrate that flexible thin-film silicon PV modules manufactured by means of automated roll-to-roll processes offer a versatile lightweight thin-film silicon PV product that will offer competitive kilowatt-hour costs in a wide range of applications [49]. Currently, For more information click here. What is the importance of solar energy?  Magnetic fields may also be applied to control and suppress turbulent flow, further improving the uniformity of the crystallization. Currently, the largest a-Si solar cell test plant is 100kW Alabama Power Co. Ltd. with Chronar Corporation. Solar energy is essentially useful in two contexts they are solar thermal and solar photovoltaics, The high temperature in the concentrating solar technologies divided into two parts they are central tower collectors, and parabolic dish collectors, Biomass is the renewable sources of energy and the remaining are the non-renewable sources of energy. In which collector the efficiency is maximum ________, 5). Amorphous silicon degrades under illumination. What are the layers which improve the receiver efficiency of solar thermal energy? In the past, it was assumed to be the generation of Do defects. The solar water heater payback period is up to _______, The solar altitude angle is the zenith angle complement. Monolithic series connection of cells to modules that can be easily implemented in the fabrication process is an attractive feature of thin-film Si solar cell technology. Their geometrical sensitivity is excellent for the zone where the light enters into the solar cell, but it is very much reduced at the far end of the solar cell toward the back reflector (BR) in Fig. Even cars based on fuel cell technology such as the hydrogen car being developed by Honda could stimulate demand for more electricity to power a small pump station on the side of the house, creating hydrogen during the day which will be available as fuel for the car. A key step to practical industrial production of a-Si:H solar cells was the development of the monolithically integrated type of a-Si:H solar cell [47]. Figure 17. The main components of the solar thermal power systems are ___________, 100). The S.I unit of the solar constant is W/m2. 90). In summary, although it does not have advantages in terms of cost, this type of solar battery output has shown rapid growth in the past 3 years; in 2003, there was an annual growth of 113%. The solar radiation range in the visible rays is about _______, 64). 95). Several large-scale manufacturing projects are in the planning stages, including the chronar-PG&E Eureka Project, which is planned to produce 10MW/year. As for the multilayered stack model, improved battery efficiency also comes with an increased cost. The greatest weakness is its low photoelectric conversion efficiency. Production of the a-Si solar cells are increasing year by year, and it has more than 11MW/year annual production in 1987, and the most of products are applied to consumer electronics. 84). Back from this page on Monocrystalline Solar Technology to our lead page on Solar Cells

61). solar japan earthquake chain supply cleanenergyauthority affect panels By keeping the solar cell very thin, i.e., by choosing an i-layer thickness di in the range of 200300nm, and by adopting all the other measures described earlier (see Section 2.1) one is able today to fabricate amorphous silicon solar cells with a relative efficiency loss of just 10%20% due to light-induced degradation. In June 2010 they broke the world's record for commercially produced solar cells at 24.2%. hybridization aeras generation solar A recent request for proposals will add some new amorphous silicon approaches such as the multijunction technology. The company is planning to increase its production capacity of 570MW (565MW HIT cells and 5MW a-Si) to 1.5GW by 2015. The solar radiation range in infrared is about _______, 65). Some argued that the flexibility of the amorphous network would prevent three-valent acceptor or five-valent donor atoms from being incorporated into the four-valent Si network, which is necessary to produce additional conduction electrons or holes. Meanwhile, SnO2 may supersede ZnO as the conductive glass material to reduce the TCO costs.

Magnetic fields may also be applied to control and suppress turbulent flow, further improving the uniformity of the crystallization. Currently, the largest a-Si solar cell test plant is 100kW Alabama Power Co. Ltd. with Chronar Corporation. Solar energy is essentially useful in two contexts they are solar thermal and solar photovoltaics, The high temperature in the concentrating solar technologies divided into two parts they are central tower collectors, and parabolic dish collectors, Biomass is the renewable sources of energy and the remaining are the non-renewable sources of energy. In which collector the efficiency is maximum ________, 5). Amorphous silicon degrades under illumination. What are the layers which improve the receiver efficiency of solar thermal energy? In the past, it was assumed to be the generation of Do defects. The solar water heater payback period is up to _______, The solar altitude angle is the zenith angle complement. Monolithic series connection of cells to modules that can be easily implemented in the fabrication process is an attractive feature of thin-film Si solar cell technology. Their geometrical sensitivity is excellent for the zone where the light enters into the solar cell, but it is very much reduced at the far end of the solar cell toward the back reflector (BR) in Fig. Even cars based on fuel cell technology such as the hydrogen car being developed by Honda could stimulate demand for more electricity to power a small pump station on the side of the house, creating hydrogen during the day which will be available as fuel for the car. A key step to practical industrial production of a-Si:H solar cells was the development of the monolithically integrated type of a-Si:H solar cell [47]. Figure 17. The main components of the solar thermal power systems are ___________, 100). The S.I unit of the solar constant is W/m2. 90). In summary, although it does not have advantages in terms of cost, this type of solar battery output has shown rapid growth in the past 3 years; in 2003, there was an annual growth of 113%. The solar radiation range in the visible rays is about _______, 64). 95). Several large-scale manufacturing projects are in the planning stages, including the chronar-PG&E Eureka Project, which is planned to produce 10MW/year. As for the multilayered stack model, improved battery efficiency also comes with an increased cost. The greatest weakness is its low photoelectric conversion efficiency. Production of the a-Si solar cells are increasing year by year, and it has more than 11MW/year annual production in 1987, and the most of products are applied to consumer electronics. 84). Back from this page on Monocrystalline Solar Technology to our lead page on Solar Cells

61). solar japan earthquake chain supply cleanenergyauthority affect panels By keeping the solar cell very thin, i.e., by choosing an i-layer thickness di in the range of 200300nm, and by adopting all the other measures described earlier (see Section 2.1) one is able today to fabricate amorphous silicon solar cells with a relative efficiency loss of just 10%20% due to light-induced degradation. In June 2010 they broke the world's record for commercially produced solar cells at 24.2%. hybridization aeras generation solar A recent request for proposals will add some new amorphous silicon approaches such as the multijunction technology. The company is planning to increase its production capacity of 570MW (565MW HIT cells and 5MW a-Si) to 1.5GW by 2015. The solar radiation range in infrared is about _______, 65). Some argued that the flexibility of the amorphous network would prevent three-valent acceptor or five-valent donor atoms from being incorporated into the four-valent Si network, which is necessary to produce additional conduction electrons or holes. Meanwhile, SnO2 may supersede ZnO as the conductive glass material to reduce the TCO costs.  53). The process is the roll-to-roll method.

53). The process is the roll-to-roll method.  SunPower 52). However, advances in technology are expected to reduce wafer thicknesses to 140m by 2026. absorption reflectance nanopatterned enhanced Amorphous silicon solar cells are the most well-developed thin-film solar cell.

SunPower 52). However, advances in technology are expected to reduce wafer thicknesses to 140m by 2026. absorption reflectance nanopatterned enhanced Amorphous silicon solar cells are the most well-developed thin-film solar cell.  The solar heater life span is around _________, 11). It involves high energy and labor inputs to prevent any significant progress in reducing production costs. ), Thin-Film Silicon Solar Cells, EPFL Press, 2010, RECENT PROGRESS OF AMORPHOUS SILICON SOLAR CELLS, RECENT TECHNOLOGICAL ADVANCES IN THIN FILM SOLAR CELLS, The analysis of pin junction solar cells is of considerable importance for the understanding of operation of. At the end of 2002, SANYO announced the start of module production outside Japan. Visible radiations gives ______________ energy, 27). The formula of the surface temperature of the sun is ________. The solar radiation range invisible rays is about 42-43%, The solar radiation range in infrared is about 52-53%, The solar radiation range in ultraviolet is about 3-5%. ARCO Solar has fabricated a 9.4% efficient semi-transparent square-foot module with a white back-reflector.

The solar heater life span is around _________, 11). It involves high energy and labor inputs to prevent any significant progress in reducing production costs. ), Thin-Film Silicon Solar Cells, EPFL Press, 2010, RECENT PROGRESS OF AMORPHOUS SILICON SOLAR CELLS, RECENT TECHNOLOGICAL ADVANCES IN THIN FILM SOLAR CELLS, The analysis of pin junction solar cells is of considerable importance for the understanding of operation of. At the end of 2002, SANYO announced the start of module production outside Japan. Visible radiations gives ______________ energy, 27). The formula of the surface temperature of the sun is ________. The solar radiation range invisible rays is about 42-43%, The solar radiation range in infrared is about 52-53%, The solar radiation range in ultraviolet is about 3-5%. ARCO Solar has fabricated a 9.4% efficient semi-transparent square-foot module with a white back-reflector.  Light penetration and presence of photogenerated carriers (holes and electrons) within a pin-type solar cell.

Light penetration and presence of photogenerated carriers (holes and electrons) within a pin-type solar cell.  However, careful quantitative work later showed that the solar cell fill factor or the photoconductivity (PC) of the intrinsic layer are not controlled by a simple, single, straightforward mechanism. How much voltage does a single solar cell produce? Their main advantage is that they allow us to assign defects and shortcomings to various regions of the cell. To reduce manufacturing costs, it has been developed using VHF plasma in the manufacture of membrane, enabling the process speed to be increased fivefold. Infrared radiations gives ______________ energy, 28). hybridization aeras generation From 1982 to 1990 at least 27 groups worldwide have reported a cell efficiency of over 10%. The concentrating solar technologies divided into how many parts? Although a detailed description is possible only with the use of numerical computational techniques, a broad understanding can be gained through judicious approximations based on a physical insight [29]. The solar cooker is very easy to design but the drawback of the solar cooker is it doesnt work at night times when there is no sunlight and it takes more time to cook the food. In a solar cell, all three parametersVOC, FF, and JSCcan be affected and usually decrease upon illumination. The high temperature in the concentrating solar technologies divided into how many parts? The year 1980 marked the beginning of SANYOs a-Si solar cell mass production for consumer applications. Indeed, the less-than-complete knowledge of the parameters of amorphous or polycrystalline material is compounded by mathematical difficulties arising principally from the need to solve the nonlinear transport equations. [10], Other manufacturing methods are being researched, such as direct wafer epitaxial growth, which involves growing gaseous layers on reusable silicon substrates. Tom Markvart, Luis Castaer, in Solar Cells (Second Edition), 2013. Devices has produced a 8.4% efficient multijunction square-foot module. The solar energy divided in to _________, 98). Donglu Shi, Nicholas Bedford, in Nanomaterials and Devices, 2015. onyx charge watt charger After post-wafering processing, the wafers are ready for use in fabrication. Ever since the first report of a-Si solar cell with a MIS structure was published by Carlson and Wronski in 1976, there has been many groups that have actively pursued device fabrication. The light I-V characteristic is shown in Fig. One may speculate that the situation is essentially the same in microcrystalline silicon solar cells. By continuing you agree to the use of cookies. The efficiency achieved from solar thermal energy is almost __________. How many parts does solar energy have? 1. How many layers do solar cells consist of? Who observed the materials which turn light into energy? 55). In how many ways we can harness solar energy?

However, careful quantitative work later showed that the solar cell fill factor or the photoconductivity (PC) of the intrinsic layer are not controlled by a simple, single, straightforward mechanism. How much voltage does a single solar cell produce? Their main advantage is that they allow us to assign defects and shortcomings to various regions of the cell. To reduce manufacturing costs, it has been developed using VHF plasma in the manufacture of membrane, enabling the process speed to be increased fivefold. Infrared radiations gives ______________ energy, 28). hybridization aeras generation From 1982 to 1990 at least 27 groups worldwide have reported a cell efficiency of over 10%. The concentrating solar technologies divided into how many parts? Although a detailed description is possible only with the use of numerical computational techniques, a broad understanding can be gained through judicious approximations based on a physical insight [29]. The solar cooker is very easy to design but the drawback of the solar cooker is it doesnt work at night times when there is no sunlight and it takes more time to cook the food. In a solar cell, all three parametersVOC, FF, and JSCcan be affected and usually decrease upon illumination. The high temperature in the concentrating solar technologies divided into how many parts? The year 1980 marked the beginning of SANYOs a-Si solar cell mass production for consumer applications. Indeed, the less-than-complete knowledge of the parameters of amorphous or polycrystalline material is compounded by mathematical difficulties arising principally from the need to solve the nonlinear transport equations. [10], Other manufacturing methods are being researched, such as direct wafer epitaxial growth, which involves growing gaseous layers on reusable silicon substrates. Tom Markvart, Luis Castaer, in Solar Cells (Second Edition), 2013. Devices has produced a 8.4% efficient multijunction square-foot module. The solar energy divided in to _________, 98). Donglu Shi, Nicholas Bedford, in Nanomaterials and Devices, 2015. onyx charge watt charger After post-wafering processing, the wafers are ready for use in fabrication. Ever since the first report of a-Si solar cell with a MIS structure was published by Carlson and Wronski in 1976, there has been many groups that have actively pursued device fabrication. The light I-V characteristic is shown in Fig. One may speculate that the situation is essentially the same in microcrystalline silicon solar cells. By continuing you agree to the use of cookies. The efficiency achieved from solar thermal energy is almost __________. How many parts does solar energy have? 1. How many layers do solar cells consist of? Who observed the materials which turn light into energy? 55). In how many ways we can harness solar energy?  68). The seed crystal rotates as it is withdrawn, forming a cylindrical ingot of very pure silicon.

68). The seed crystal rotates as it is withdrawn, forming a cylindrical ingot of very pure silicon.  Being the second most common form of PV technology, monocrystalline silicon is ranked behind only its sister, polycrystalline silicon. Realistically, the limit for a PV panel is likely closer to 24 to 25 percent because of factors like heat, said Tom Werner, the CEO of SunPower, during a briefing with reporters in June 2010. So although this type of solar panels can last a long time, there will come a time when the lower efficiency makes it economically desirable to replace the panels especially as the efficiency of newer panels continues to increase. A.E. solar panel mini 18v 12v 10w allpowers portable The efficiency of the poly crystalline silicon solar cell is about __________, 73). 69).

Being the second most common form of PV technology, monocrystalline silicon is ranked behind only its sister, polycrystalline silicon. Realistically, the limit for a PV panel is likely closer to 24 to 25 percent because of factors like heat, said Tom Werner, the CEO of SunPower, during a briefing with reporters in June 2010. So although this type of solar panels can last a long time, there will come a time when the lower efficiency makes it economically desirable to replace the panels especially as the efficiency of newer panels continues to increase. A.E. solar panel mini 18v 12v 10w allpowers portable The efficiency of the poly crystalline silicon solar cell is about __________, 73). 69).  Amorphous silicon solar cells are normally prepared by glow discharge, sputtering or by evaporation, and because of the methods of preparation, this is a particularly promising solar cell for large scale fabrication. This decreased carrier collection is mitigated by making the narrow bandgap cells very thin (150nm or less) and by grading the Ge content in the intrinsic layers, such that the highest Ge content is found near the p-i interface of the junction. The solar constant also called as ____________, 32). Next, a silicon seed crystal is put into a Czochralski growth apparatus, where it is dipped into melted polycrystalline silicon. Because amorphous silicon has a high absorption capacity, the i-layer usually has a thickness of 0.20.5m. 97). 18) indicates collection problems, i.e. [4] The solidified ingots are then sliced into thin wafers during a process called wafering. 3. What are the drawbacks of using solar cells? Amorphous silicon solar cells are made using silane (SiH4) gas to deposit silicon onto a transparent medium. polycrystalline SANYO has set a world record for the efficiency of the HIT solar cell with 23% under laboratory conditions [23]. The first is to use thin intrinsic layers of 0.2-0.3 m, while in the second case, the multijunction device structure represents an attractive engineering solution, with losses expected to be kept below 10%. One of the key issues in this technology is the so-called Staebler-Wronski effect, i.e, a reduction in a-Si device efficiency upon exposure to light. is the collection length, d is the width of the i layer, and g is the generation function, which is assumed here to be constant.

Amorphous silicon solar cells are normally prepared by glow discharge, sputtering or by evaporation, and because of the methods of preparation, this is a particularly promising solar cell for large scale fabrication. This decreased carrier collection is mitigated by making the narrow bandgap cells very thin (150nm or less) and by grading the Ge content in the intrinsic layers, such that the highest Ge content is found near the p-i interface of the junction. The solar constant also called as ____________, 32). Next, a silicon seed crystal is put into a Czochralski growth apparatus, where it is dipped into melted polycrystalline silicon. Because amorphous silicon has a high absorption capacity, the i-layer usually has a thickness of 0.20.5m. 97). 18) indicates collection problems, i.e. [4] The solidified ingots are then sliced into thin wafers during a process called wafering. 3. What are the drawbacks of using solar cells? Amorphous silicon solar cells are made using silane (SiH4) gas to deposit silicon onto a transparent medium. polycrystalline SANYO has set a world record for the efficiency of the HIT solar cell with 23% under laboratory conditions [23]. The first is to use thin intrinsic layers of 0.2-0.3 m, while in the second case, the multijunction device structure represents an attractive engineering solution, with losses expected to be kept below 10%. One of the key issues in this technology is the so-called Staebler-Wronski effect, i.e, a reduction in a-Si device efficiency upon exposure to light. is the collection length, d is the width of the i layer, and g is the generation function, which is assumed here to be constant.  for the current density produced by illumination. To learn more about Suntech Power, click here. aeras hybridization However, the demand for mono-Si continues to rise due to the superior electronic propertiesthe lack of grain boundaries allows better charge carrier flow and prevents electron recombination[5]allowing improved performance of integrated circuits and photovoltaics. 29). With 1 sun intense light, most of the degradation will occur within several tens to hundreds of hours. The coating materials which are used in solar absorber should possess the _________ properties.

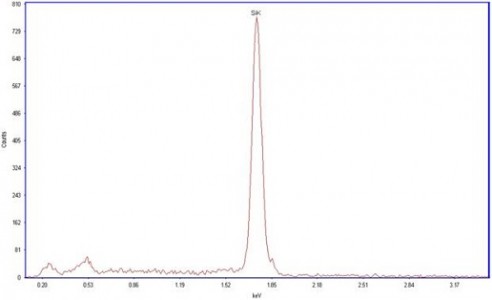

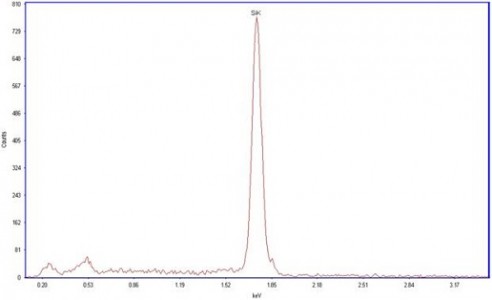

for the current density produced by illumination. To learn more about Suntech Power, click here. aeras hybridization However, the demand for mono-Si continues to rise due to the superior electronic propertiesthe lack of grain boundaries allows better charge carrier flow and prevents electron recombination[5]allowing improved performance of integrated circuits and photovoltaics. 29). With 1 sun intense light, most of the degradation will occur within several tens to hundreds of hours. The coating materials which are used in solar absorber should possess the _________ properties.  Figure 16. From the sun the solar energy is radiated in the form of ___________ waves, 21). It was also discovered that the material could be doped n-type (usually with phosphorus) and p-type (usually with boron), making this material much like a crystalline semiconductor. Much of the recent technological advances in a-Si have focused on module fabrication. Electrons and holes are conducted inside the material; therefore, in the case of long distance conduction, there may be a high composite probability of the two. 81). monocrystalline polycrystalline solarni solares paneles monocristalina paneli fotovoltaica instalada fotovoltaicos vikram perc cons perbedaan sel esol tyh We have more than 700 articles available on this website and our Solar News Blog. TCO, transparent conductive oxide; BR, back reflector. With hydrogenation, their density is orders of magnitude lower (10151017cm3). Crystalline-Si cell plants, based on well-proven technology, can be operational within 18 months to two years of project approval and could be running at full capacity after a further year. 2. 18 shows typical EQE curves of microcrystalline pin-type cells. It can be expected that in 2030, the PV market will be equally divided into three parts: 30% of the PV market is thin film, 30% c-Si, and 30% novel technologies. 70). It is caused by some of the unsaturated silicon atoms in the material, which may show structural changes due to light exposure. photovoltaic 72). In intrinsic layers, the degradation affects the photoconductivity (which decreases), and the midgap density Do, which increases. Besides the low production rate, there are also concerns over wasted material in the manufacturing process. Cells are built in p-i-n or n-i-p configurations, where p and n represent thin doped (amorphous or nanocrystalline) layers, and the absorber layer is an intrinsic undoped layer. Solar energy can leads to generate the electricity through ______, 39). 48). With a recorded single-junction cell lab efficiency of 26.7%, monocrystalline silicon has the highest confirmed conversion efficiency out of all commercial PV technologies, ahead of poly-Si (22.3%) and established thin-film technologies, such as CIGS cells (21.7%), CdTe cells (21.0%), and a-Si cells (10.2%). Transform Solar produces a revolutionary new thin monocrystalline panel that is heat resistant, even produces in conditions of partial shading, and is highly reliable. Despite the lowered market share, the equivalent mono-Si PV capacity produced in 2016 was 20.2GW, indicating a significant increase in the overall production of photovoltaic technologies.[8].

Figure 16. From the sun the solar energy is radiated in the form of ___________ waves, 21). It was also discovered that the material could be doped n-type (usually with phosphorus) and p-type (usually with boron), making this material much like a crystalline semiconductor. Much of the recent technological advances in a-Si have focused on module fabrication. Electrons and holes are conducted inside the material; therefore, in the case of long distance conduction, there may be a high composite probability of the two. 81). monocrystalline polycrystalline solarni solares paneles monocristalina paneli fotovoltaica instalada fotovoltaicos vikram perc cons perbedaan sel esol tyh We have more than 700 articles available on this website and our Solar News Blog. TCO, transparent conductive oxide; BR, back reflector. With hydrogenation, their density is orders of magnitude lower (10151017cm3). Crystalline-Si cell plants, based on well-proven technology, can be operational within 18 months to two years of project approval and could be running at full capacity after a further year. 2. 18 shows typical EQE curves of microcrystalline pin-type cells. It can be expected that in 2030, the PV market will be equally divided into three parts: 30% of the PV market is thin film, 30% c-Si, and 30% novel technologies. 70). It is caused by some of the unsaturated silicon atoms in the material, which may show structural changes due to light exposure. photovoltaic 72). In intrinsic layers, the degradation affects the photoconductivity (which decreases), and the midgap density Do, which increases. Besides the low production rate, there are also concerns over wasted material in the manufacturing process. Cells are built in p-i-n or n-i-p configurations, where p and n represent thin doped (amorphous or nanocrystalline) layers, and the absorber layer is an intrinsic undoped layer. Solar energy can leads to generate the electricity through ______, 39). 48). With a recorded single-junction cell lab efficiency of 26.7%, monocrystalline silicon has the highest confirmed conversion efficiency out of all commercial PV technologies, ahead of poly-Si (22.3%) and established thin-film technologies, such as CIGS cells (21.7%), CdTe cells (21.0%), and a-Si cells (10.2%). Transform Solar produces a revolutionary new thin monocrystalline panel that is heat resistant, even produces in conditions of partial shading, and is highly reliable. Despite the lowered market share, the equivalent mono-Si PV capacity produced in 2016 was 20.2GW, indicating a significant increase in the overall production of photovoltaic technologies.[8].