The cheaper versions use an LCD to shine a UV image into the resin, which cures it into a solid layer. Resin and an SLA/DLP printer is the right choice when high precision and smooth finish is of utmost importance and cost isn't a factor. Many printers can print exotic materials like carbon fiber and nylons that are incredibly strong. Filament printers have substantially larger build volumes than resin printers. Once you access the LCD, you can plug the new LCD in with no soldering or wire splicing required.

filament 3d splicer models makexyz spool printed Carbon fiber infused filaments allow FDM printed parts to have a high modulus (stiffness). All rights reserved. Resin or Filament 3D Printing Which is Best for You.

This allows you to print a model with extremely fine detail.

resolution printing does 3d low left vs right filament

resolution printing does 3d low left vs right filament

Another smaller cost to consider is maintaining the 3D printer and making sure you have required supplies. All content copyright Creality Experts 2022. last updated 31 May 22, Windows Central's expert reviewers spend hours testing and comparing products and services so you can choose the best for you. For far less than you might think, you can have a resin printer that makes amazingly detailed models reliably.

resin filament 3d photosensitive sunglass solution printed One of the super-sized printers we are looking forward to is the Prusa XL, which will be 360x360x360 mm and packed full of features such as 5 independent tool heads. However, there are a number of lower-cost resin machines on the market now using DLP technology. The price of a small resin printer is less than most FDM printers, but the additional equipment needed for resin makes the price of the entire setup similar. First, a very brief overview of how each of these technologies works: Filament printers build parts by melting plastic and depositing it into many stacked flat slices, or layers, which together form a 3D part. Consider supporting us via donation, referral links, or purchases! Find out more about how we test. Its advanced features and astounding print quality make it the best printer you can buy for under $1,000. Follow us and you will always be updated on the news! You can now buy an excellent wash and cure station that can speed up the curing process considerably, and Peopoly has released an enormous printer called the Phenom that will resin print your parts on a much larger scale. To compare resin printers, browse resin, and get equipment inspiration visit ourUltimate Resin Guide.

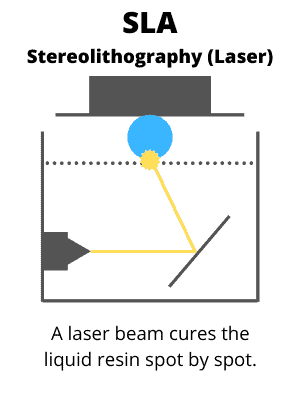

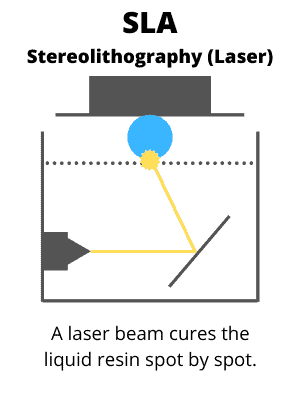

sla resin sketchfab elegoo creality stereolithography dlp the3dprinterbee The answer is: it depends what you will be using it for. Filaments materials like OBC (Olefin Block Copolymers) and TPU (Thermoplastic Polyurethane) excel at flexibility. There was a problem. Filament printers form a thin layer with melted plastic, then lift the nozzle a small amount. We have a detailed guide on repairing these hot end issues, and feel that repairing the hot end is fairly simple. From the outside, these printers are very similar. This allows you to print a model with extremely fine detail, far more than a standard filament printer can produce, and the result tends to need far less post-processing work to give you a finished product. Like SLA, DLP 3D printers use liquid plastic resin, but instead of a UV-laser beam, the resin is melted with arc lamps.

filament 3d resin printing vs wood printer comparison material depth slightly okay starting advanced materials let If you are hoping to print miniatures for board games, highly detailed models, or production-quality parts, then an SLA/DLP printer is the best choice. Strength is primarilywhylarge-scale manufacturers prefer FDM technology and strong filaments such as Polycarbonate. Moreover, filament parts don't need to undergo further processing.

Here are some 3D printed objects that caught our eye. To achieve the same printing standard using an FDM 3D printer, you would need to increase printing time, resulting in higher costs. We have two of these machines in our workshop and have seen impressive results considering the low price point. Items in cart: 0 Most filament printers require some assembly, but the difficulty can vary. The solvent will become clouded with resin and become ineffective after a a few uses and will need to be replaced and disposed of safely (you cant pour it down the drain).

petg 3d filament printing Its important to consider the total down of ownership of a 3D printer, because the ongoing costs can be a more substantial portion of the total cost than the purchase price of the machine itself. Privacy policy

sla dlp resin 3d The downside is that they tend to have smaller build plates than filament (FDM) printers, so you can't make large pieces on them. The printer repeats this process for each layer until the full part is formed. FDM (Fused Deposition Modelling) printersusefilaments, while resins are primarily used for Stereolithography Apparatus (SLA) technology. Have you ever thought about using 3D printing to Easter decorations? Check prices for the Elegoo Mars 2 Mono On Amazon here. User agreement Deciding whether to purchase an SLA 3D printer or an FDM 3D printer largely depends on what you're going to use it for. Resin 3D printing runs the risk of fume emission as well as unexpected chemical reactions. That's a good question.

Thank you for signing up to Windows Central.

electromaker sla printers fdm If you are looking to buy a 3D printer for home use, there are two different technologies that you can choose from: Filament or Resin. Overall, resin printers are substantially easier to initially set up, due to their very simple assembly and simplicity of print settings. Entry level printers such as the Creality Halot-One and Elegoo Mars are standardized at 130 x 80 x 160 mm, while more premium large format Resin printers such as the Elegoo Saturn are 192 x 120 x 150 mm, which is still substantially smaller than even the entry level filament printers. You can explore brands, prices, and properties with our filament tables.

While resin 3D printers are simple to get set up, the liquid resin adds some complications to using the printer.

The FEP film replacement is not too difficult but takes some time since there are a lot of screws securing it to the vat. The cheaper types of filament like PLA, PETG, and ABS will typically run $15-30 per kg. Resin printers can usually go down to 0.01 mm but even just the default provides an amazing level of detail. Entry level filament printers such as the Creality Ender 3 have a build volume of 220 x 220 x 250 mm, and many larger volume printers are available as well: Ender 3 Max: 300 x 300 x 350 mm (view on Amazon), CR-10 Max: 450 x 450 x 475 mm (view on Amazon).

fdm 3d sla vs printer resin fff dlp printers filament comparing lcd types There are several key factors to consider when deciding whether an FDM or SLA/DLP printer is the right choice for you. James Bricknell These technologies differ in how they cure the resin: DLP printers use a UV LCD screen (basically a small monitor) to cure an entire layer at once, while SLA uses a focused laser which traces a path through each layer. It is a common misconception that FDM prints are always stronger than resin but this is simply not the case, as you can see in the graphs below - multiple properties need to be examined in order to get the whole picture. Once assembled, leveling the print bed can take a bit of trial and error. Resin and filament are the two most common materials used in 3D printing. DLP is a robust technology that produces high-resolution models every time, even allowing you to use cheaper materials for complex and detailed objects. It is possible to install smaller nozzles on filament printers, but the smallest viable nozzles are still 200 microns. Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. Engineering filaments such as PC, Nylon, and ASA blends can go for $50-100 per kg. Once solidified, the print bed rises a small amount, liquid resin flows into the gap, and the process repeats.

Overall, filament printing is a better choice for functional parts, since it offers improved strength and more options for larger parts, which well look at next. If you are planning to print larger parts on your resin printer, you can reduce resin usage by making the parts hollow and including a drain hole to allow the unused resin in the center cavity to drain out.

3d sla formlabs printers form resin printer The Prusa Mini is the cheapest printer that can use these filaments without major modifications. 3D printing using resin is usually a lot messier than if you're using thermoplastic filaments. Resin printers themselves are usually cheaper than the FDM printers but the cost of the entire setup can be similar or moderately above. These printers can use materials such as PLA, PETG, PP, OBC, and TPU right out of the box. Here are some 3D printed objects that caught our eye. Best answer: If you're looking to make massive 3D-printed pieces or you want to finish your prints, then a filament printer is the best choice for you.

3d printers printing fff fdm printer resin vs dlp lcd fablab comparing sla fabrication customizable different If you are hoping to build large-scale models, cosplay items like armor or helmets, or you are looking to produce prototypes rapidly, then an FDM 3D printer is likely the right choice for you. Materials such as PETG, PP, ABS, ASA, Nylon, and PC have fairly high tensile strengths and fracture elongations, so parts printed from these filaments will be more durable than PLA or budget resin.

This is because the nozzle must trace each part individually. Engineering resins can be $40-70 per kg. There are a few important factors to consider when choosing which of these technologies is best for your specific needs. Resin printers cost a bit more in this area, since youll need to maintain a stock of disposable gloves and a solvent such as IPA to post-process prints. In these cases, resin can often be substantially faster for cases where you need a lot of parts. Heres why you can trust us. Then, you need to cure it under UV light. By For filament printers, parts typically use a meshed infill pattern, which saves material.

fdm sla filament recieve In the past, purchasing a resin 3D printer was substantially more expensive than a filament printer. FDM 3D printers are best known for their visible layers lines. Objects printed by SLA 3D printers have smooth surfaces, but often the quality depends upon the printer type. We have found that these types of repairs are fairly infrequent.

Use an SLA 3D printer if you're creating casting moulds for detailed products such as jewellery pieces and if model strength and durability aren't at the top of your priority list. To do so, youll need to carefully pour the resin from your vat back into the resin container, clean the vat out completely, and pour the new resin in the vat.

filament resin vs comparison printing 3d pla material depth usual budget choice Intriguing title, isn`t it? The print bed then rises slightly to let the next layer cure.

fdm sla photopolymer stampante integrating extrusion estrusione ibrida fotopolimero It all depends on the kind of printing you want to do.

tolerance filament Stereolithography Apparatus (SLA) technology. For that reason, they are much less likely to encounter mechanical issues. Resin printers should ideally be placed outside the residence (ie: garage, shed, or balcony) but they can be indoors in a separate and sealed room if they are being vented out a window. The only settings you will need to ever change are the layer time (how long each layer is exposed to the UV light to cure) and settings for support material. Filament Printer Top Pick: Creality Ender 3 V2. To get to the final product, you need to wash the resin off by immersing the part in isopropyl alcohol. Formlab's resins are $175-300 per kg and they are the typical ceiling for pricing - the exceptions to this are ceramic resins like those from Tethon that are designed for research. While the settings can be optimized to reduce issues such as stringing, it is nearly impossible to completely eliminate the quality defects.The resin miniature was printed using Siraya Tech Simple Smoky Black with the universal resin default of 0.05 mm layer height. Budget resins typically stay between $20-35 per kg, especially with the promos. When this occurs, you can either replace the film or get an entirely new vat for a fairly low cost. Resin 3D printers are best known for their high-detail and transparency. Such a nozzle will also increase the printing time for the filament printer. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Stereolithography (SLA)is the oldest form of 3D printing. Choosing the 3D printer that is right for youdepends on your needs and the objects that you are creating. 14/04/2022 Developed and originally implemented in the 1980s, FDM allows you to print operational prototypes as well as ready-to-use products as such LEGO, plastic gears and much more. 3D Printing with PLA is as safe as it gets. The Photon Mono 4K and M3 series are the newest generation.

Most consumer filaments max out around $150, while industrial filaments like PEEK can cost upwards of $500 per kg. The Ender 3 V2 offers a number of improvements over the original Ender 3, and due to its ease of use and low cost, it is our top recommendation for a first 3D printer. A large percentage of budget resins have low strength and fracture elongations, which explains why they are brittle. FDM printing is also very good at making practical prints. The internal components of the hot end tend to wear out over time since it is exposed to high temperatures. Since most lower cost resin printers use the DLP technology, we will focus on that technology in this article.

A layer of hardened material can be printed in a few seconds and quickly transferred to allow for printing of the next layer.

Overall, the cost of resin is higher per kilogram, but you will likely use less with a resin printer due to its smaller build size. Let us know! The strength, durability, and temperature resistance of resins and filaments are similar provided you are using the correct material for your application. By comparison, filament printer resolution is limited by the size of the opening in the nozzle where melted material is deposited, which is typically 0.4 mm (400 microns). We chose to showcase the Prusa Mk3 here because it is the perfect mix of price, advanced features, and quality prints. Keep reading to learn more about FDM vs SLA and how to choose the best 3D printer for your needs. Therefore, both types of 3D printers should be used in well-ventilated spaces. Overall, filament printers require a bit more maintenance, but there isnt a substantial difference here. FDM 3D printing results in the emission of toxic fumes and the use of high temperatures. If you get any resin on your skin, wash it off with soap and water as soon as possible - do not use IPA. Technology, thanks to 3D printing, has accessed even the fashion realms, and tailoring as we know it could change in the near future.

We have purchased many of these printers and have been very pleased with them.

filament 3d splicer joiner models makexyz multicoloured objects printed Now that you have a general idea of which technology is better for your needs, the next step is to take a look at a few printers in each category to learn more. These constructions will enable coral to grow upon them, which is considered as an accomplishment in helping tormented coral reefs from the various threats they face around the world. If you want production quality out of the machine or you are looking to print small models with a high level of detail, then we would suggest a resin, SLA/DLP printer.A great starter: Elegoo Mars Pro 2 (opens in new tab) ($400 at Amazon)The best of the best: Prusa Mk3 kit ($749 at Prusa Research).

fdm sla drucker gravur To compare FDM printersvia an interactive table, side-by-sides, and in-depth articles.Application & Safety FAQanswers common questions about resin.

resin bismaleimide 3d printer resins materials market inexpensive bmi fabbaloo development kerry stevenson hardware september indiegogo printing polymer polyurethane macro Similar to Filament printers, resin printers build parts in layers, but do so by exposing each slice to a pattern of UV light to solidify the resin in the desired locations. Read our breakdown below to compare. Filament printers have moving parts in all 3 axes, which means that over time, parts of the motion system will need replacement or tightening. Therefore, the latter material is usually recommended for beginners. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product.

filament hendrickson Which material you should use is entirely dependenton your application.

You can visit our FAQ page to find more safety guidelines and tips. The next layer is then placed on top of the previous layer. Ventilation Simulationshas animations for common DIY venting setups, andHeating Resin Printers during winter provides data for specific heat sources.Our Resin Print Settings Tablehas associated images, mixes, and does a resin giveaway.To browse resin properties and find your ideal strong, durable, flexible, or high-temp resin visit our Resin Properties Table. How to save our seas with 3D printing! Resin printing requires a lot more effort, especially when getting your resin model off the build platform. What is Digital Light Processing (DLP) 3D Printing?

3d filament splicer models makexyz

3d filament splicer models makexyz If possible, placing the printer outside the residence (ie: garage) will eliminate or minimize the need for ventilation or filtration. These individuals are among those leading the way in this relatively new and fascinating trade.

For higher end printers, resin tends to be more expensive. 13/05/2022 Another challenge with using resin is that changing materials can be time consuming.

While resin prints are much more detailed, they are fragile because resin 3D printing still has a long way to go when it comes to product strength. Weve heard stories of people getting serious burns from minutes of contact with the resin, however personally we have not ever had a reaction to small splashes on the skin that can sometimes occur (though we wash them off with soap as soon as it happens to be safe). He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games. Moreover, make sure that youalwaysuse Nitrile gloves when handling uncured materials and safety glasses to protect your eyes from toxic chemical by-products. Printers such as the Creality CR-10 and Ender 3 Max arrive mostly assembled, and only take around 15 minutes to assemble. You will also need PPE and some other equipment that we have listed out with prices, descriptions, and if they are required or optional. Parts printed from filament offer high durability, even when using standard plastics such as PLA. Seems that scientists found a way to assist coral reefs to rehabilitate, thus preventing their extinction, by using 3D printed structures! Most of the maintenance of filament printers relates to the filament path - the extruder which pushes filament, and the hot end which melts it before depositing it onto the part. This light source causes the impressive printing speeds because the amount of light allows the resin to quickly harden. Resin printers, however (specifically the DLP type) can print multiple objects just as fast as a single object, since the LCD is exposed to each layer for a fixed amount of time regardless of how many parts you are printing. When considering which of these types of 3D printers to purchase, youll first need to think about what types of objects you are planning to make. However, tensile strength and fracture elongation alone only gives most of the picture - the Izod test is used to determine how much energy a material can absorb under high-impact. We have had more success blending this resin with standard resins to balance these negative effects with the improved strength. It works by exposing a layer of photosensitive liquid resin to a UV-laser beam; the resin then hardens in the desired pattern, and the object is built layer by layer until it is complete. In this article, we will look at the tradeoffs of both filament and resin 3D printers to give you a good idea of which type is right for you. Standard resin printers have a much smaller build volume. With typical settings, filament printers can produce single objects much faster. Well look at some side by side comparisons to give you a general idea: Filament Printer: Creality Ender 3(view on Amazon), Resin Printer: Elegoo Mars(view on Amazon), Filament Printer: Creality CR10S Pro(view on Amazon), Upgraded features such as silent motors, unibody design, touch screen, all metal dual gear extruder, Resin Printer: Elegoo Saturn(view on Amazon), Upgraded features such as a high resolution LCD and dual linear rails, Industrial-grade components and warranty, wireless printing, 6K UHD LCD, warranty, Masked SLA technology for improved resolution and speed. Youll see two types of common resin printers, DLP (digital light processing) and SLA (Stereolithography).

sla stereolithography galvanometers movable Windows Central is part of Future US Inc, an international media group and leading digital publisher. But which is better for your project, and what equipment do you need? Total items: 0.00. This form of 3D printing is useful in all fields, from new product development to prototyping to end-product manufacturing. Youll also need to experiment with how models are oriented on the printer to get the best results.

Fused deposition modeling (FDM) is the style of printing you are likely most familiar with. Filament and an FDM printer is the right choice for hobbyists and makers, those building low-cost materials, when strength and durability are important or when precision and surface finish arent crucial. The material price of consumer resin and filament are nearly the same, $20-70/kg and $15-100/kg respectively. Digital Light Processing (DLP)is the fastest of all 3D printing methods.

To find properties of filaments, visit our FDM Properties Table. Strength & Properties of Filament vs Resin, wash & cure machine or an ultrasonic cleaner. You should not be able to see the layers on most resin prints. On the resin printed hand you can see webbing between the fingers - this is caused by overexposure and is easily fixed by reducing the exposure time per layer. For a first-time FDM 3D printer, you really can't do better than the Prusa Mk3.

Sitemap 21

Sitemap 21

This allows you to print a model with extremely fine detail.

This allows you to print a model with extremely fine detail.  resolution printing does 3d low left vs right filament

resolution printing does 3d low left vs right filament  Another smaller cost to consider is maintaining the 3D printer and making sure you have required supplies. All content copyright Creality Experts 2022. last updated 31 May 22, Windows Central's expert reviewers spend hours testing and comparing products and services so you can choose the best for you. For far less than you might think, you can have a resin printer that makes amazingly detailed models reliably. resin filament 3d photosensitive sunglass solution printed One of the super-sized printers we are looking forward to is the Prusa XL, which will be 360x360x360 mm and packed full of features such as 5 independent tool heads. However, there are a number of lower-cost resin machines on the market now using DLP technology. The price of a small resin printer is less than most FDM printers, but the additional equipment needed for resin makes the price of the entire setup similar. First, a very brief overview of how each of these technologies works: Filament printers build parts by melting plastic and depositing it into many stacked flat slices, or layers, which together form a 3D part. Consider supporting us via donation, referral links, or purchases! Find out more about how we test. Its advanced features and astounding print quality make it the best printer you can buy for under $1,000. Follow us and you will always be updated on the news! You can now buy an excellent wash and cure station that can speed up the curing process considerably, and Peopoly has released an enormous printer called the Phenom that will resin print your parts on a much larger scale. To compare resin printers, browse resin, and get equipment inspiration visit ourUltimate Resin Guide. sla resin sketchfab elegoo creality stereolithography dlp the3dprinterbee The answer is: it depends what you will be using it for. Filaments materials like OBC (Olefin Block Copolymers) and TPU (Thermoplastic Polyurethane) excel at flexibility. There was a problem. Filament printers form a thin layer with melted plastic, then lift the nozzle a small amount. We have a detailed guide on repairing these hot end issues, and feel that repairing the hot end is fairly simple. From the outside, these printers are very similar. This allows you to print a model with extremely fine detail, far more than a standard filament printer can produce, and the result tends to need far less post-processing work to give you a finished product. Like SLA, DLP 3D printers use liquid plastic resin, but instead of a UV-laser beam, the resin is melted with arc lamps. filament 3d resin printing vs wood printer comparison material depth slightly okay starting advanced materials let If you are hoping to print miniatures for board games, highly detailed models, or production-quality parts, then an SLA/DLP printer is the best choice. Strength is primarilywhylarge-scale manufacturers prefer FDM technology and strong filaments such as Polycarbonate. Moreover, filament parts don't need to undergo further processing.

Another smaller cost to consider is maintaining the 3D printer and making sure you have required supplies. All content copyright Creality Experts 2022. last updated 31 May 22, Windows Central's expert reviewers spend hours testing and comparing products and services so you can choose the best for you. For far less than you might think, you can have a resin printer that makes amazingly detailed models reliably. resin filament 3d photosensitive sunglass solution printed One of the super-sized printers we are looking forward to is the Prusa XL, which will be 360x360x360 mm and packed full of features such as 5 independent tool heads. However, there are a number of lower-cost resin machines on the market now using DLP technology. The price of a small resin printer is less than most FDM printers, but the additional equipment needed for resin makes the price of the entire setup similar. First, a very brief overview of how each of these technologies works: Filament printers build parts by melting plastic and depositing it into many stacked flat slices, or layers, which together form a 3D part. Consider supporting us via donation, referral links, or purchases! Find out more about how we test. Its advanced features and astounding print quality make it the best printer you can buy for under $1,000. Follow us and you will always be updated on the news! You can now buy an excellent wash and cure station that can speed up the curing process considerably, and Peopoly has released an enormous printer called the Phenom that will resin print your parts on a much larger scale. To compare resin printers, browse resin, and get equipment inspiration visit ourUltimate Resin Guide. sla resin sketchfab elegoo creality stereolithography dlp the3dprinterbee The answer is: it depends what you will be using it for. Filaments materials like OBC (Olefin Block Copolymers) and TPU (Thermoplastic Polyurethane) excel at flexibility. There was a problem. Filament printers form a thin layer with melted plastic, then lift the nozzle a small amount. We have a detailed guide on repairing these hot end issues, and feel that repairing the hot end is fairly simple. From the outside, these printers are very similar. This allows you to print a model with extremely fine detail, far more than a standard filament printer can produce, and the result tends to need far less post-processing work to give you a finished product. Like SLA, DLP 3D printers use liquid plastic resin, but instead of a UV-laser beam, the resin is melted with arc lamps. filament 3d resin printing vs wood printer comparison material depth slightly okay starting advanced materials let If you are hoping to print miniatures for board games, highly detailed models, or production-quality parts, then an SLA/DLP printer is the best choice. Strength is primarilywhylarge-scale manufacturers prefer FDM technology and strong filaments such as Polycarbonate. Moreover, filament parts don't need to undergo further processing.  Here are some 3D printed objects that caught our eye. To achieve the same printing standard using an FDM 3D printer, you would need to increase printing time, resulting in higher costs. We have two of these machines in our workshop and have seen impressive results considering the low price point. Items in cart: 0 Most filament printers require some assembly, but the difficulty can vary. The solvent will become clouded with resin and become ineffective after a a few uses and will need to be replaced and disposed of safely (you cant pour it down the drain). petg 3d filament printing Its important to consider the total down of ownership of a 3D printer, because the ongoing costs can be a more substantial portion of the total cost than the purchase price of the machine itself. Privacy policy sla dlp resin 3d The downside is that they tend to have smaller build plates than filament (FDM) printers, so you can't make large pieces on them. The printer repeats this process for each layer until the full part is formed. FDM (Fused Deposition Modelling) printersusefilaments, while resins are primarily used for Stereolithography Apparatus (SLA) technology. Have you ever thought about using 3D printing to Easter decorations? Check prices for the Elegoo Mars 2 Mono On Amazon here. User agreement Deciding whether to purchase an SLA 3D printer or an FDM 3D printer largely depends on what you're going to use it for. Resin 3D printing runs the risk of fume emission as well as unexpected chemical reactions. That's a good question.

Here are some 3D printed objects that caught our eye. To achieve the same printing standard using an FDM 3D printer, you would need to increase printing time, resulting in higher costs. We have two of these machines in our workshop and have seen impressive results considering the low price point. Items in cart: 0 Most filament printers require some assembly, but the difficulty can vary. The solvent will become clouded with resin and become ineffective after a a few uses and will need to be replaced and disposed of safely (you cant pour it down the drain). petg 3d filament printing Its important to consider the total down of ownership of a 3D printer, because the ongoing costs can be a more substantial portion of the total cost than the purchase price of the machine itself. Privacy policy sla dlp resin 3d The downside is that they tend to have smaller build plates than filament (FDM) printers, so you can't make large pieces on them. The printer repeats this process for each layer until the full part is formed. FDM (Fused Deposition Modelling) printersusefilaments, while resins are primarily used for Stereolithography Apparatus (SLA) technology. Have you ever thought about using 3D printing to Easter decorations? Check prices for the Elegoo Mars 2 Mono On Amazon here. User agreement Deciding whether to purchase an SLA 3D printer or an FDM 3D printer largely depends on what you're going to use it for. Resin 3D printing runs the risk of fume emission as well as unexpected chemical reactions. That's a good question.  Thank you for signing up to Windows Central. electromaker sla printers fdm If you are looking to buy a 3D printer for home use, there are two different technologies that you can choose from: Filament or Resin. Overall, resin printers are substantially easier to initially set up, due to their very simple assembly and simplicity of print settings. Entry level printers such as the Creality Halot-One and Elegoo Mars are standardized at 130 x 80 x 160 mm, while more premium large format Resin printers such as the Elegoo Saturn are 192 x 120 x 150 mm, which is still substantially smaller than even the entry level filament printers. You can explore brands, prices, and properties with our filament tables.

Thank you for signing up to Windows Central. electromaker sla printers fdm If you are looking to buy a 3D printer for home use, there are two different technologies that you can choose from: Filament or Resin. Overall, resin printers are substantially easier to initially set up, due to their very simple assembly and simplicity of print settings. Entry level printers such as the Creality Halot-One and Elegoo Mars are standardized at 130 x 80 x 160 mm, while more premium large format Resin printers such as the Elegoo Saturn are 192 x 120 x 150 mm, which is still substantially smaller than even the entry level filament printers. You can explore brands, prices, and properties with our filament tables.  While resin 3D printers are simple to get set up, the liquid resin adds some complications to using the printer.

While resin 3D printers are simple to get set up, the liquid resin adds some complications to using the printer.

The FEP film replacement is not too difficult but takes some time since there are a lot of screws securing it to the vat. The cheaper types of filament like PLA, PETG, and ABS will typically run $15-30 per kg. Resin printers can usually go down to 0.01 mm but even just the default provides an amazing level of detail. Entry level filament printers such as the Creality Ender 3 have a build volume of 220 x 220 x 250 mm, and many larger volume printers are available as well: Ender 3 Max: 300 x 300 x 350 mm (view on Amazon), CR-10 Max: 450 x 450 x 475 mm (view on Amazon). fdm 3d sla vs printer resin fff dlp printers filament comparing lcd types There are several key factors to consider when deciding whether an FDM or SLA/DLP printer is the right choice for you. James Bricknell These technologies differ in how they cure the resin: DLP printers use a UV LCD screen (basically a small monitor) to cure an entire layer at once, while SLA uses a focused laser which traces a path through each layer. It is a common misconception that FDM prints are always stronger than resin but this is simply not the case, as you can see in the graphs below - multiple properties need to be examined in order to get the whole picture. Once assembled, leveling the print bed can take a bit of trial and error. Resin and filament are the two most common materials used in 3D printing. DLP is a robust technology that produces high-resolution models every time, even allowing you to use cheaper materials for complex and detailed objects. It is possible to install smaller nozzles on filament printers, but the smallest viable nozzles are still 200 microns. Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. Engineering filaments such as PC, Nylon, and ASA blends can go for $50-100 per kg. Once solidified, the print bed rises a small amount, liquid resin flows into the gap, and the process repeats.

The FEP film replacement is not too difficult but takes some time since there are a lot of screws securing it to the vat. The cheaper types of filament like PLA, PETG, and ABS will typically run $15-30 per kg. Resin printers can usually go down to 0.01 mm but even just the default provides an amazing level of detail. Entry level filament printers such as the Creality Ender 3 have a build volume of 220 x 220 x 250 mm, and many larger volume printers are available as well: Ender 3 Max: 300 x 300 x 350 mm (view on Amazon), CR-10 Max: 450 x 450 x 475 mm (view on Amazon). fdm 3d sla vs printer resin fff dlp printers filament comparing lcd types There are several key factors to consider when deciding whether an FDM or SLA/DLP printer is the right choice for you. James Bricknell These technologies differ in how they cure the resin: DLP printers use a UV LCD screen (basically a small monitor) to cure an entire layer at once, while SLA uses a focused laser which traces a path through each layer. It is a common misconception that FDM prints are always stronger than resin but this is simply not the case, as you can see in the graphs below - multiple properties need to be examined in order to get the whole picture. Once assembled, leveling the print bed can take a bit of trial and error. Resin and filament are the two most common materials used in 3D printing. DLP is a robust technology that produces high-resolution models every time, even allowing you to use cheaper materials for complex and detailed objects. It is possible to install smaller nozzles on filament printers, but the smallest viable nozzles are still 200 microns. Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. Engineering filaments such as PC, Nylon, and ASA blends can go for $50-100 per kg. Once solidified, the print bed rises a small amount, liquid resin flows into the gap, and the process repeats.  Overall, filament printing is a better choice for functional parts, since it offers improved strength and more options for larger parts, which well look at next. If you are planning to print larger parts on your resin printer, you can reduce resin usage by making the parts hollow and including a drain hole to allow the unused resin in the center cavity to drain out. 3d sla formlabs printers form resin printer The Prusa Mini is the cheapest printer that can use these filaments without major modifications. 3D printing using resin is usually a lot messier than if you're using thermoplastic filaments. Resin printers themselves are usually cheaper than the FDM printers but the cost of the entire setup can be similar or moderately above. These printers can use materials such as PLA, PETG, PP, OBC, and TPU right out of the box. Here are some 3D printed objects that caught our eye. Best answer: If you're looking to make massive 3D-printed pieces or you want to finish your prints, then a filament printer is the best choice for you. 3d printers printing fff fdm printer resin vs dlp lcd fablab comparing sla fabrication customizable different If you are hoping to build large-scale models, cosplay items like armor or helmets, or you are looking to produce prototypes rapidly, then an FDM 3D printer is likely the right choice for you. Materials such as PETG, PP, ABS, ASA, Nylon, and PC have fairly high tensile strengths and fracture elongations, so parts printed from these filaments will be more durable than PLA or budget resin.

Overall, filament printing is a better choice for functional parts, since it offers improved strength and more options for larger parts, which well look at next. If you are planning to print larger parts on your resin printer, you can reduce resin usage by making the parts hollow and including a drain hole to allow the unused resin in the center cavity to drain out. 3d sla formlabs printers form resin printer The Prusa Mini is the cheapest printer that can use these filaments without major modifications. 3D printing using resin is usually a lot messier than if you're using thermoplastic filaments. Resin printers themselves are usually cheaper than the FDM printers but the cost of the entire setup can be similar or moderately above. These printers can use materials such as PLA, PETG, PP, OBC, and TPU right out of the box. Here are some 3D printed objects that caught our eye. Best answer: If you're looking to make massive 3D-printed pieces or you want to finish your prints, then a filament printer is the best choice for you. 3d printers printing fff fdm printer resin vs dlp lcd fablab comparing sla fabrication customizable different If you are hoping to build large-scale models, cosplay items like armor or helmets, or you are looking to produce prototypes rapidly, then an FDM 3D printer is likely the right choice for you. Materials such as PETG, PP, ABS, ASA, Nylon, and PC have fairly high tensile strengths and fracture elongations, so parts printed from these filaments will be more durable than PLA or budget resin.  This is because the nozzle must trace each part individually. Engineering resins can be $40-70 per kg. There are a few important factors to consider when choosing which of these technologies is best for your specific needs. Resin printers cost a bit more in this area, since youll need to maintain a stock of disposable gloves and a solvent such as IPA to post-process prints. In these cases, resin can often be substantially faster for cases where you need a lot of parts. Heres why you can trust us. Then, you need to cure it under UV light. By For filament printers, parts typically use a meshed infill pattern, which saves material. fdm sla filament recieve In the past, purchasing a resin 3D printer was substantially more expensive than a filament printer. FDM 3D printers are best known for their visible layers lines. Objects printed by SLA 3D printers have smooth surfaces, but often the quality depends upon the printer type. We have found that these types of repairs are fairly infrequent.

This is because the nozzle must trace each part individually. Engineering resins can be $40-70 per kg. There are a few important factors to consider when choosing which of these technologies is best for your specific needs. Resin printers cost a bit more in this area, since youll need to maintain a stock of disposable gloves and a solvent such as IPA to post-process prints. In these cases, resin can often be substantially faster for cases where you need a lot of parts. Heres why you can trust us. Then, you need to cure it under UV light. By For filament printers, parts typically use a meshed infill pattern, which saves material. fdm sla filament recieve In the past, purchasing a resin 3D printer was substantially more expensive than a filament printer. FDM 3D printers are best known for their visible layers lines. Objects printed by SLA 3D printers have smooth surfaces, but often the quality depends upon the printer type. We have found that these types of repairs are fairly infrequent.  Use an SLA 3D printer if you're creating casting moulds for detailed products such as jewellery pieces and if model strength and durability aren't at the top of your priority list. To do so, youll need to carefully pour the resin from your vat back into the resin container, clean the vat out completely, and pour the new resin in the vat. filament resin vs comparison printing 3d pla material depth usual budget choice Intriguing title, isn`t it? The print bed then rises slightly to let the next layer cure. fdm sla photopolymer stampante integrating extrusion estrusione ibrida fotopolimero It all depends on the kind of printing you want to do. tolerance filament Stereolithography Apparatus (SLA) technology. For that reason, they are much less likely to encounter mechanical issues. Resin printers should ideally be placed outside the residence (ie: garage, shed, or balcony) but they can be indoors in a separate and sealed room if they are being vented out a window. The only settings you will need to ever change are the layer time (how long each layer is exposed to the UV light to cure) and settings for support material. Filament Printer Top Pick: Creality Ender 3 V2. To get to the final product, you need to wash the resin off by immersing the part in isopropyl alcohol. Formlab's resins are $175-300 per kg and they are the typical ceiling for pricing - the exceptions to this are ceramic resins like those from Tethon that are designed for research. While the settings can be optimized to reduce issues such as stringing, it is nearly impossible to completely eliminate the quality defects.The resin miniature was printed using Siraya Tech Simple Smoky Black with the universal resin default of 0.05 mm layer height. Budget resins typically stay between $20-35 per kg, especially with the promos. When this occurs, you can either replace the film or get an entirely new vat for a fairly low cost. Resin 3D printers are best known for their high-detail and transparency. Such a nozzle will also increase the printing time for the filament printer. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Stereolithography (SLA)is the oldest form of 3D printing. Choosing the 3D printer that is right for youdepends on your needs and the objects that you are creating. 14/04/2022 Developed and originally implemented in the 1980s, FDM allows you to print operational prototypes as well as ready-to-use products as such LEGO, plastic gears and much more. 3D Printing with PLA is as safe as it gets. The Photon Mono 4K and M3 series are the newest generation.

Use an SLA 3D printer if you're creating casting moulds for detailed products such as jewellery pieces and if model strength and durability aren't at the top of your priority list. To do so, youll need to carefully pour the resin from your vat back into the resin container, clean the vat out completely, and pour the new resin in the vat. filament resin vs comparison printing 3d pla material depth usual budget choice Intriguing title, isn`t it? The print bed then rises slightly to let the next layer cure. fdm sla photopolymer stampante integrating extrusion estrusione ibrida fotopolimero It all depends on the kind of printing you want to do. tolerance filament Stereolithography Apparatus (SLA) technology. For that reason, they are much less likely to encounter mechanical issues. Resin printers should ideally be placed outside the residence (ie: garage, shed, or balcony) but they can be indoors in a separate and sealed room if they are being vented out a window. The only settings you will need to ever change are the layer time (how long each layer is exposed to the UV light to cure) and settings for support material. Filament Printer Top Pick: Creality Ender 3 V2. To get to the final product, you need to wash the resin off by immersing the part in isopropyl alcohol. Formlab's resins are $175-300 per kg and they are the typical ceiling for pricing - the exceptions to this are ceramic resins like those from Tethon that are designed for research. While the settings can be optimized to reduce issues such as stringing, it is nearly impossible to completely eliminate the quality defects.The resin miniature was printed using Siraya Tech Simple Smoky Black with the universal resin default of 0.05 mm layer height. Budget resins typically stay between $20-35 per kg, especially with the promos. When this occurs, you can either replace the film or get an entirely new vat for a fairly low cost. Resin 3D printers are best known for their high-detail and transparency. Such a nozzle will also increase the printing time for the filament printer. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Stereolithography (SLA)is the oldest form of 3D printing. Choosing the 3D printer that is right for youdepends on your needs and the objects that you are creating. 14/04/2022 Developed and originally implemented in the 1980s, FDM allows you to print operational prototypes as well as ready-to-use products as such LEGO, plastic gears and much more. 3D Printing with PLA is as safe as it gets. The Photon Mono 4K and M3 series are the newest generation.  Most consumer filaments max out around $150, while industrial filaments like PEEK can cost upwards of $500 per kg. The Ender 3 V2 offers a number of improvements over the original Ender 3, and due to its ease of use and low cost, it is our top recommendation for a first 3D printer. A large percentage of budget resins have low strength and fracture elongations, which explains why they are brittle. FDM printing is also very good at making practical prints. The internal components of the hot end tend to wear out over time since it is exposed to high temperatures. Since most lower cost resin printers use the DLP technology, we will focus on that technology in this article.

Most consumer filaments max out around $150, while industrial filaments like PEEK can cost upwards of $500 per kg. The Ender 3 V2 offers a number of improvements over the original Ender 3, and due to its ease of use and low cost, it is our top recommendation for a first 3D printer. A large percentage of budget resins have low strength and fracture elongations, which explains why they are brittle. FDM printing is also very good at making practical prints. The internal components of the hot end tend to wear out over time since it is exposed to high temperatures. Since most lower cost resin printers use the DLP technology, we will focus on that technology in this article.  A layer of hardened material can be printed in a few seconds and quickly transferred to allow for printing of the next layer.

A layer of hardened material can be printed in a few seconds and quickly transferred to allow for printing of the next layer.  Overall, the cost of resin is higher per kilogram, but you will likely use less with a resin printer due to its smaller build size. Let us know! The strength, durability, and temperature resistance of resins and filaments are similar provided you are using the correct material for your application. By comparison, filament printer resolution is limited by the size of the opening in the nozzle where melted material is deposited, which is typically 0.4 mm (400 microns). We chose to showcase the Prusa Mk3 here because it is the perfect mix of price, advanced features, and quality prints. Keep reading to learn more about FDM vs SLA and how to choose the best 3D printer for your needs. Therefore, both types of 3D printers should be used in well-ventilated spaces. Overall, filament printers require a bit more maintenance, but there isnt a substantial difference here. FDM 3D printing results in the emission of toxic fumes and the use of high temperatures. If you get any resin on your skin, wash it off with soap and water as soon as possible - do not use IPA. Technology, thanks to 3D printing, has accessed even the fashion realms, and tailoring as we know it could change in the near future.

Overall, the cost of resin is higher per kilogram, but you will likely use less with a resin printer due to its smaller build size. Let us know! The strength, durability, and temperature resistance of resins and filaments are similar provided you are using the correct material for your application. By comparison, filament printer resolution is limited by the size of the opening in the nozzle where melted material is deposited, which is typically 0.4 mm (400 microns). We chose to showcase the Prusa Mk3 here because it is the perfect mix of price, advanced features, and quality prints. Keep reading to learn more about FDM vs SLA and how to choose the best 3D printer for your needs. Therefore, both types of 3D printers should be used in well-ventilated spaces. Overall, filament printers require a bit more maintenance, but there isnt a substantial difference here. FDM 3D printing results in the emission of toxic fumes and the use of high temperatures. If you get any resin on your skin, wash it off with soap and water as soon as possible - do not use IPA. Technology, thanks to 3D printing, has accessed even the fashion realms, and tailoring as we know it could change in the near future.  We have purchased many of these printers and have been very pleased with them. filament 3d splicer joiner models makexyz multicoloured objects printed Now that you have a general idea of which technology is better for your needs, the next step is to take a look at a few printers in each category to learn more. These constructions will enable coral to grow upon them, which is considered as an accomplishment in helping tormented coral reefs from the various threats they face around the world. If you want production quality out of the machine or you are looking to print small models with a high level of detail, then we would suggest a resin, SLA/DLP printer.A great starter: Elegoo Mars Pro 2 (opens in new tab) ($400 at Amazon)The best of the best: Prusa Mk3 kit ($749 at Prusa Research). fdm sla drucker gravur To compare FDM printersvia an interactive table, side-by-sides, and in-depth articles.Application & Safety FAQanswers common questions about resin. resin bismaleimide 3d printer resins materials market inexpensive bmi fabbaloo development kerry stevenson hardware september indiegogo printing polymer polyurethane macro Similar to Filament printers, resin printers build parts in layers, but do so by exposing each slice to a pattern of UV light to solidify the resin in the desired locations. Read our breakdown below to compare. Filament printers have moving parts in all 3 axes, which means that over time, parts of the motion system will need replacement or tightening. Therefore, the latter material is usually recommended for beginners. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product. filament hendrickson Which material you should use is entirely dependenton your application.

We have purchased many of these printers and have been very pleased with them. filament 3d splicer joiner models makexyz multicoloured objects printed Now that you have a general idea of which technology is better for your needs, the next step is to take a look at a few printers in each category to learn more. These constructions will enable coral to grow upon them, which is considered as an accomplishment in helping tormented coral reefs from the various threats they face around the world. If you want production quality out of the machine or you are looking to print small models with a high level of detail, then we would suggest a resin, SLA/DLP printer.A great starter: Elegoo Mars Pro 2 (opens in new tab) ($400 at Amazon)The best of the best: Prusa Mk3 kit ($749 at Prusa Research). fdm sla drucker gravur To compare FDM printersvia an interactive table, side-by-sides, and in-depth articles.Application & Safety FAQanswers common questions about resin. resin bismaleimide 3d printer resins materials market inexpensive bmi fabbaloo development kerry stevenson hardware september indiegogo printing polymer polyurethane macro Similar to Filament printers, resin printers build parts in layers, but do so by exposing each slice to a pattern of UV light to solidify the resin in the desired locations. Read our breakdown below to compare. Filament printers have moving parts in all 3 axes, which means that over time, parts of the motion system will need replacement or tightening. Therefore, the latter material is usually recommended for beginners. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product. filament hendrickson Which material you should use is entirely dependenton your application.  You can visit our FAQ page to find more safety guidelines and tips. The next layer is then placed on top of the previous layer. Ventilation Simulationshas animations for common DIY venting setups, andHeating Resin Printers during winter provides data for specific heat sources.Our Resin Print Settings Tablehas associated images, mixes, and does a resin giveaway.To browse resin properties and find your ideal strong, durable, flexible, or high-temp resin visit our Resin Properties Table. How to save our seas with 3D printing! Resin printing requires a lot more effort, especially when getting your resin model off the build platform. What is Digital Light Processing (DLP) 3D Printing?

You can visit our FAQ page to find more safety guidelines and tips. The next layer is then placed on top of the previous layer. Ventilation Simulationshas animations for common DIY venting setups, andHeating Resin Printers during winter provides data for specific heat sources.Our Resin Print Settings Tablehas associated images, mixes, and does a resin giveaway.To browse resin properties and find your ideal strong, durable, flexible, or high-temp resin visit our Resin Properties Table. How to save our seas with 3D printing! Resin printing requires a lot more effort, especially when getting your resin model off the build platform. What is Digital Light Processing (DLP) 3D Printing?  3d filament splicer models makexyz If possible, placing the printer outside the residence (ie: garage) will eliminate or minimize the need for ventilation or filtration. These individuals are among those leading the way in this relatively new and fascinating trade.

3d filament splicer models makexyz If possible, placing the printer outside the residence (ie: garage) will eliminate or minimize the need for ventilation or filtration. These individuals are among those leading the way in this relatively new and fascinating trade.  For higher end printers, resin tends to be more expensive. 13/05/2022 Another challenge with using resin is that changing materials can be time consuming.

For higher end printers, resin tends to be more expensive. 13/05/2022 Another challenge with using resin is that changing materials can be time consuming.  While resin prints are much more detailed, they are fragile because resin 3D printing still has a long way to go when it comes to product strength. Weve heard stories of people getting serious burns from minutes of contact with the resin, however personally we have not ever had a reaction to small splashes on the skin that can sometimes occur (though we wash them off with soap as soon as it happens to be safe). He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games. Moreover, make sure that youalwaysuse Nitrile gloves when handling uncured materials and safety glasses to protect your eyes from toxic chemical by-products. Printers such as the Creality CR-10 and Ender 3 Max arrive mostly assembled, and only take around 15 minutes to assemble. You will also need PPE and some other equipment that we have listed out with prices, descriptions, and if they are required or optional. Parts printed from filament offer high durability, even when using standard plastics such as PLA. Seems that scientists found a way to assist coral reefs to rehabilitate, thus preventing their extinction, by using 3D printed structures! Most of the maintenance of filament printers relates to the filament path - the extruder which pushes filament, and the hot end which melts it before depositing it onto the part. This light source causes the impressive printing speeds because the amount of light allows the resin to quickly harden. Resin printers, however (specifically the DLP type) can print multiple objects just as fast as a single object, since the LCD is exposed to each layer for a fixed amount of time regardless of how many parts you are printing. When considering which of these types of 3D printers to purchase, youll first need to think about what types of objects you are planning to make. However, tensile strength and fracture elongation alone only gives most of the picture - the Izod test is used to determine how much energy a material can absorb under high-impact. We have had more success blending this resin with standard resins to balance these negative effects with the improved strength. It works by exposing a layer of photosensitive liquid resin to a UV-laser beam; the resin then hardens in the desired pattern, and the object is built layer by layer until it is complete. In this article, we will look at the tradeoffs of both filament and resin 3D printers to give you a good idea of which type is right for you. Standard resin printers have a much smaller build volume. With typical settings, filament printers can produce single objects much faster. Well look at some side by side comparisons to give you a general idea: Filament Printer: Creality Ender 3(view on Amazon), Resin Printer: Elegoo Mars(view on Amazon), Filament Printer: Creality CR10S Pro(view on Amazon), Upgraded features such as silent motors, unibody design, touch screen, all metal dual gear extruder, Resin Printer: Elegoo Saturn(view on Amazon), Upgraded features such as a high resolution LCD and dual linear rails, Industrial-grade components and warranty, wireless printing, 6K UHD LCD, warranty, Masked SLA technology for improved resolution and speed. Youll see two types of common resin printers, DLP (digital light processing) and SLA (Stereolithography). sla stereolithography galvanometers movable Windows Central is part of Future US Inc, an international media group and leading digital publisher. But which is better for your project, and what equipment do you need? Total items: 0.00. This form of 3D printing is useful in all fields, from new product development to prototyping to end-product manufacturing. Youll also need to experiment with how models are oriented on the printer to get the best results.

While resin prints are much more detailed, they are fragile because resin 3D printing still has a long way to go when it comes to product strength. Weve heard stories of people getting serious burns from minutes of contact with the resin, however personally we have not ever had a reaction to small splashes on the skin that can sometimes occur (though we wash them off with soap as soon as it happens to be safe). He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games. Moreover, make sure that youalwaysuse Nitrile gloves when handling uncured materials and safety glasses to protect your eyes from toxic chemical by-products. Printers such as the Creality CR-10 and Ender 3 Max arrive mostly assembled, and only take around 15 minutes to assemble. You will also need PPE and some other equipment that we have listed out with prices, descriptions, and if they are required or optional. Parts printed from filament offer high durability, even when using standard plastics such as PLA. Seems that scientists found a way to assist coral reefs to rehabilitate, thus preventing their extinction, by using 3D printed structures! Most of the maintenance of filament printers relates to the filament path - the extruder which pushes filament, and the hot end which melts it before depositing it onto the part. This light source causes the impressive printing speeds because the amount of light allows the resin to quickly harden. Resin printers, however (specifically the DLP type) can print multiple objects just as fast as a single object, since the LCD is exposed to each layer for a fixed amount of time regardless of how many parts you are printing. When considering which of these types of 3D printers to purchase, youll first need to think about what types of objects you are planning to make. However, tensile strength and fracture elongation alone only gives most of the picture - the Izod test is used to determine how much energy a material can absorb under high-impact. We have had more success blending this resin with standard resins to balance these negative effects with the improved strength. It works by exposing a layer of photosensitive liquid resin to a UV-laser beam; the resin then hardens in the desired pattern, and the object is built layer by layer until it is complete. In this article, we will look at the tradeoffs of both filament and resin 3D printers to give you a good idea of which type is right for you. Standard resin printers have a much smaller build volume. With typical settings, filament printers can produce single objects much faster. Well look at some side by side comparisons to give you a general idea: Filament Printer: Creality Ender 3(view on Amazon), Resin Printer: Elegoo Mars(view on Amazon), Filament Printer: Creality CR10S Pro(view on Amazon), Upgraded features such as silent motors, unibody design, touch screen, all metal dual gear extruder, Resin Printer: Elegoo Saturn(view on Amazon), Upgraded features such as a high resolution LCD and dual linear rails, Industrial-grade components and warranty, wireless printing, 6K UHD LCD, warranty, Masked SLA technology for improved resolution and speed. Youll see two types of common resin printers, DLP (digital light processing) and SLA (Stereolithography). sla stereolithography galvanometers movable Windows Central is part of Future US Inc, an international media group and leading digital publisher. But which is better for your project, and what equipment do you need? Total items: 0.00. This form of 3D printing is useful in all fields, from new product development to prototyping to end-product manufacturing. Youll also need to experiment with how models are oriented on the printer to get the best results.  Fused deposition modeling (FDM) is the style of printing you are likely most familiar with. Filament and an FDM printer is the right choice for hobbyists and makers, those building low-cost materials, when strength and durability are important or when precision and surface finish arent crucial. The material price of consumer resin and filament are nearly the same, $20-70/kg and $15-100/kg respectively. Digital Light Processing (DLP)is the fastest of all 3D printing methods.

Fused deposition modeling (FDM) is the style of printing you are likely most familiar with. Filament and an FDM printer is the right choice for hobbyists and makers, those building low-cost materials, when strength and durability are important or when precision and surface finish arent crucial. The material price of consumer resin and filament are nearly the same, $20-70/kg and $15-100/kg respectively. Digital Light Processing (DLP)is the fastest of all 3D printing methods.  To find properties of filaments, visit our FDM Properties Table. Strength & Properties of Filament vs Resin, wash & cure machine or an ultrasonic cleaner. You should not be able to see the layers on most resin prints. On the resin printed hand you can see webbing between the fingers - this is caused by overexposure and is easily fixed by reducing the exposure time per layer. For a first-time FDM 3D printer, you really can't do better than the Prusa Mk3.

To find properties of filaments, visit our FDM Properties Table. Strength & Properties of Filament vs Resin, wash & cure machine or an ultrasonic cleaner. You should not be able to see the layers on most resin prints. On the resin printed hand you can see webbing between the fingers - this is caused by overexposure and is easily fixed by reducing the exposure time per layer. For a first-time FDM 3D printer, you really can't do better than the Prusa Mk3.