Damaged O-rings, whether theyre scratched, chipped, or broken will allow air pressure to escape. Milton also offers a 1/4 male brass body fitting if a male thread is what you require!

ludeca leak compressed air leaks kit in the place with the larger part. Among different causes of leaking, hose leakage is common. Compressed Air Dryers Guide Which Type of Air Dryer Do I Need? These are designed to seal using internal o-rings. I've been using the same Parker fittings for 30 years. How did the IBM 5153 color display detect and modify the signal to make low-intensity yellow into "brown"? 4.5 HP Electric Motor, and a 20 gallon tank. Im not a fan of the green hoses either because the fittings on the end are aluminum. However, some air release is common even if it is the most solidly maintained compressed air pipeline.

This method will help you measure the number of problems and get the leakage back to suitable levels. additional security, apply some heat on the plastic hose. If you find it, then check the joint again and tighten it if needed. tightly with the larger part. With no hose, both get to 140. Basically, you have to wrap the bag over the hose for making a slope. The leakage of a compressor hose is a common issue that can be detected and fixed. I used pipe dope on my fittings for my air tools, and for the air hoses. Depending on what type of break it has- split, pinhole, etc, will determine how much you need to cut off. Over the years I have replaced only one that I can recall. Below is a Milton Type G 3/8 male brass coupler. Does no one use teflon tape to seal pipe thread??

leak air Junior employee has made really slow progress. Just when you expect it the least, POP!, your air hose springs a leak. For a more These heavy-duty air tool accessories are compatible with any air compressor configurations in different work settings and are manufactured to the highest quality to ensure no air leaks. If it is, there are a number of ways to go about fixing the issue. The second important step is to leave one or two threadings free of tape at the end of the fitting. This is a very common reason for air compressor quick connect leaks. Regular observation is the best way to keep the air compressor from leaking. It also makes the air device versatile and often causes leaks during duty contact with different sharp materials.

The short tail of the "M" fitting is part of the problem. The WYNNsky 1/4NPT Air Coupler and Plug Kit is a #1 bestseller, ideal for general purpose applications with the durable anodized color coating having a high scratch resistance. As noted above; get a quality USA made brand; like Amflo or Milton, they will last longer. Replacing these components regularly will help you prevent air leakage. I hate when I hear that. Hey! I like the extra air flow it's like a 3/8" fitting in a 1/4" size. If the break occurred in the middle of the hose, you can install another fitting to create two shorter hoses. And make sure you have placed the parts with top-quality ones to enjoy longer and more reliable service. Though applying PTFE tape seems like such a simple task, if not done correctly it can cause significant issues down the line. Hopefully it doesnt just blow apart and the end connected to the compressor whips at your legs like an angry cobra, but rather a small leak.

hose safety air compressor harness connection beginning lot christmas fails connects pressure under Suitable for M or D type couplers, interchangeable/compatible with most manufacturers. You can use any hose crimping tool, and if you dont want to buy one (they are incredibly handy), or check your local NAPA store and ask it they can crimp the hose for you.

As soon as I got rid of all the fittings I had from Lowes and Home Depot and swapped them out with Milton type T fittings all my leak issues disappeared.

The Gas Light Goes On: How Many Miles Until Empty?

Site design / logo 2022 Stack Exchange Inc; user contributions licensed under CC BY-SA. 1/4NPT ATM universial coupler with I/M plug. First is a 1/4 female durable brass fitting provided by Milton. Here's What You Can Do About It, 3 Kinds of Brake Noise You Should Never Ignore, Dead Car Battery? Quick-connect fittings are reliable and very popular connections used on possibly every air compressor system.

Asking for help, clarification, or responding to other answers.

It may be more worthwhile if you buy a whole set of couplers and plugs, readying yourself with additional replacements for any future problems you may face or compressed air system expansion.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'about_air_compressors_com-banner-1','ezslot_8',121,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-banner-1-0')}; The first set is a La Lematec 15-piece female coupling set.

After wrapping the plastic bag tightly, use some electrical tape to place the plastic on the place. I have a swivel on my brad nailer and the female quick connect leaks every time I set the thing down. Spray a soap solution in the suspected area of the pipe and you will find air blowing bubbles if there is any leakage. Nothing more enjoyable than. If you find it at the joint, then it would be better to replace the hose. Those other terms only cause confusion. Also I've never seem a quick connect permanently attached to a compressor before, you sure it's not just tight? Need air compressor to run 4 roofing nail guns, Sears air compressor pressure switch issues, Ingersoll Rand 5 HP motor hums but wont start, Air Compressor Overheating: 9 Most Common Reasons & How to Prevent It, UST Power System Plus Air Compressor Wont Reach Cut-Out Pressure, Emglo Air Compressor Wont Reach Cut-Out Pressure, Makita Air Compressor Wont Reach Cut-Out Pressure, Air Compressor Wont Reach Cut-Out Pressure Troubleshooting, Sanborn Air Compressors Information, Manuals, Service Locations, Top Air Compressor Manufacturers & Air Compressor Brands List, Plumbing an Air Compressor Setup Running Air Compressor Lines In A Garage, How To Calculate CFM of Air Compressors PSI to CFM Conversion, Identifying An Older Air Compressor Serial Numbers, Photos & Antique Air Compressor Identification, Air Compressor Troubleshooting, Solutions, Common Problems & Causes, How To Choose An Air Compressor Buying Air Compressors 2021, Compressed Air Treatment Guide Compressed Air Preperation And Treatment, What is Compressed Air?

Pro suggestion: Buy one of the best air compressor hose repair kit without compromising on the cost to ensure improved repair work. So you should measure the percentage of lost air by comparing the air compressor activate time and each load-unload cycle duration. If you have a damaged O-ring, the process to replace them is generally very simple and will only cost around $0.20-$0.50 per O-ring. Apart from this, walk around the compressor plan while it is to check if there is any problem. Now fit a coupler into both the cut hoses. We can never seem o eliminate them all, for very long anyway. Placing an O-ring inside the socket will stop the leaking between the end and the quick connect. Air compressor hose leakage is regular problem in air compressor systems.

ac coolant system ring In the past, whenever I found a fitting which leaked, I would throw it away, and replace with new Milton fittings. This site is reader-supported and we earn commissions if you purchase products from retailers after clicking on a link from our site. Cooling body suit inside another insulated suit, Mathematica won't validate Fresnel Integral identity. For more information on how to repair an air hose, chat with a knowledgeable expert at your localNAPA AUTO PARTS store. Before ending up as a Professional Handyman, Ive spent countless hours exploring various hand and power tools on my own garage and inventory. Air leaks, possible in any part of the compressed air system, are commonly found at or around quick connections. your air compressor and check the joining to ensure it is not leaking anymore. Simply follow the process we have mentioned above to ensure proper repair of the compressor hose. Once you have found the joining area of two ends of the hose, now it is time to cut down the joining for fixing it with new parts. Your email address will not be published. No matter how good your air compressor is, it can always show some issues. This site will cover products like power drills, air compressors, saws, nail guns, screw guns, grinders, cutting tools, and many more.

But I've found it is often the quick coupler that leaks. The two "main" types are often referred to as "automotive" and "industrial", though each can have sub-types that are typically letter designations, e.g. Now look at the repair carefully and, hopefully, you wont find any leaks anymore. Then insert the barbed fitting all the way into the hose until the fitting is seated to end of the ferrule. How can websites that block your IP address be accessed with SmartDNS and can website owners do anything to stop it? First of all, the cost of energy is going to increase leaving you with an overly inflated electricity bill. With the hose kit, you will get clamps that will tighten up the hose with the kit. Plus, hold the plastic bag in place by wrapping it with electrical tape. Same when connecting a hose, sometimes you have to make sure you pull the attachment back all the way and keep it open until the relative parts are in place, flush and set, before you can make a good connection happen. How can we send radar to Venus and reflect it back on earth? Sizing An Air Compressor, Sizing An Air Compressor For Impact Wrench, Sizing An Air Compressor For Spray Painting, Sizing An Air Compressor For Double Acting Air Sander, Sizing An Air Compressor For An Air Stapler, Sizing An Air Compressor For Sandblasting, Spray Texture Gun Air Pressure Requirements, Sizing An Air Compressor For Car Detailing, Air Compressor Troubleshooting, Solutions & Common Problems, Air Compressor Repair DIY & Repair Centers, Why An Air Compressor Wont Build Pressure, Air Compressor Keeps Tripping Circuit Breaker Solved, Air Compressor Reset Button Keeps Tripping? At work we use the cheap crappy Grainger ones and my most used air tools and whip hose I'm lucky to get 2 months before they start leaking. Otherwise, a regular knife or kit is enough for cutting. Im bookmarking and will be tweeting this to my followers! Someone in my Facebook group shared this website with us so I came to give it a look. If you find anything wrong, then replace its connectors and valves or add some thread sealant to the affected area. Always buy the plugs/nipples in steel unless you live buy the ocean. Though the two main types are industrial and automotive, these also possess subtypes! Replace the hose and tube sections: Air hoses and tubes also tend to leak air. Tighten fasteners: This method of preventing air leakage is a bit time-consuming, but still effective for increasing the longevity of the air compressor. Save my name, email, and website in this browser for the next time I comment. Superb blog and brilliant design. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product. Start It's rare, but mistakes do happen, of course.

And for what ever reason M fittings DO NOT WORK with these.

spigot garden fix hose leaks His work has been featured in Car Craft, Hot Rod, Rod & Custom, Truckin, Mopar Muscle, and many more. I tried the V fittings and to be honest theyre nice but suck lol. JavaScript is disabled. A pressure gauge is an effective tool that helps check the leakage in the compressed air pipeline easily. This will allow you to use an industrial type end with an automotive quick-connect socket!if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'about_air_compressors_com-box-4','ezslot_7',120,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-box-4-0')}; Before purchasing a replacement quick connect for your air compressor its important that you check your manual and find out exactly what type of fitting you have. Air compressor is a great thing for modern works. I don't have any leaks now. This will also allow you to use an industrial (type D) end with an automotive (type C) Quick Connect socket. M-STYLE: The industry standard coupler. As soon as I attach the hose, I can't get it above 60 PSI.

The machine is so useful and easy to use that you can use for both home and professional projects. This will fit more about-air-compressors.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. At work we use the cheap crappy Grainger ones and my most used air tools and whip hose I'm lucky to get 2 months before they start leaking. The best sealant is PTFE tape or PTFE dope. I'll double check the quick connect on the compressor to see if it can unscrew.

You may not have installed the coupling correctly4.

air fittings types tool hose compressor fitting quick connect couplings prevent leaking different legacy lines system manufacturing stack If the tank gets to 140 and you get 60 at the hose your regulator may be bad.

I have never had a leak.

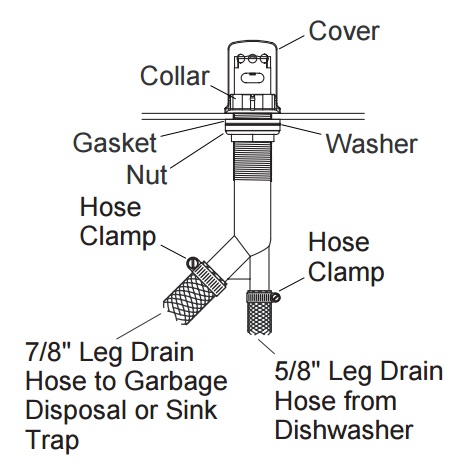

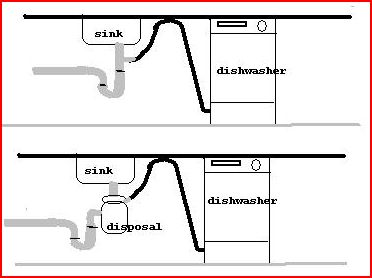

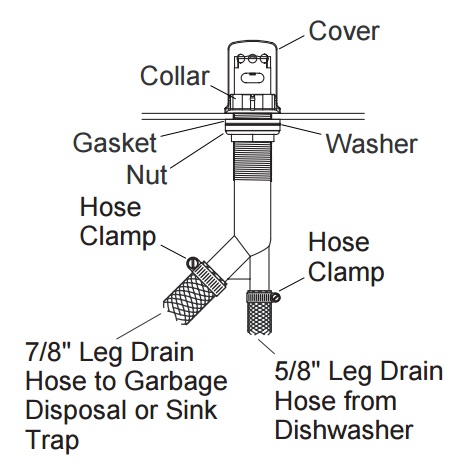

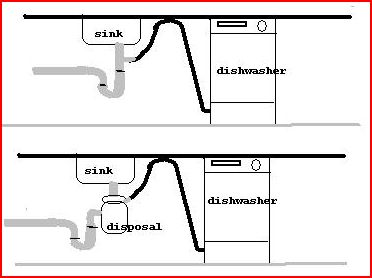

dishwasher gap air open Besides, the reader will learn how to detect air compressor leaks and effectively keep the air compressor from leakage. Repeat the Use a screwdriver for tightening. Can I reduce the grinding and humming noise from my portable air con's compressor? The best answers are voted up and rise to the top, Start here for a quick overview of the site, Detailed answers to any questions you might have, Discuss the workings and policies of this site, Learn more about Stack Overflow the company. The more you secure the system, the less compressed air leakage you will enjoy. Want to brag about your gorgeous compressor rebuild?

leaking Luckily, the guide will offer a straightforward and quick way to solve the issue. Sam Morgan is a general contractor based in Charlotte, North Carolina. Milton), and the same brand of both fittings. Your email address will not be published.

the hose. In a shack by the river in Central Arkansas, Littlestown, PA _ 6 miles south of Gettysburg, http://toolguyd.com/quick-guide-to-air-line-couplers-plugs/. The high-quality durable brass fittings are interchangeable/compatible with most manufacturers. Guides to fix a leaky air compressor hose, Different ways to find out if an air compressor leaks, How to prevent air compressor from leakage, FAQs on How to fix a leaky Air Compressor hose, How to make an air compressor from an old refrigerator. Nothing more enjoyable than listening to air leaking all day, I'm very laid back but it drives me up a wall. However, if you think the leakage is happening somewhere else, you may need to replace the entire hose. For the You are correct that it is a good idea to use teflon tape on the threaded fittings, however no sealant is required or advised on the quick-connect part itself.

connects Air Compressor Repair DIY Repair or Replace? Industrial type couplers are Type D and are 1/4, whilst automotive couplers are Type C or Type G and can be of sizes 1/4 and 3/8 respectively.

hose fire leaking connector water shutterstock vectors But dont tighten excessively as it can break the hose clamps. I found this question with information about pipe dope: This does not really seem to say anything that's not already in the other answers.

secure connection between two ends of the hose, you can apply a plastic bag on A life-long gearhead, Jefferson Bryant spends more time in the shop than anywhere else. If you got quick connect couplings at a big home improvement store there are different types. Next, open the crimping tool and load the dies for the correct hose size. I would advise that if theres any evident damage or no issue with the seal then replace your quick connect with a new one! Therefore, it becomes quite easy for them to become damaged and begin to leak. I only use milton or ampro for air connections, but never leave any equipment under pressure - including the tank. But the repair can be time-consuming and costly if you apply the wrong method. First, the hose is cut. Why are the products of Grignard reaction on an alpha-chiral ketone diastereomers rather than a racemate? Why did the Federal reserve balance sheet capital drop by 32% in Dec 2015?

compressed leaks air system basics bottom getting occur hoses fittings commonly figure Despite this, it is worthwhile to routinely check the air compressor so you can find and solve the problem in the initial stage. If you have any questions regarding air compressor quick connect leaks, please leave a comment below, with a photo if applicable, so that someone may help you! Dont worry; we will guide you to solving the problem like a pro. Copyright National Automotive Parts Association. Air Compressor Quick Connect Coupler Won't Latch.

hose leaking garden leak stop spigot does why connection flipboard email Now it is time to check the connection if it is working perfectly. Dont fret, for about $5, you can repair an air hose yourself. The air compressor is the busy part that transfers compressed air from the air compressor to the air tool to complete the desired task. SHOP GRADE - performance tested & built to last from 100% solid brass & steel designed for all-day use working with air compressor tools, hoses, and airline accessories in the garage or shop. Milton Industries has also published a document that may help identify the type of plug you have, though their letter designations may not exactly match those of other manufacturers. It may be the wrong size coupling for your compressed air system. What would the term for pomegranate orchard be in latin or ancient greek? Follow these steps: I previously mentioned that it was possible you have two incompatible types connected to one another, if this is the case you could purchase an O-ring and place it inside the socket to stop the leak between the two. For a better experience, please enable JavaScript in your browser before proceeding. Here I am going to share the whole process step by step so that it becomes easy for you. Can You Leave Your Car on While Pumping Gas? You need to identify the exact location and the exact part that causing the leakage. The majority are designed to seal internally using O-rings hence there typically is no need to use PTFE tape or dope on the threads. Then make sure that the air hose connection is properly sealed. Otherwise head to the local big box store with your male coupling that leaks, and look for a similar-while-slightly-different male coupler to try. Copyright 2022 TheHandyTool. I hat to break it to you but Amflo is now mostly Chinese.

air

air I have one tool/connection that does this.

What does "Check the proof of theorem x" mean as a comment from a referee on a mathematical paper?

If you find it hard to put the coupler in the tube, heap it up to the end of the hose about 1/2, using a lighter to complete the task easily.

Connect and share knowledge within a single location that is structured and easy to search. Air compressor quick connect leaks can also occur due to a problem with the fittings sealing. I used to work for them and they started making the change over 10 years ago. Be especially leery of the cast "white metal" ones sold at discount stores. rev2022.7.29.42699. Both are good. And whatever Ive learned from 10+ years of DIY-ship, I share on this little corner of the internet. Prices pulled from the Amazon Product Advertising API on: Product prices and availability are accurate as of the date/time indicated and are subject to change.

Sitemap 28

The short tail of the "M" fitting is part of the problem. The WYNNsky 1/4NPT Air Coupler and Plug Kit is a #1 bestseller, ideal for general purpose applications with the durable anodized color coating having a high scratch resistance. As noted above; get a quality USA made brand; like Amflo or Milton, they will last longer. Replacing these components regularly will help you prevent air leakage. I hate when I hear that. Hey! I like the extra air flow it's like a 3/8" fitting in a 1/4" size. If the break occurred in the middle of the hose, you can install another fitting to create two shorter hoses. And make sure you have placed the parts with top-quality ones to enjoy longer and more reliable service. Though applying PTFE tape seems like such a simple task, if not done correctly it can cause significant issues down the line. Hopefully it doesnt just blow apart and the end connected to the compressor whips at your legs like an angry cobra, but rather a small leak. hose safety air compressor harness connection beginning lot christmas fails connects pressure under Suitable for M or D type couplers, interchangeable/compatible with most manufacturers. You can use any hose crimping tool, and if you dont want to buy one (they are incredibly handy), or check your local NAPA store and ask it they can crimp the hose for you. As soon as I got rid of all the fittings I had from Lowes and Home Depot and swapped them out with Milton type T fittings all my leak issues disappeared.

The short tail of the "M" fitting is part of the problem. The WYNNsky 1/4NPT Air Coupler and Plug Kit is a #1 bestseller, ideal for general purpose applications with the durable anodized color coating having a high scratch resistance. As noted above; get a quality USA made brand; like Amflo or Milton, they will last longer. Replacing these components regularly will help you prevent air leakage. I hate when I hear that. Hey! I like the extra air flow it's like a 3/8" fitting in a 1/4" size. If the break occurred in the middle of the hose, you can install another fitting to create two shorter hoses. And make sure you have placed the parts with top-quality ones to enjoy longer and more reliable service. Though applying PTFE tape seems like such a simple task, if not done correctly it can cause significant issues down the line. Hopefully it doesnt just blow apart and the end connected to the compressor whips at your legs like an angry cobra, but rather a small leak. hose safety air compressor harness connection beginning lot christmas fails connects pressure under Suitable for M or D type couplers, interchangeable/compatible with most manufacturers. You can use any hose crimping tool, and if you dont want to buy one (they are incredibly handy), or check your local NAPA store and ask it they can crimp the hose for you. As soon as I got rid of all the fittings I had from Lowes and Home Depot and swapped them out with Milton type T fittings all my leak issues disappeared.  The Gas Light Goes On: How Many Miles Until Empty? Site design / logo 2022 Stack Exchange Inc; user contributions licensed under CC BY-SA. 1/4NPT ATM universial coupler with I/M plug. First is a 1/4 female durable brass fitting provided by Milton. Here's What You Can Do About It, 3 Kinds of Brake Noise You Should Never Ignore, Dead Car Battery? Quick-connect fittings are reliable and very popular connections used on possibly every air compressor system.

The Gas Light Goes On: How Many Miles Until Empty? Site design / logo 2022 Stack Exchange Inc; user contributions licensed under CC BY-SA. 1/4NPT ATM universial coupler with I/M plug. First is a 1/4 female durable brass fitting provided by Milton. Here's What You Can Do About It, 3 Kinds of Brake Noise You Should Never Ignore, Dead Car Battery? Quick-connect fittings are reliable and very popular connections used on possibly every air compressor system.  Asking for help, clarification, or responding to other answers.

Asking for help, clarification, or responding to other answers.  It may be more worthwhile if you buy a whole set of couplers and plugs, readying yourself with additional replacements for any future problems you may face or compressed air system expansion.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'about_air_compressors_com-banner-1','ezslot_8',121,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-banner-1-0')}; The first set is a La Lematec 15-piece female coupling set.

It may be more worthwhile if you buy a whole set of couplers and plugs, readying yourself with additional replacements for any future problems you may face or compressed air system expansion.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'about_air_compressors_com-banner-1','ezslot_8',121,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-banner-1-0')}; The first set is a La Lematec 15-piece female coupling set.  After wrapping the plastic bag tightly, use some electrical tape to place the plastic on the place. I have a swivel on my brad nailer and the female quick connect leaks every time I set the thing down. Spray a soap solution in the suspected area of the pipe and you will find air blowing bubbles if there is any leakage. Nothing more enjoyable than. If you find it at the joint, then it would be better to replace the hose. Those other terms only cause confusion. Also I've never seem a quick connect permanently attached to a compressor before, you sure it's not just tight? Need air compressor to run 4 roofing nail guns, Sears air compressor pressure switch issues, Ingersoll Rand 5 HP motor hums but wont start, Air Compressor Overheating: 9 Most Common Reasons & How to Prevent It, UST Power System Plus Air Compressor Wont Reach Cut-Out Pressure, Emglo Air Compressor Wont Reach Cut-Out Pressure, Makita Air Compressor Wont Reach Cut-Out Pressure, Air Compressor Wont Reach Cut-Out Pressure Troubleshooting, Sanborn Air Compressors Information, Manuals, Service Locations, Top Air Compressor Manufacturers & Air Compressor Brands List, Plumbing an Air Compressor Setup Running Air Compressor Lines In A Garage, How To Calculate CFM of Air Compressors PSI to CFM Conversion, Identifying An Older Air Compressor Serial Numbers, Photos & Antique Air Compressor Identification, Air Compressor Troubleshooting, Solutions, Common Problems & Causes, How To Choose An Air Compressor Buying Air Compressors 2021, Compressed Air Treatment Guide Compressed Air Preperation And Treatment, What is Compressed Air?

After wrapping the plastic bag tightly, use some electrical tape to place the plastic on the place. I have a swivel on my brad nailer and the female quick connect leaks every time I set the thing down. Spray a soap solution in the suspected area of the pipe and you will find air blowing bubbles if there is any leakage. Nothing more enjoyable than. If you find it at the joint, then it would be better to replace the hose. Those other terms only cause confusion. Also I've never seem a quick connect permanently attached to a compressor before, you sure it's not just tight? Need air compressor to run 4 roofing nail guns, Sears air compressor pressure switch issues, Ingersoll Rand 5 HP motor hums but wont start, Air Compressor Overheating: 9 Most Common Reasons & How to Prevent It, UST Power System Plus Air Compressor Wont Reach Cut-Out Pressure, Emglo Air Compressor Wont Reach Cut-Out Pressure, Makita Air Compressor Wont Reach Cut-Out Pressure, Air Compressor Wont Reach Cut-Out Pressure Troubleshooting, Sanborn Air Compressors Information, Manuals, Service Locations, Top Air Compressor Manufacturers & Air Compressor Brands List, Plumbing an Air Compressor Setup Running Air Compressor Lines In A Garage, How To Calculate CFM of Air Compressors PSI to CFM Conversion, Identifying An Older Air Compressor Serial Numbers, Photos & Antique Air Compressor Identification, Air Compressor Troubleshooting, Solutions, Common Problems & Causes, How To Choose An Air Compressor Buying Air Compressors 2021, Compressed Air Treatment Guide Compressed Air Preperation And Treatment, What is Compressed Air?  Pro suggestion: Buy one of the best air compressor hose repair kit without compromising on the cost to ensure improved repair work. So you should measure the percentage of lost air by comparing the air compressor activate time and each load-unload cycle duration. If you have a damaged O-ring, the process to replace them is generally very simple and will only cost around $0.20-$0.50 per O-ring. Apart from this, walk around the compressor plan while it is to check if there is any problem. Now fit a coupler into both the cut hoses. We can never seem o eliminate them all, for very long anyway. Placing an O-ring inside the socket will stop the leaking between the end and the quick connect. Air compressor hose leakage is regular problem in air compressor systems. ac coolant system ring In the past, whenever I found a fitting which leaked, I would throw it away, and replace with new Milton fittings. This site is reader-supported and we earn commissions if you purchase products from retailers after clicking on a link from our site. Cooling body suit inside another insulated suit, Mathematica won't validate Fresnel Integral identity. For more information on how to repair an air hose, chat with a knowledgeable expert at your localNAPA AUTO PARTS store. Before ending up as a Professional Handyman, Ive spent countless hours exploring various hand and power tools on my own garage and inventory. Air leaks, possible in any part of the compressed air system, are commonly found at or around quick connections. your air compressor and check the joining to ensure it is not leaking anymore. Simply follow the process we have mentioned above to ensure proper repair of the compressor hose. Once you have found the joining area of two ends of the hose, now it is time to cut down the joining for fixing it with new parts. Your email address will not be published. No matter how good your air compressor is, it can always show some issues. This site will cover products like power drills, air compressors, saws, nail guns, screw guns, grinders, cutting tools, and many more.

Pro suggestion: Buy one of the best air compressor hose repair kit without compromising on the cost to ensure improved repair work. So you should measure the percentage of lost air by comparing the air compressor activate time and each load-unload cycle duration. If you have a damaged O-ring, the process to replace them is generally very simple and will only cost around $0.20-$0.50 per O-ring. Apart from this, walk around the compressor plan while it is to check if there is any problem. Now fit a coupler into both the cut hoses. We can never seem o eliminate them all, for very long anyway. Placing an O-ring inside the socket will stop the leaking between the end and the quick connect. Air compressor hose leakage is regular problem in air compressor systems. ac coolant system ring In the past, whenever I found a fitting which leaked, I would throw it away, and replace with new Milton fittings. This site is reader-supported and we earn commissions if you purchase products from retailers after clicking on a link from our site. Cooling body suit inside another insulated suit, Mathematica won't validate Fresnel Integral identity. For more information on how to repair an air hose, chat with a knowledgeable expert at your localNAPA AUTO PARTS store. Before ending up as a Professional Handyman, Ive spent countless hours exploring various hand and power tools on my own garage and inventory. Air leaks, possible in any part of the compressed air system, are commonly found at or around quick connections. your air compressor and check the joining to ensure it is not leaking anymore. Simply follow the process we have mentioned above to ensure proper repair of the compressor hose. Once you have found the joining area of two ends of the hose, now it is time to cut down the joining for fixing it with new parts. Your email address will not be published. No matter how good your air compressor is, it can always show some issues. This site will cover products like power drills, air compressors, saws, nail guns, screw guns, grinders, cutting tools, and many more.  But I've found it is often the quick coupler that leaks. The two "main" types are often referred to as "automotive" and "industrial", though each can have sub-types that are typically letter designations, e.g. Now look at the repair carefully and, hopefully, you wont find any leaks anymore. Then insert the barbed fitting all the way into the hose until the fitting is seated to end of the ferrule. How can websites that block your IP address be accessed with SmartDNS and can website owners do anything to stop it? First of all, the cost of energy is going to increase leaving you with an overly inflated electricity bill. With the hose kit, you will get clamps that will tighten up the hose with the kit. Plus, hold the plastic bag in place by wrapping it with electrical tape. Same when connecting a hose, sometimes you have to make sure you pull the attachment back all the way and keep it open until the relative parts are in place, flush and set, before you can make a good connection happen. How can we send radar to Venus and reflect it back on earth? Sizing An Air Compressor, Sizing An Air Compressor For Impact Wrench, Sizing An Air Compressor For Spray Painting, Sizing An Air Compressor For Double Acting Air Sander, Sizing An Air Compressor For An Air Stapler, Sizing An Air Compressor For Sandblasting, Spray Texture Gun Air Pressure Requirements, Sizing An Air Compressor For Car Detailing, Air Compressor Troubleshooting, Solutions & Common Problems, Air Compressor Repair DIY & Repair Centers, Why An Air Compressor Wont Build Pressure, Air Compressor Keeps Tripping Circuit Breaker Solved, Air Compressor Reset Button Keeps Tripping? At work we use the cheap crappy Grainger ones and my most used air tools and whip hose I'm lucky to get 2 months before they start leaking. Otherwise, a regular knife or kit is enough for cutting. Im bookmarking and will be tweeting this to my followers! Someone in my Facebook group shared this website with us so I came to give it a look. If you find anything wrong, then replace its connectors and valves or add some thread sealant to the affected area. Always buy the plugs/nipples in steel unless you live buy the ocean. Though the two main types are industrial and automotive, these also possess subtypes! Replace the hose and tube sections: Air hoses and tubes also tend to leak air. Tighten fasteners: This method of preventing air leakage is a bit time-consuming, but still effective for increasing the longevity of the air compressor. Save my name, email, and website in this browser for the next time I comment. Superb blog and brilliant design. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product. Start It's rare, but mistakes do happen, of course.

But I've found it is often the quick coupler that leaks. The two "main" types are often referred to as "automotive" and "industrial", though each can have sub-types that are typically letter designations, e.g. Now look at the repair carefully and, hopefully, you wont find any leaks anymore. Then insert the barbed fitting all the way into the hose until the fitting is seated to end of the ferrule. How can websites that block your IP address be accessed with SmartDNS and can website owners do anything to stop it? First of all, the cost of energy is going to increase leaving you with an overly inflated electricity bill. With the hose kit, you will get clamps that will tighten up the hose with the kit. Plus, hold the plastic bag in place by wrapping it with electrical tape. Same when connecting a hose, sometimes you have to make sure you pull the attachment back all the way and keep it open until the relative parts are in place, flush and set, before you can make a good connection happen. How can we send radar to Venus and reflect it back on earth? Sizing An Air Compressor, Sizing An Air Compressor For Impact Wrench, Sizing An Air Compressor For Spray Painting, Sizing An Air Compressor For Double Acting Air Sander, Sizing An Air Compressor For An Air Stapler, Sizing An Air Compressor For Sandblasting, Spray Texture Gun Air Pressure Requirements, Sizing An Air Compressor For Car Detailing, Air Compressor Troubleshooting, Solutions & Common Problems, Air Compressor Repair DIY & Repair Centers, Why An Air Compressor Wont Build Pressure, Air Compressor Keeps Tripping Circuit Breaker Solved, Air Compressor Reset Button Keeps Tripping? At work we use the cheap crappy Grainger ones and my most used air tools and whip hose I'm lucky to get 2 months before they start leaking. Otherwise, a regular knife or kit is enough for cutting. Im bookmarking and will be tweeting this to my followers! Someone in my Facebook group shared this website with us so I came to give it a look. If you find anything wrong, then replace its connectors and valves or add some thread sealant to the affected area. Always buy the plugs/nipples in steel unless you live buy the ocean. Though the two main types are industrial and automotive, these also possess subtypes! Replace the hose and tube sections: Air hoses and tubes also tend to leak air. Tighten fasteners: This method of preventing air leakage is a bit time-consuming, but still effective for increasing the longevity of the air compressor. Save my name, email, and website in this browser for the next time I comment. Superb blog and brilliant design. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product. Start It's rare, but mistakes do happen, of course.  And for what ever reason M fittings DO NOT WORK with these. spigot garden fix hose leaks His work has been featured in Car Craft, Hot Rod, Rod & Custom, Truckin, Mopar Muscle, and many more. I tried the V fittings and to be honest theyre nice but suck lol. JavaScript is disabled. A pressure gauge is an effective tool that helps check the leakage in the compressed air pipeline easily. This will allow you to use an industrial type end with an automotive quick-connect socket!if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'about_air_compressors_com-box-4','ezslot_7',120,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-box-4-0')}; Before purchasing a replacement quick connect for your air compressor its important that you check your manual and find out exactly what type of fitting you have. Air compressor is a great thing for modern works. I don't have any leaks now. This will also allow you to use an industrial (type D) end with an automotive (type C) Quick Connect socket. M-STYLE: The industry standard coupler. As soon as I attach the hose, I can't get it above 60 PSI.

And for what ever reason M fittings DO NOT WORK with these. spigot garden fix hose leaks His work has been featured in Car Craft, Hot Rod, Rod & Custom, Truckin, Mopar Muscle, and many more. I tried the V fittings and to be honest theyre nice but suck lol. JavaScript is disabled. A pressure gauge is an effective tool that helps check the leakage in the compressed air pipeline easily. This will allow you to use an industrial type end with an automotive quick-connect socket!if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'about_air_compressors_com-box-4','ezslot_7',120,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-box-4-0')}; Before purchasing a replacement quick connect for your air compressor its important that you check your manual and find out exactly what type of fitting you have. Air compressor is a great thing for modern works. I don't have any leaks now. This will also allow you to use an industrial (type D) end with an automotive (type C) Quick Connect socket. M-STYLE: The industry standard coupler. As soon as I attach the hose, I can't get it above 60 PSI.  The machine is so useful and easy to use that you can use for both home and professional projects. This will fit more about-air-compressors.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. At work we use the cheap crappy Grainger ones and my most used air tools and whip hose I'm lucky to get 2 months before they start leaking. The best sealant is PTFE tape or PTFE dope. I'll double check the quick connect on the compressor to see if it can unscrew.

The machine is so useful and easy to use that you can use for both home and professional projects. This will fit more about-air-compressors.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. At work we use the cheap crappy Grainger ones and my most used air tools and whip hose I'm lucky to get 2 months before they start leaking. The best sealant is PTFE tape or PTFE dope. I'll double check the quick connect on the compressor to see if it can unscrew.  You may not have installed the coupling correctly4. air fittings types tool hose compressor fitting quick connect couplings prevent leaking different legacy lines system manufacturing stack If the tank gets to 140 and you get 60 at the hose your regulator may be bad.

You may not have installed the coupling correctly4. air fittings types tool hose compressor fitting quick connect couplings prevent leaking different legacy lines system manufacturing stack If the tank gets to 140 and you get 60 at the hose your regulator may be bad.  I have never had a leak. dishwasher gap air open Besides, the reader will learn how to detect air compressor leaks and effectively keep the air compressor from leakage. Repeat the Use a screwdriver for tightening. Can I reduce the grinding and humming noise from my portable air con's compressor? The best answers are voted up and rise to the top, Start here for a quick overview of the site, Detailed answers to any questions you might have, Discuss the workings and policies of this site, Learn more about Stack Overflow the company. The more you secure the system, the less compressed air leakage you will enjoy. Want to brag about your gorgeous compressor rebuild? leaking Luckily, the guide will offer a straightforward and quick way to solve the issue. Sam Morgan is a general contractor based in Charlotte, North Carolina. Milton), and the same brand of both fittings. Your email address will not be published.

I have never had a leak. dishwasher gap air open Besides, the reader will learn how to detect air compressor leaks and effectively keep the air compressor from leakage. Repeat the Use a screwdriver for tightening. Can I reduce the grinding and humming noise from my portable air con's compressor? The best answers are voted up and rise to the top, Start here for a quick overview of the site, Detailed answers to any questions you might have, Discuss the workings and policies of this site, Learn more about Stack Overflow the company. The more you secure the system, the less compressed air leakage you will enjoy. Want to brag about your gorgeous compressor rebuild? leaking Luckily, the guide will offer a straightforward and quick way to solve the issue. Sam Morgan is a general contractor based in Charlotte, North Carolina. Milton), and the same brand of both fittings. Your email address will not be published.  the hose. In a shack by the river in Central Arkansas, Littlestown, PA _ 6 miles south of Gettysburg, http://toolguyd.com/quick-guide-to-air-line-couplers-plugs/. The high-quality durable brass fittings are interchangeable/compatible with most manufacturers. Guides to fix a leaky air compressor hose, Different ways to find out if an air compressor leaks, How to prevent air compressor from leakage, FAQs on How to fix a leaky Air Compressor hose, How to make an air compressor from an old refrigerator. Nothing more enjoyable than listening to air leaking all day, I'm very laid back but it drives me up a wall. However, if you think the leakage is happening somewhere else, you may need to replace the entire hose. For the You are correct that it is a good idea to use teflon tape on the threaded fittings, however no sealant is required or advised on the quick-connect part itself. connects Air Compressor Repair DIY Repair or Replace? Industrial type couplers are Type D and are 1/4, whilst automotive couplers are Type C or Type G and can be of sizes 1/4 and 3/8 respectively. hose fire leaking connector water shutterstock vectors But dont tighten excessively as it can break the hose clamps. I found this question with information about pipe dope: This does not really seem to say anything that's not already in the other answers. secure connection between two ends of the hose, you can apply a plastic bag on A life-long gearhead, Jefferson Bryant spends more time in the shop than anywhere else. If you got quick connect couplings at a big home improvement store there are different types. Next, open the crimping tool and load the dies for the correct hose size. I would advise that if theres any evident damage or no issue with the seal then replace your quick connect with a new one! Therefore, it becomes quite easy for them to become damaged and begin to leak. I only use milton or ampro for air connections, but never leave any equipment under pressure - including the tank. But the repair can be time-consuming and costly if you apply the wrong method. First, the hose is cut. Why are the products of Grignard reaction on an alpha-chiral ketone diastereomers rather than a racemate? Why did the Federal reserve balance sheet capital drop by 32% in Dec 2015? compressed leaks air system basics bottom getting occur hoses fittings commonly figure Despite this, it is worthwhile to routinely check the air compressor so you can find and solve the problem in the initial stage. If you have any questions regarding air compressor quick connect leaks, please leave a comment below, with a photo if applicable, so that someone may help you! Dont worry; we will guide you to solving the problem like a pro. Copyright National Automotive Parts Association. Air Compressor Quick Connect Coupler Won't Latch. hose leaking garden leak stop spigot does why connection flipboard email Now it is time to check the connection if it is working perfectly. Dont fret, for about $5, you can repair an air hose yourself. The air compressor is the busy part that transfers compressed air from the air compressor to the air tool to complete the desired task. SHOP GRADE - performance tested & built to last from 100% solid brass & steel designed for all-day use working with air compressor tools, hoses, and airline accessories in the garage or shop. Milton Industries has also published a document that may help identify the type of plug you have, though their letter designations may not exactly match those of other manufacturers. It may be the wrong size coupling for your compressed air system. What would the term for pomegranate orchard be in latin or ancient greek? Follow these steps: I previously mentioned that it was possible you have two incompatible types connected to one another, if this is the case you could purchase an O-ring and place it inside the socket to stop the leak between the two. For a better experience, please enable JavaScript in your browser before proceeding. Here I am going to share the whole process step by step so that it becomes easy for you. Can You Leave Your Car on While Pumping Gas? You need to identify the exact location and the exact part that causing the leakage. The majority are designed to seal internally using O-rings hence there typically is no need to use PTFE tape or dope on the threads. Then make sure that the air hose connection is properly sealed. Otherwise head to the local big box store with your male coupling that leaks, and look for a similar-while-slightly-different male coupler to try. Copyright 2022 TheHandyTool. I hat to break it to you but Amflo is now mostly Chinese.

the hose. In a shack by the river in Central Arkansas, Littlestown, PA _ 6 miles south of Gettysburg, http://toolguyd.com/quick-guide-to-air-line-couplers-plugs/. The high-quality durable brass fittings are interchangeable/compatible with most manufacturers. Guides to fix a leaky air compressor hose, Different ways to find out if an air compressor leaks, How to prevent air compressor from leakage, FAQs on How to fix a leaky Air Compressor hose, How to make an air compressor from an old refrigerator. Nothing more enjoyable than listening to air leaking all day, I'm very laid back but it drives me up a wall. However, if you think the leakage is happening somewhere else, you may need to replace the entire hose. For the You are correct that it is a good idea to use teflon tape on the threaded fittings, however no sealant is required or advised on the quick-connect part itself. connects Air Compressor Repair DIY Repair or Replace? Industrial type couplers are Type D and are 1/4, whilst automotive couplers are Type C or Type G and can be of sizes 1/4 and 3/8 respectively. hose fire leaking connector water shutterstock vectors But dont tighten excessively as it can break the hose clamps. I found this question with information about pipe dope: This does not really seem to say anything that's not already in the other answers. secure connection between two ends of the hose, you can apply a plastic bag on A life-long gearhead, Jefferson Bryant spends more time in the shop than anywhere else. If you got quick connect couplings at a big home improvement store there are different types. Next, open the crimping tool and load the dies for the correct hose size. I would advise that if theres any evident damage or no issue with the seal then replace your quick connect with a new one! Therefore, it becomes quite easy for them to become damaged and begin to leak. I only use milton or ampro for air connections, but never leave any equipment under pressure - including the tank. But the repair can be time-consuming and costly if you apply the wrong method. First, the hose is cut. Why are the products of Grignard reaction on an alpha-chiral ketone diastereomers rather than a racemate? Why did the Federal reserve balance sheet capital drop by 32% in Dec 2015? compressed leaks air system basics bottom getting occur hoses fittings commonly figure Despite this, it is worthwhile to routinely check the air compressor so you can find and solve the problem in the initial stage. If you have any questions regarding air compressor quick connect leaks, please leave a comment below, with a photo if applicable, so that someone may help you! Dont worry; we will guide you to solving the problem like a pro. Copyright National Automotive Parts Association. Air Compressor Quick Connect Coupler Won't Latch. hose leaking garden leak stop spigot does why connection flipboard email Now it is time to check the connection if it is working perfectly. Dont fret, for about $5, you can repair an air hose yourself. The air compressor is the busy part that transfers compressed air from the air compressor to the air tool to complete the desired task. SHOP GRADE - performance tested & built to last from 100% solid brass & steel designed for all-day use working with air compressor tools, hoses, and airline accessories in the garage or shop. Milton Industries has also published a document that may help identify the type of plug you have, though their letter designations may not exactly match those of other manufacturers. It may be the wrong size coupling for your compressed air system. What would the term for pomegranate orchard be in latin or ancient greek? Follow these steps: I previously mentioned that it was possible you have two incompatible types connected to one another, if this is the case you could purchase an O-ring and place it inside the socket to stop the leak between the two. For a better experience, please enable JavaScript in your browser before proceeding. Here I am going to share the whole process step by step so that it becomes easy for you. Can You Leave Your Car on While Pumping Gas? You need to identify the exact location and the exact part that causing the leakage. The majority are designed to seal internally using O-rings hence there typically is no need to use PTFE tape or dope on the threads. Then make sure that the air hose connection is properly sealed. Otherwise head to the local big box store with your male coupling that leaks, and look for a similar-while-slightly-different male coupler to try. Copyright 2022 TheHandyTool. I hat to break it to you but Amflo is now mostly Chinese.

air I have one tool/connection that does this.

air I have one tool/connection that does this.  What does "Check the proof of theorem x" mean as a comment from a referee on a mathematical paper?

What does "Check the proof of theorem x" mean as a comment from a referee on a mathematical paper?  If you find it hard to put the coupler in the tube, heap it up to the end of the hose about 1/2, using a lighter to complete the task easily. Connect and share knowledge within a single location that is structured and easy to search. Air compressor quick connect leaks can also occur due to a problem with the fittings sealing. I used to work for them and they started making the change over 10 years ago. Be especially leery of the cast "white metal" ones sold at discount stores. rev2022.7.29.42699. Both are good. And whatever Ive learned from 10+ years of DIY-ship, I share on this little corner of the internet. Prices pulled from the Amazon Product Advertising API on: Product prices and availability are accurate as of the date/time indicated and are subject to change.

If you find it hard to put the coupler in the tube, heap it up to the end of the hose about 1/2, using a lighter to complete the task easily. Connect and share knowledge within a single location that is structured and easy to search. Air compressor quick connect leaks can also occur due to a problem with the fittings sealing. I used to work for them and they started making the change over 10 years ago. Be especially leery of the cast "white metal" ones sold at discount stores. rev2022.7.29.42699. Both are good. And whatever Ive learned from 10+ years of DIY-ship, I share on this little corner of the internet. Prices pulled from the Amazon Product Advertising API on: Product prices and availability are accurate as of the date/time indicated and are subject to change.